Cross-linked polyglutamic acid gel microsphere suspension for injection and preparation method of suspension

A technology of polyglutamic acid gel microspheres and polyglutamic acid gel, which is used in pharmaceutical formulations, medical science, prostheses, etc., can solve the problems of large injection resistance, high solution viscosity, and syringe bursting. , to achieve the effect of small bolus resistance, small particle size and reduced bolus resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

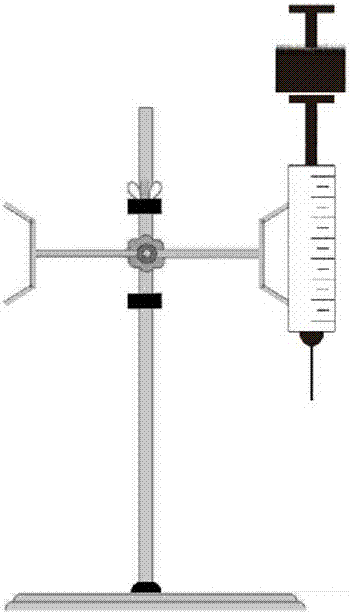

Image

Examples

Embodiment 1

[0022] Weigh 5 g of polyglutamic acid, add 100 mL of distilled water to dissolve to obtain polyglutamic acid aqueous solution. Take 10mL of Span 80 and 30ml of Tween 80 respectively, put them into 160mL of liquid paraffin, stir and mix well. Add polyglutamic acid aqueous solution into liquid paraffin containing mixed emulsifier, and make polyglutamic acid microspheres through membrane emulsification. Observation by oil microscope, the polyglutamic acid gel microspheres are spherical. When more than 90% of the microspheres have a particle size of <5 μm, add 0.25 mL polyethylene glycol glycidyl ether, heat at 45 °C and stir at 50 rpm for 12 hours to cross-link. The liquid layer was removed by centrifugation, washed successively with petroleum ether, acetone and ethanol, and finally the cross-linked polyglutamic acid microspheres were suspended in 0.9% saline to obtain a suspension of cross-linked polyglutamic acid gel microspheres, which could be Injects smoothly through a 30G ...

Embodiment 2

[0024] Weigh 25 g polyglutamic acid, add 100mL distilled water to dissolve to obtain polyglutamic acid aqueous solution. Take 30mL of Span 80 and 10mL of Tween 80 respectively to make emulsifier. Take 1000mL of liquid paraffin and 60mL of petroleum ether with a boiling range of 60°C to 90°C, then add the prepared emulsifier, stir and mix well. The polyglutamic acid aqueous solution is added to the oil phase containing emulsifier, and the polyglutamic acid microspheres are prepared by emulsifying through a homogenizer. Observation by oil microscope, the polyglutamic acid gel microspheres are spherical, when more than 90% of the microspheres have a particle size <5 μm, add 10 mL of ethylene glycol glycidyl ether, heat at 75 °C and stir at 500 rpm for 4 h to cross-link. The liquid layer was removed by centrifugation, washed with chloroform and ethanol in turn, and finally the cross-linked polyglutamic acid microspheres were suspended in physiological saline containing 0.5% proca...

Embodiment 3

[0026] Weigh 12g polyglutamic acid, add 100mL distilled water to dissolve to obtain polyglutamic acid aqueous solution. Take 30mL of Span 80 and 30mL of Tween 80 respectively to make emulsifier. Take 1000mL of liquid paraffin, add 40mL of petroleum ether with a boiling range of 60°C to 90°C, then add the prepared emulsifier, stir and mix well. The polyglutamic acid aqueous solution is added to the oil phase containing emulsifier, and the polyglutamic acid microspheres are prepared by emulsifying through a homogenizer. Observation by oil microscope, the polyglutamic acid gel microspheres are spherical, when more than 90% of the microspheres have a particle size of <5 μm, add 2.4mL ethylene glycol glycidyl ether, heat at 55°C and stir at 100rmp for 10h to cross-link. The liquid layer was removed by centrifugation, washed with chloroform and ethanol in turn, and finally the cross-linked polyglutamic acid microspheres were suspended in physiological saline containing 0.5% procain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com