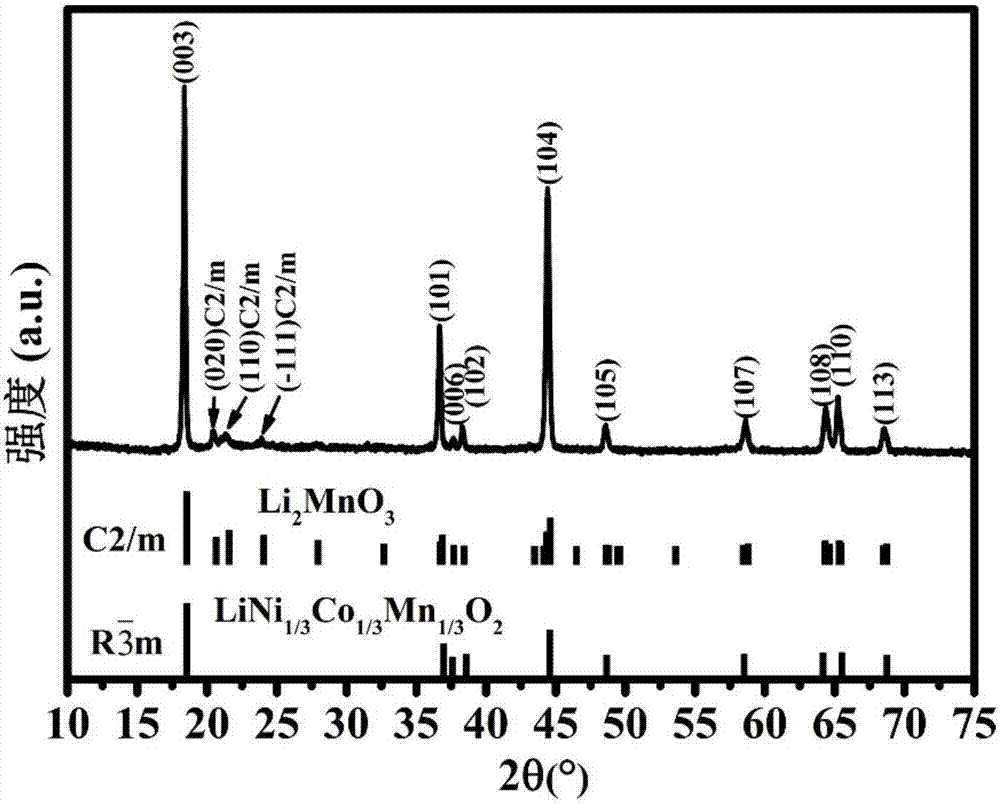

Lithium-rich manganese-based hollow nanosphere cathode material formed by winding slices and preparation method thereof

A hollow nanometer, lithium-rich manganese-based technology, applied in the fields of material synthesis and electrochemistry, achieves the effects of simple and easy operation, reduced diffusion paths, improved cycle stability and rate performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0074] The preparation steps of the high-capacity lithium-rich manganese-based hollow nanosphere positive electrode material wound by the sheet in this embodiment are as follows:

