Preparation method of vanadium nitride electrocatalyst and product

An electrocatalyst, vanadium nitride technology, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, hydrogen production, etc., can solve the problems of complex process, large size of vanadium nitride powder, and few applications in the field of electrocatalysis , to achieve the effect of simple process, short time consumption and uniform shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Step 1: Weigh 1.5g urea, 0.3g ammonium metavanadate, 0.3g cobalt nitrate hexahydrate, fully mix and grind for 20min;

[0024] Step 2: Put the raw materials obtained in Step 1 into a porcelain boat and react in a tube furnace with argon as the atmosphere. The heating rate is 5°C / min, the holding temperature is 700°C, and the holding time is 2h. After cooling, the obtained Powder with 0.5M H 2 SO 4 The solution was soaked for 10 hours (to remove impurities such as cobalt oxide), and the lower precipitate was washed with water and alcohol alternately six times, dried in an oven at 60°C for 6 hours, and ground in a mortar for 20 minutes to obtain a vanadium nitride electrocatalyst.

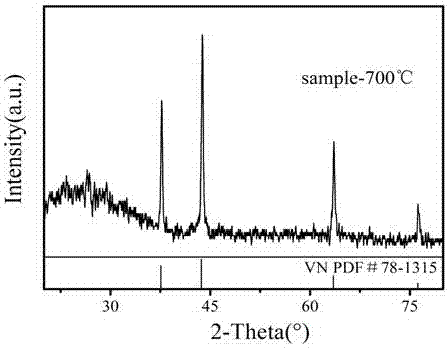

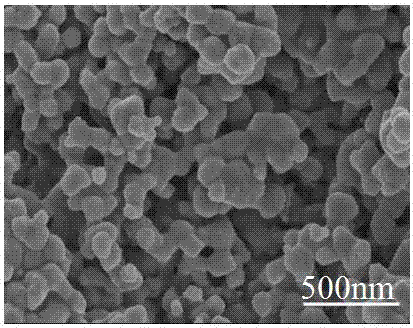

[0025] figure 1 It is the XRD spectrum of the nano-vanadium nitride prepared in this embodiment. It can be seen from the figure that the corresponding standard PDF card number of the sample is 78-1315, and the diffraction peak is sharp and high in intensity, indicating that the vanadium nitri...

Embodiment 2

[0027] Step 1: Weigh 1.5g urea, 0.3g ammonium metavanadate, 0.3g cobalt nitrate hexahydrate, fully mix and grind for 40min;

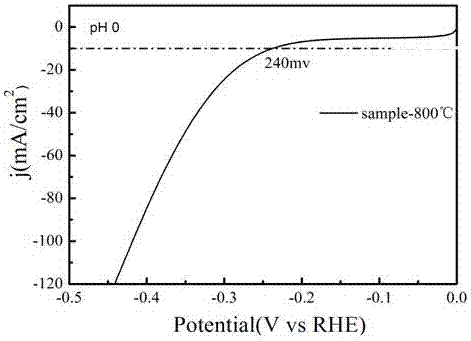

[0028] Step 2: Put the raw materials obtained in Step 1 into a porcelain boat and react in a tube furnace with nitrogen as the atmosphere. The heating rate is 8°C / min, the holding temperature is 800°C, and the holding time is 5h. The powder obtained after cooling Body with 0.5M H 2 SO 4 The solution was soaked for 15 hours (to remove impurities such as cobalt oxide), and the lower precipitate was washed alternately with water and isopropanol six times, dried in an oven at 60°C for 8 hours, and ground in a mortar for 30 minutes to obtain a vanadium nitride electrocatalyst.

Embodiment 3

[0030] Step 1: Weigh 1.5g urea, 0.2g ammonium metavanadate, 0.3g cobalt nitrate hexahydrate, fully mix and grind for 20min;

[0031] Step 2: Put the raw materials obtained in Step 1 into a porcelain boat, and react in a tube furnace with argon as the atmosphere. The heating rate is 10°C / min, the holding temperature is 900°C, and the holding time is 5h. After cooling, the obtained Powder with 0.5M H 2 SO 4 The solution was soaked for 20 hours (to remove impurities such as cobalt oxide), and the lower precipitate was washed with water and methanol alternately six times, dried in an oven at 60°C for 6 hours, and ground in a mortar for 40 minutes to obtain a vanadium nitride electrocatalyst.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com