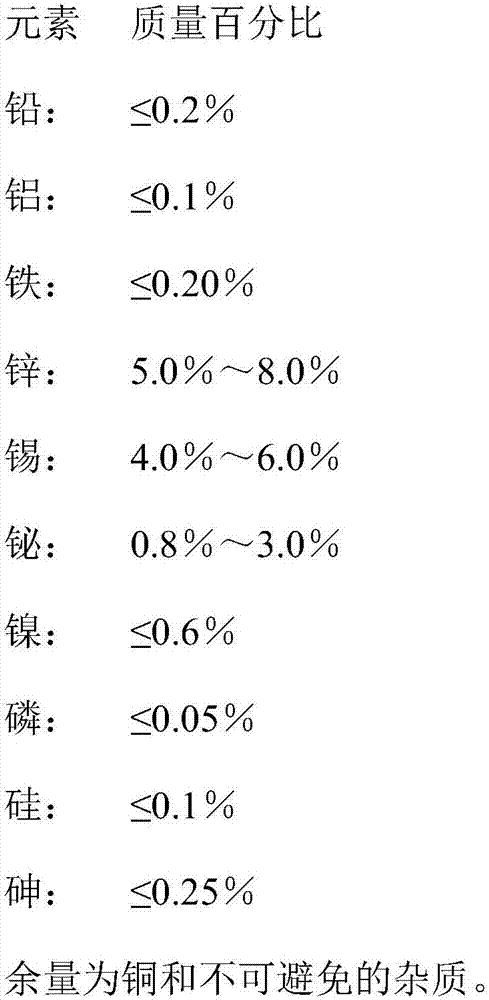

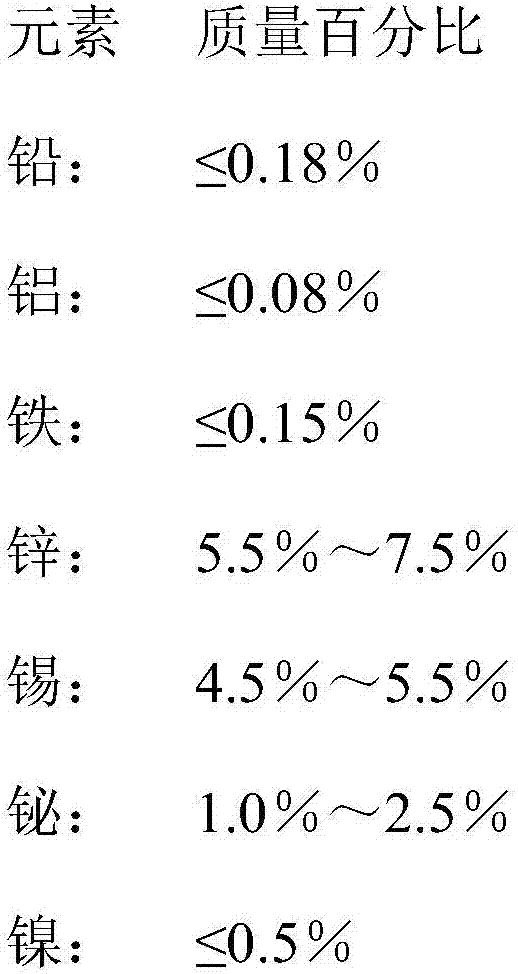

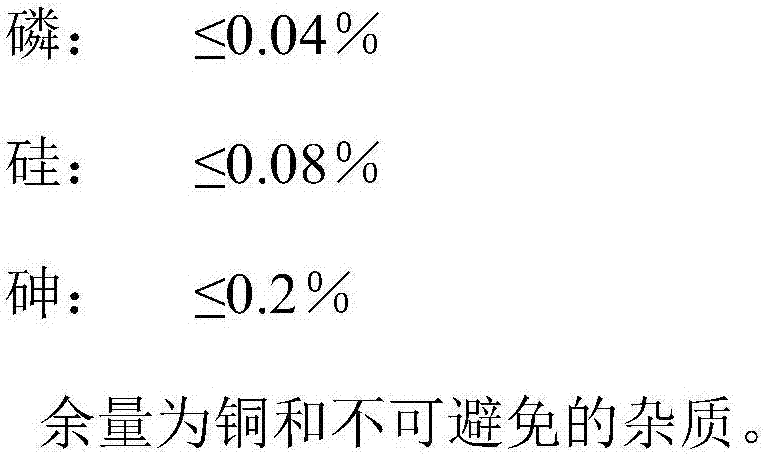

Lead-free environment-friendly bismuth bronze alloy material

An alloy material, bismuth bronze technology, which is applied in the field of lead-free environment-friendly bismuth bronze alloy material, can solve the problems of lowering casting performance and affecting application, and achieves the effects of improving fluidity, facilitating gravity casting, and excellent casting performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention is further described below with specific embodiment: the preparation method of lead-free environmental protection bismuth bronze alloy material is as follows:

[0015] Copper+tin+charcoal→melting→adding copper-bismuth alloy→stirring→zinc, stirring evenly→P-Cu→refining→sampling, pre-furnace analysis, composition adjustment→slagging, standing→out of the furnace and pouring,

[0016] The first step is to preheat the power frequency induction furnace, select cathode copper, electrolytic tin, and feed into the power frequency induction furnace;

[0017] The second step is to gradually heat the power frequency induction furnace to melt the raw materials;

[0018] The third step is to add copper-bismuth master alloy;

[0019] The fourth step is to add zinc after fully stirring to make the alloy melt mix evenly;

[0020] The fifth step is to add refining agent and stir again;

[0021] The sixth step is to sample and analyze the alloy melt after fully st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com