Monodisperse ferrite micro-nano sheet and preparation method thereof

A ferrite, micro-nano technology, applied in the field of nano-composite, to achieve the effect of uniform particles, easy industrial application and promotion, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

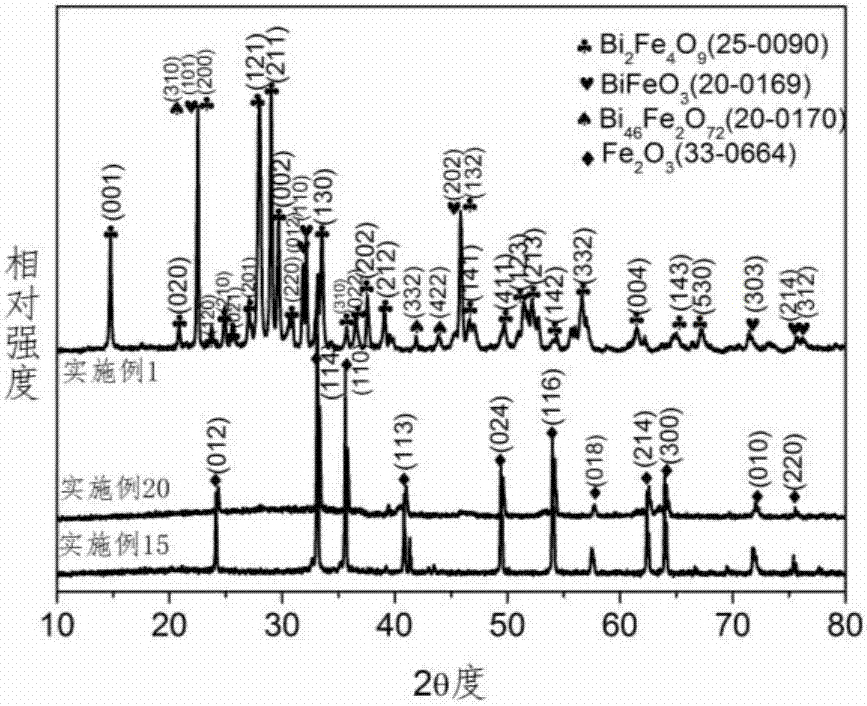

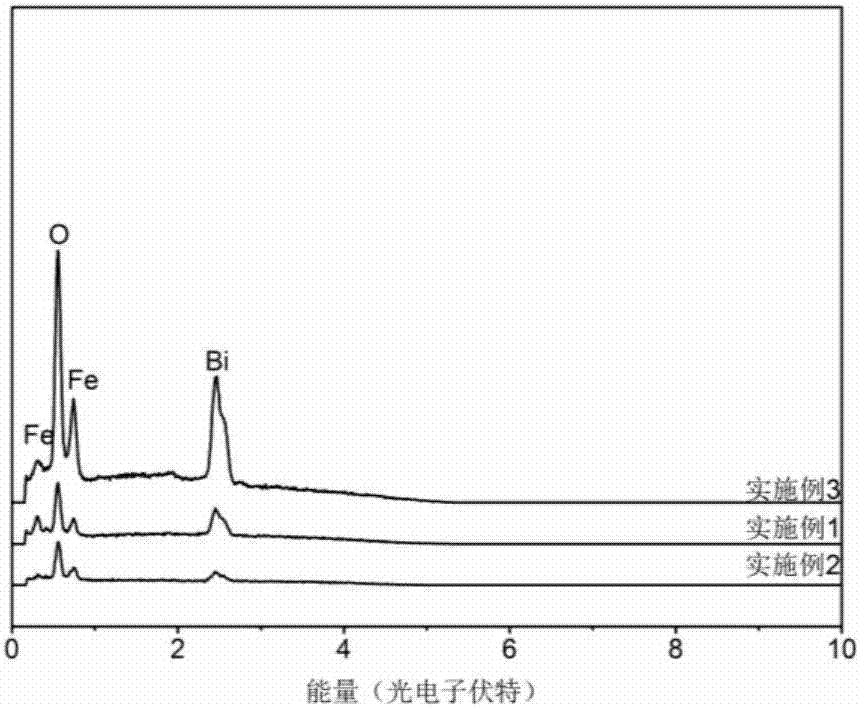

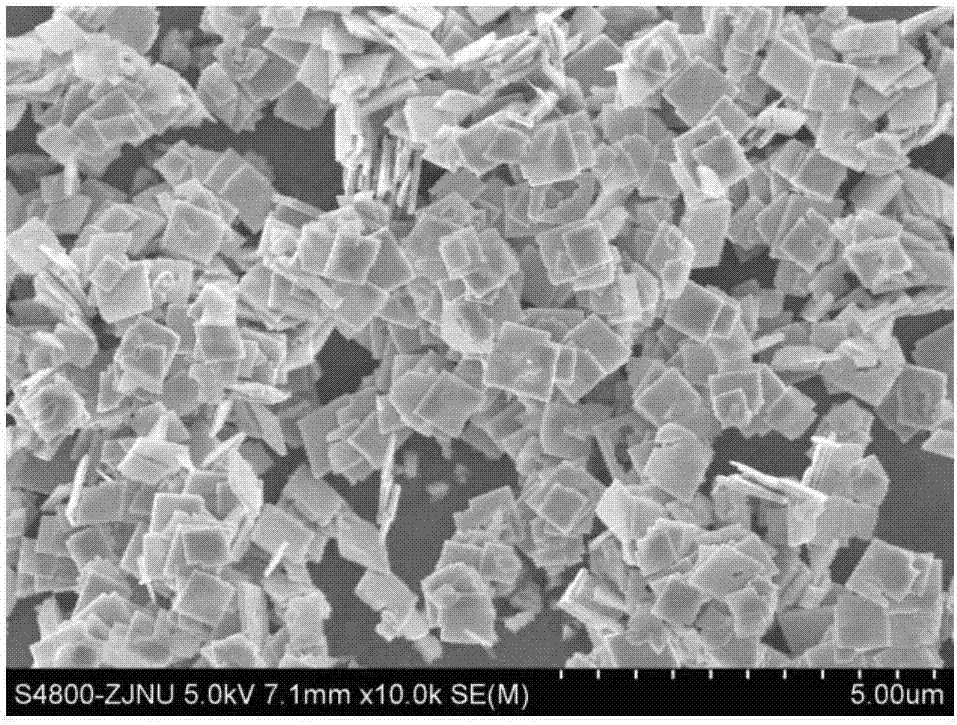

[0028] 50mL ethylene glycol, 2.425g (0.1mol / L) Bi(NO 3 ) 3 ·6H 2 O, 1.352g (0.1mol / L) FeCl 3 ·6H 2 O was added to the beaker one by one and stirred for 30 minutes. Add 200 mL of distilled water to the beaker and stir for 10 minutes, then add 5.5 mL of concentrated ammonia water dropwise, collect the precipitate by centrifugation, transfer the precipitate to the inner liner, add 40 mL of distilled water (concentration is 0.125 mol / L) and 8 g of NaOH (alkali and iron The ratio of the amount of salt to substance is 40) mixing and stirring for 0.5h. Finally, the lining was put into a stainless steel kettle to react at 140°C for 24 hours, cooled, washed by centrifugation, and dried at 80°C for 2 hours to obtain the desired monodisperse micro-nanosheets. The phase, elemental composition and morphology of the obtained product observed under the scanning electron microscope are as follows: Figure 1-3 shown. The product is Bi 2 Fe 4 o 9 、BiFeO 3 and Bi 46 Fe 2 o 72 , the...

Embodiment 2

[0030] Same step as Example 1, but the hydrothermal reaction time is 12h. The atomic ratio of Fe:Bi:O is 43:9:48, and the morphology of the obtained product observed under the scanning electron microscope is as follows: Figure 4 As shown, the obtained product is a quadrilateral micro-nano sheet with a side length of 530-890 nm and a thickness of 40-100 nm.

Embodiment 3

[0032] Same step as Example 1, but the hydrothermal reaction time is 48h. The atomic ratio of Fe:Bi:O is 37.3:14.2:48.5, and the morphology of the obtained product observed under the scanning electron microscope is as follows: Figure 5 As shown, the obtained product is a quadrilateral micro-nano sheet with a side length of 0.46-1.02 μm and a thickness of 40-120 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com