Gradient porous implant with drug carrying function

A gradient porous, implant technology, applied in dental implants, prostheses, medical science, etc., can solve the problem that the mechanical properties cannot meet the high-frequency and high-strength force requirements of the oral environment, the elastic modulus does not match, and the healing time is shortened, etc. problem, achieve the effect of promoting early adhesion and osteogenic differentiation, reducing elastic modulus, and reducing stress shielding phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with the examples, which are only used to explain the present invention, and do not constitute a limitation to the protection scope of the present invention.

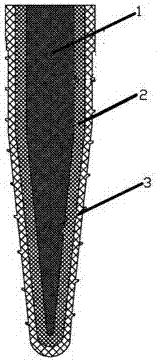

[0019] Such as figure 1 As shown, this embodiment provides a gradient porous implant with drug-carrying function, the implant includes a dense core 1, a transition layer 2 and a porous layer 3, and the implant is sequentially dense core from inside to outside Body 1, transition layer 2 and porous layer 3 with interconnected pore structure. The size of the pores in the porous layer 3 is maintained at 200-500 μm, the cross-sectional shape of the pores is a rhombus that is conducive to the growth of bone tissue, the pore diameter is greater than 300 μm, the porosity is 80%, the pores are in a spiral distribution, and three types of pores are respectively set. The intervals are 30°, 45°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Gap | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com