Method of growing Ga2O3 single crystals by way of closed tube chemical vapor transport

A transmission method and chemical vapor phase technology, which is applied in the field of compound semiconductor material preparation, can solve the problems of consuming carrier gas, increasing production costs, and small single crystal size, and achieve the effects of improving growth efficiency, reducing equipment expenses, and large crystal size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

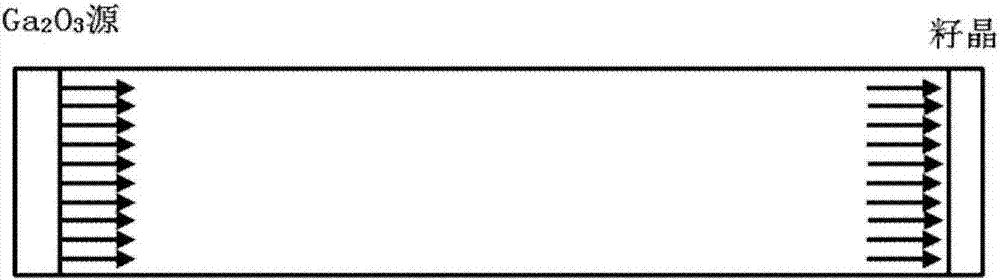

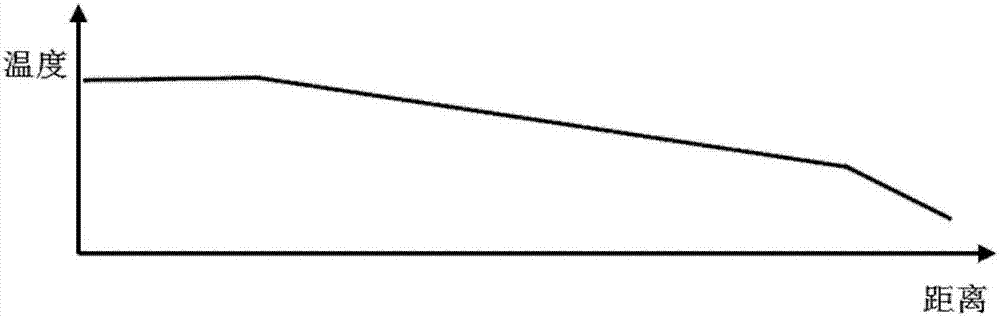

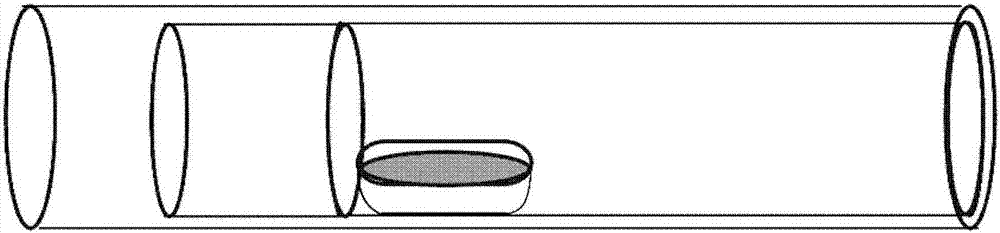

[0025] The closed-tube chemical vapor transport method provided by the present invention grows Ga 2 o 3 The single crystal method involves placing Ga at one end in a closed quartz tube 2 o 3 powder as the source, and the other end is put into the growth Ga 2 o 3 The seed crystal; control the temperature distribution of the source region and the growth region to realize the gas phase transport from the source region to the growth region, and grow Ga 2 o 3 single crystal. The advantages of this method are low growth temperature, fast growth speed, low cost of growth equipment, and good quality of materials.

[0026] In order to increase the vapor pressure of the decomposition product in the quartz tube and accelerate the growth rate, the carbon powder put into the source during the preferred growth process, the amount of carbon powder put into meets: the weight ratio of the carbon put into gallium oxide is 1:100-1:50, more preferably 1:80-1:60.

[0027] Among them, the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com