Preparation method of Nb3O7F nanoarray/graphene heterojunction composite material

A composite material and nanoarray technology, applied in nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve the problems of poor heterojunction uniformity, difficult heterojunction growth, and difficult covalent surface, etc. Conditions are easy to control, good photoelectric performance, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

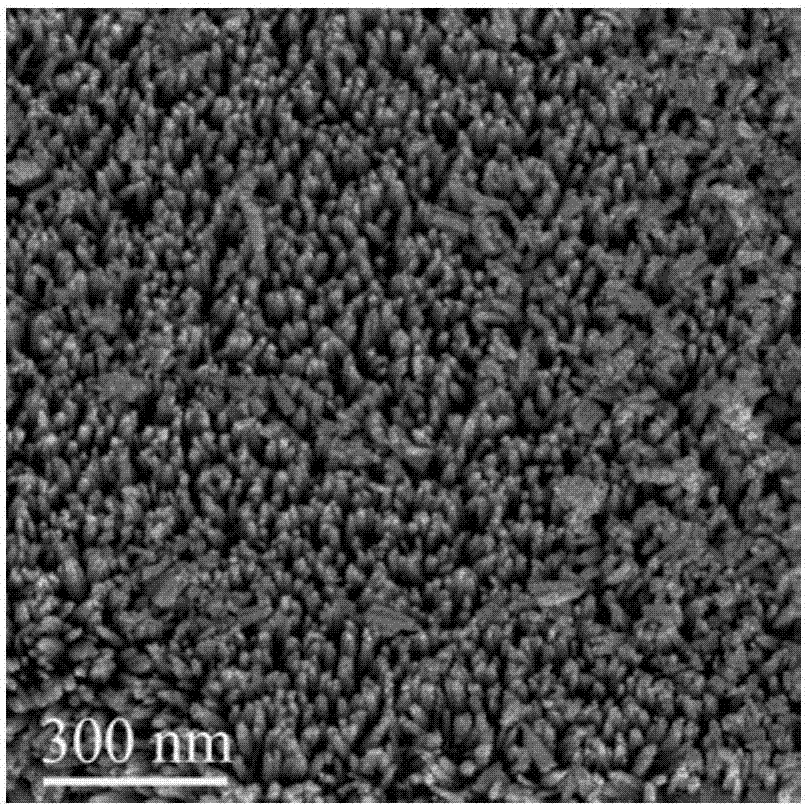

[0060] (1) Weigh 16.9mg graphene and add it to a plastic beaker, add 40mL H 2 O, be mixed with graphene aqueous solution, carry out ultrasonic stripping after stirring, make graphene form uniform dispersion liquid;

