Low thermal expansion cathode material for solid oxide fuel cell and preparation method thereof

A solid oxide and cathode material technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of reducing the overall thermal expansion coefficient of the composite cathode, weakening the performance of the composite cathode, and reducing the electrical performance, achieving low cost and simple preparation method. , the effect of simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

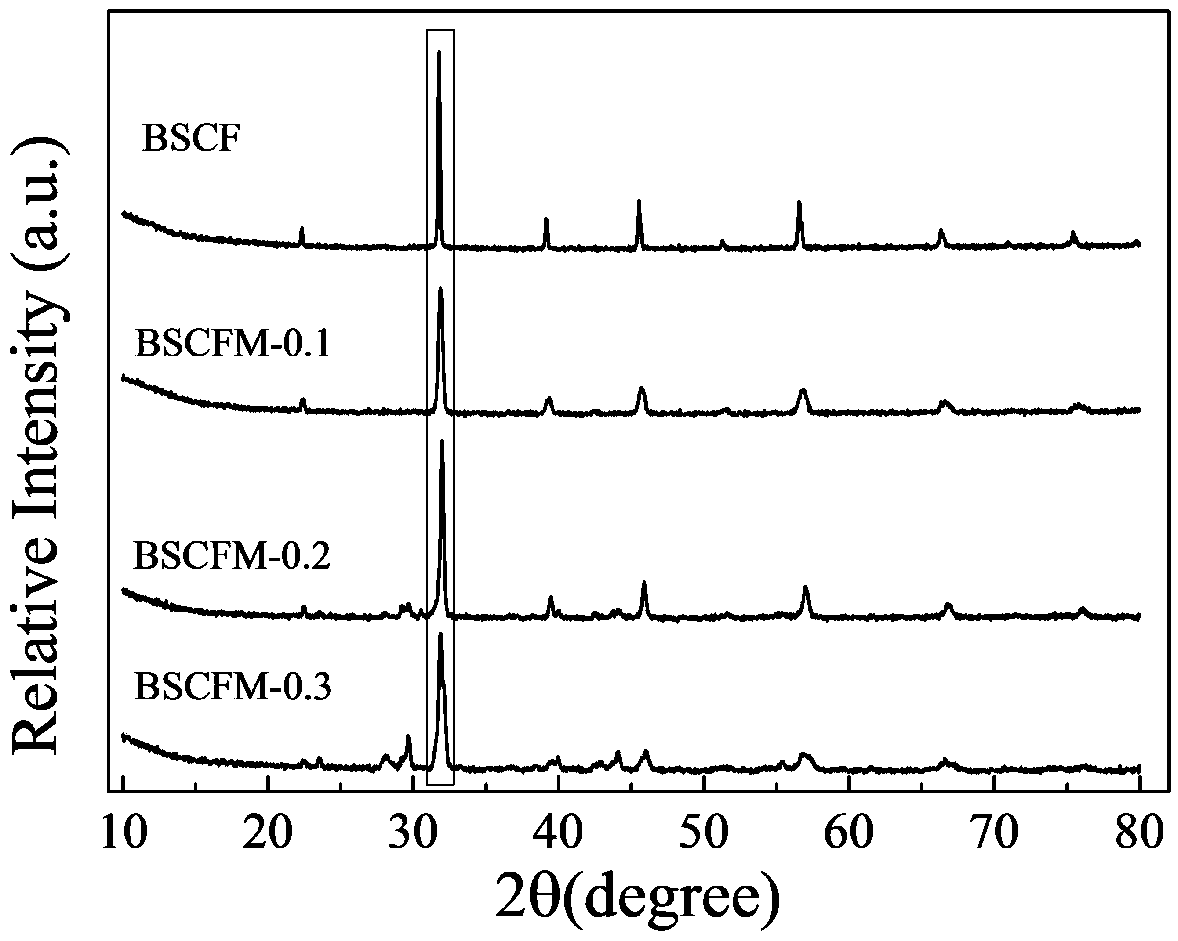

[0024] Prepare BSCF, where x=0;

[0025] 1) Before weighing, Ba(NO 3 ) 2 ,Sr(NO 3 ) 2 ,Co(NO 3 ) 2 ·6H 2 O,Fe(NO 3 ) 3 9H 2 O placed in a dry box 40 o C dried for 3 hours;

[0026] 2) Dissolve the weighed EDTA in ammonia solution and set aside;

[0027] 3) Ba(NO 3 ) 2 ,Sr(NO 3 ) 2 ,Co(NO 3 ) 2 ·6H 2 O,Fe(NO 3 ) 3 9H 2 O powder is weighed according to the molar ratio of 0.5:0.5:0.8:0.2, and the four raw materials are added to EDTA-ammonia solution and mixed, and the mixed solution is stirred on a heatable magnetic stirrer, and the heating temperature is set to 80 o C;

[0028] 4) After the nitrate is fully dissolved, add citric acid and adjust the pH value of the solution to 5 with ammonia water;

[0029] 5) Keep the solution temperature at 80 o C, until the gel is formed;

[0030] 6) Place the colloid at 85 o Dry in an oven at C for 20 hours, then increase the oven temperature to 110 o C placed for 6 hours until completely dry;

[0031] 7) Precursor...