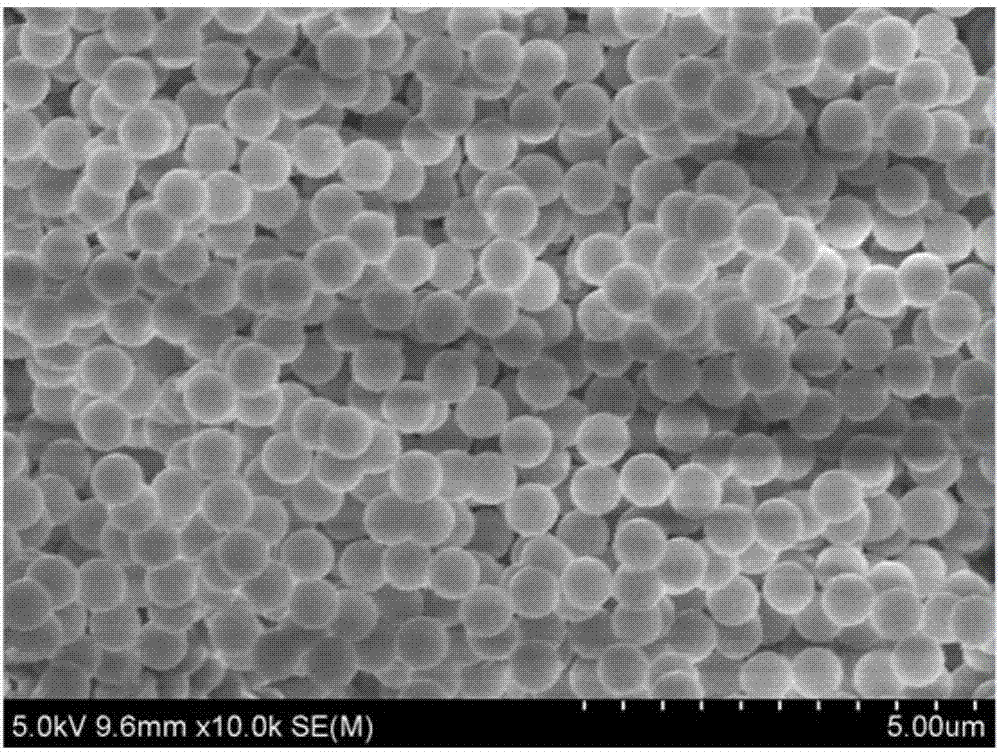

[0075] 1. Accurately weigh 0.305g of polyvinylpyrrolidone (PVP, Sigma, Mw=55000) with an electronic balance and dissolve it in 60mL of deionized water with vigorous stirring to form a transparent solution. 2 Remove the dissolved oxygen in the solution for 30min, and accurately measure 20mL styrene solution (Reagent ≥99%, Sigma-Aldrich) was added to the above PVP solution, the temperature was raised to 70°C and kept for 30min. 0.4 g of azobisisobutylamidine hydrochloride (V-50) initiator dissolved in 2.5 mL of deionized water was added to the above mixed solution of PVP and styrene, and kept at 70° C. for 24 h in a nitrogen atmosphere. Centrifuge, wash, and dry at 70°C to obtain polystyrene balls with a particle size of about 550 nm; figure 1 This is the SEM photo of the polystyrene balls prepare...

Embodiment 2

[0085] The preparation steps of the high-capacity lithium-rich manganese-based hollow nanosphere positive electrode material wound into thin sheets in this example are the same as those in Example 1, except that:

[0086] In step 1, 0.5 g of polyvinylpyrrolidone (PVP) was accurately weighed with an electronic balance, 30 mL of styrene solution was added to the above PVP solution, and the temperature was raised to 70° C. and kept for 30 min. 0.5 g of azobisisobutylamidine hydrochloride (V-50) initiator dissolved in 2.5 mL of deionized water was added to the above mixed solution of PVP and styrene, and kept at 70° C. for 24 h in a nitrogen atmosphere. Centrifuge, wash, and dry at 70°C to obtain polystyrene balls with a particle size of about 1.0 μm.

[0087] Using the same sulfonation method as in Example 1, the particle size of the polystyrene spheres after sulfonation was 900 nm.

[0088] In the high-capacity lithium-rich manganese-based hollow nanosphere anode material wound...

Embodiment 3

[0090] In this example, a high-capacity lithium-rich manganese-based hollow nanosphere anode material wound by flakes is prepared, and the specific steps are as follows:

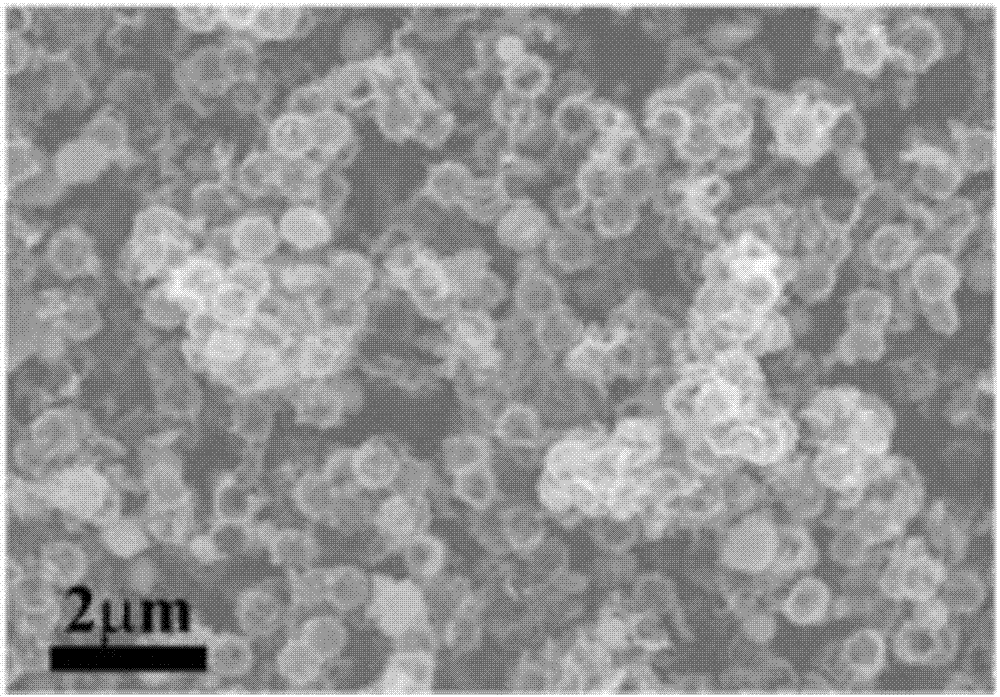

[0091] 1. Accurately weigh 0.1 g of polyvinylpyrrolidone (PVP, Sigma, Mw=55000) with an electronic balance and dissolve it in 60 mL of deionized water with vigorous stirring to form a transparent solution. 2 Remove the dissolved oxygen in the solution for 30min, and accurately measure 10mL styrene solution (Reagent ≥99%, Sigma-Aldrich) was added to the above PVP solution, the temperature was raised to 70°C and kept for 30min. 0.4 g of azobisisobutylamidine hydrochloride (V-50) initiator dissolved in 2.5 mL of deionized water was added to the above mixed solution of PVP and styrene, and kept at 70° C. for 24 h in a nitrogen atmosphere. Centrifuge, wash, and dry at 70°C to obtain polystyrene balls with a particle size of about 300 nm;

[0092] 2. Accurately measure 20mL of concentrated sulfuric acid (AR, 9...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com