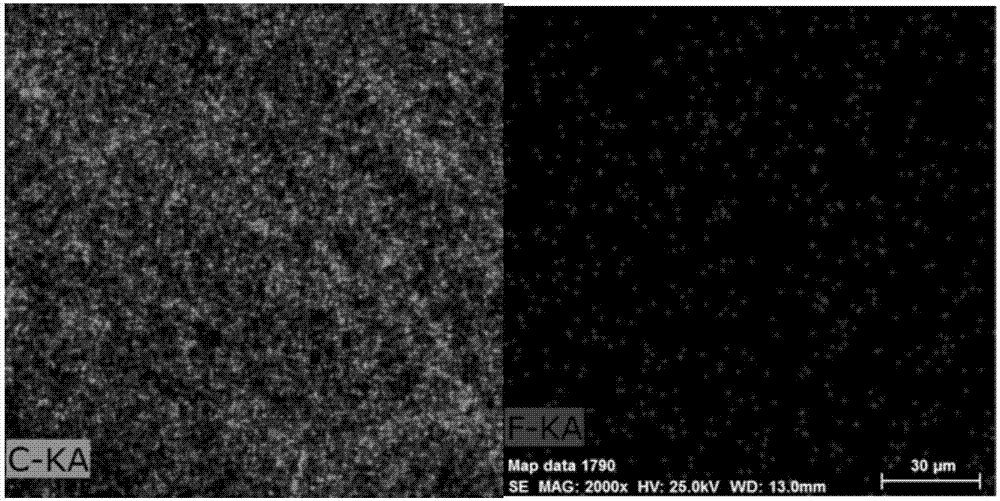

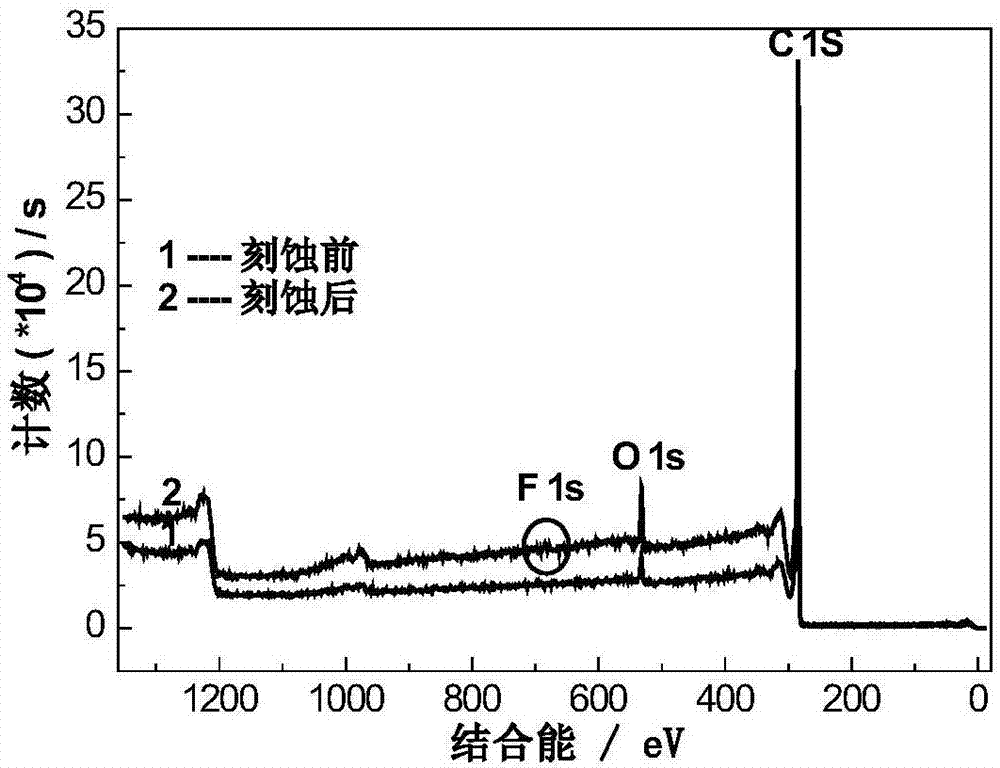

[0061] (2) Then add 0.5mL HF to the above-mentioned dispersion liquid, stir and supplement with ultrasound for 6h, so that the surface of the exfoliated graphene is fully etched to form a carbon-fluorine bond;

[0062] (3) 1.623g NbCl 5 Add to the above solution, stir magnetically for 30min at room temperature, and add 0.65mL HF and 40mL H 2 O, stir for 30s;

[0063] (4) Transfer the above solution to a 100mL polytetrafluoroethylene liner, then put the polytetrafluoroethylene liner into a micro-reactor and seal it; put the reactor into an oven, and heat the reaction at 120°C for 24h , and then cooled with the furnace;

[0064] (5) Centrifuge the precipitate, wash it with normal temperature deionized water for 5 times, and wash it with absolute ethanol for 3 ti...

Embodiment 2

[0067] (1) Weigh 16.9mg of graphene into the beaker, add 40mL of H 2 O, prepared into a graphene aqueous solution, then added 2g of P123, stirred in a water bath at 70°C for 30min, to completely dissolve the P123; then carried out ultrasonic stripping to form a uniform dispersion of graphene;

[0068] (2) Then add 0.5mL HF to the above-mentioned dispersion liquid, stir and supplement with ultrasound for 6h, so that the surface of the exfoliated graphene is fully etched to form a carbon-fluorine bond;

[0069] (3) Weigh 1.623g NbCl 5 Added to the above solution, magnetically stirred at room temperature for 1 h; and added 0.65mL HF and 40mL H 2 O, stir for 30s;

[0070] (4) Transfer the stirred mixed solution to a 100mL polytetrafluoroethylene lining, then put the polytetrafluoroethylene lining into a micro-reactor and seal it well; Heating and reacting for 24h, then cooling with the furnace;

[0071] (5) Centrifuge the precipitate, wash it 5 times with deionized water, and ...

Embodiment 3

[0074] (1) Weigh 16.9mg of graphene into the beaker, add 40mL of H 2 0, be formulated with graphene aqueous solution, add 2g citric acid then, stir 30min in water bath at 70 ℃, make citric acid dissolve completely; Then carry out ultrasonic exfoliation, make graphene form uniform dispersion liquid;

[0075] (2) Then add 0.5mL HF to the above-mentioned dispersion liquid, stir and supplement with ultrasonic 5h, make the graphene surface of exfoliation be fully etched, form carbon-fluorine bond;

[0076] (3) Weigh 1.623g NbCl 5 Added to the above solution, magnetically stirred at room temperature for 1 h; and added 0.65mL HF and 40mL H 2 O, stir for 30s;

[0077] (4) Transfer the stirred mixed solution to a 100mL polytetrafluoroethylene lining, then put the polytetrafluoroethylene lining into a micro-reactor and seal it well; Heating and reacting for 24h, then cooling with the furnace;

[0078] (5) Centrifuge the precipitate, wash it 5 times with deionized water, and wash it ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com