Embodiment 2

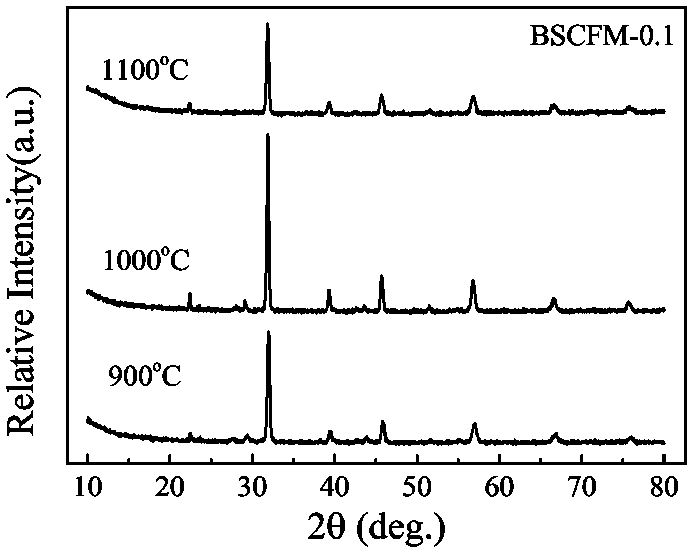

[0037] Prepare BSCFM-0.1, where x=0.1;

[0038] 1) Before weighing, Ba(NO 3 ) 2 ,Sr(NO 3 ) 2 ,Co(NO 3 ) 2 ·6H 2 O,Fe(NO 3 ) 3 9H 2 O, Mn(NO 3 ) 2 ·6H 2 O placed in a dry box 40 o C dried for 3 hours;

[0039] 2) Dissolve the weighed EDTA in ammonia solution and set aside;

[0040] 3) Ba(NO 3 ) 2 , Sr(NO 3 ) 2 , Co(NO 3 ) 2 ·6H 2 O, Fe(NO 3 ) 3 9H 2 O, Mn(NO 3 ) 2 ·6H 2 O powder is weighed according to the molar ratio of 0.5:0.5:0.7:0.2:0.1, and the five raw materials are mixed in EDTA-ammonia solution, and the mixed solution is stirred on a heatable magnetic stirrer, and the heating temperature is set to 80 o C;

[0041] 4) After the nitrate is fully dissolved, add citric acid and adjust the pH value of the solution to 5 with ammonia water;

[0042] 5) Keep the solution temperature at 80 o C, until the gel is formed;

[0043] 6) Place the colloid at 85 o Dry in an oven at C for 20 hours, then increase the oven temperature to 110 o C placed for ...

Embodiment 3

[0051] Prepare BSCFM-0.3, where x=0.3;

[0052] 1) Before weighing, Ba(NO 3 ) 2 , Sr(NO 3 ) 2 , Co(NO 3 ) 2 ·6H 2 O, Fe(NO 3 ) 3 9H 2 O, Mn(NO 3 ) 2 ·6H 2 O placed in a dry box 40 o C dried for 3 hours;

[0053] 2) Dissolve the weighed EDTA in ammonia solution and set aside;

[0054] 3) Ba(NO 3 ) 2 , Sr(NO 3 ) 2 , Co(NO 3 ) 2 ·6H 2 O, Fe(NO 3 ) 3 9H 2 O, Mn(NO 3 ) 2 ·6H 2 O powder is weighed according to the molar ratio of 0.5:0.5:0.5:0.2:0.3, and the five raw materials are mixed in EDTA-ammonia solution, and the mixed solution is stirred on a heatable magnetic stirrer, and the heating temperature is set to 80 o C;

[0055] 4) After the nitrate is fully dissolved, add citric acid and adjust the pH value of the solution to 5 with ammonia water;

[0056] 5) Keep the solution temperature at 80 o C, until the gel is formed;

[0057] 6) Place the colloid at 85 o Dry in an oven at C for 20 hours, then increase the oven temperature to 110 o C placed f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com