Tin sulfide/gold nanoparticle composite and its preparation method and application

A technology of gold nanoparticles and stannous sulfide, which is applied in the direction of nanotechnology, nanotechnology, metal processing equipment, etc., can solve problems such as inability to orderly assemble gold nanoparticles, and achieve superior performance, environmental friendliness, and high stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

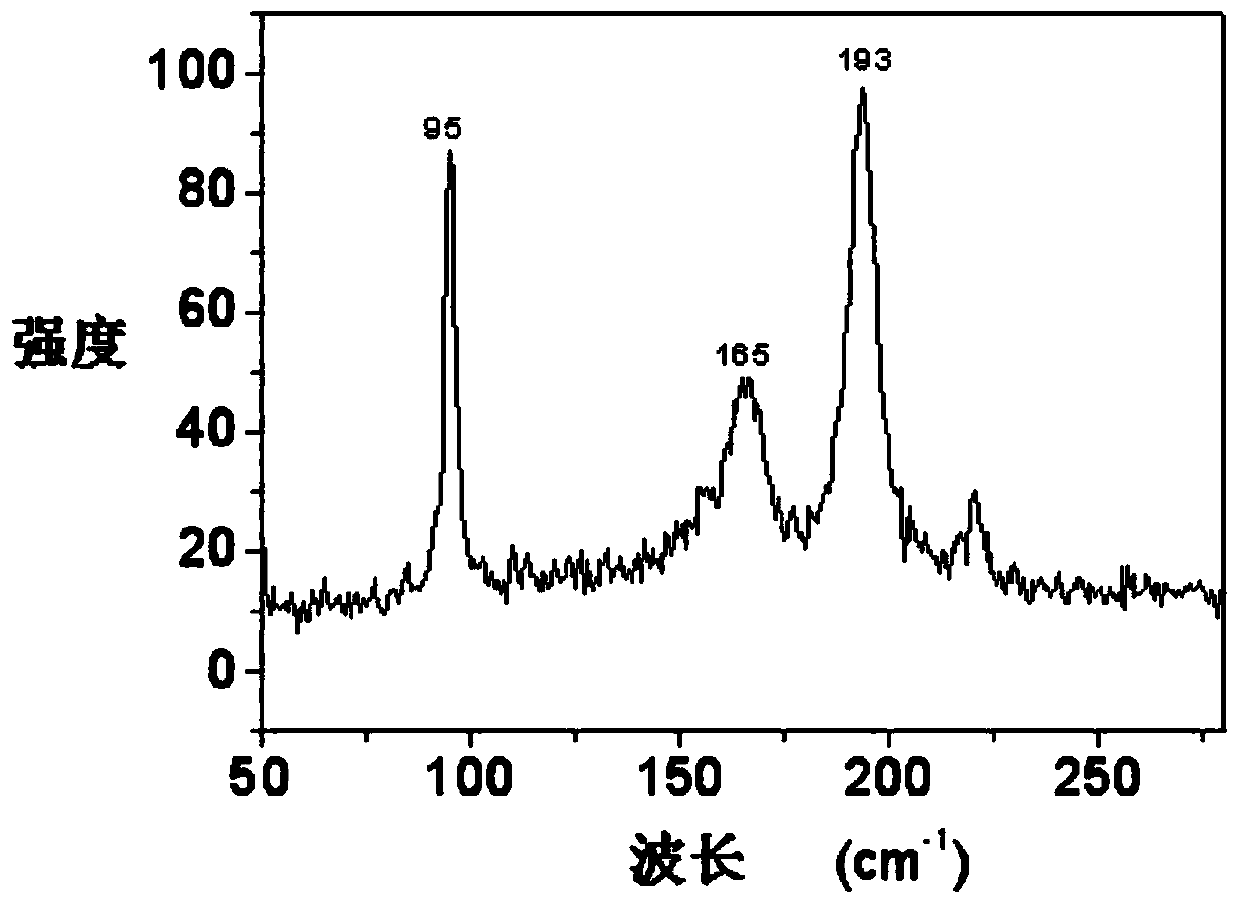

[0020] A self-assembly method for stannous sulfide-induced growth of gold nanoparticles, the steps are as follows:

[0021] (1) Mechanical stripping to obtain stannous sulfide, with a thickness of about 70 nm and a size of a few microns to more than ten microns, annealed in an argon atmosphere for later use;

[0022] (2) Dissolve the chloroauric acid powder in water to obtain a 26% chloroauric acid aqueous solution, drop 2 μm of the chloroauric acid aqueous solution onto the surface of the mechanically stripped stannous sulfide, deposit for 2 min, blow off the excess liquid with nitrogen, Subsequently, the reaction temperature in the oven was 150°C and the reaction time was 5 min;

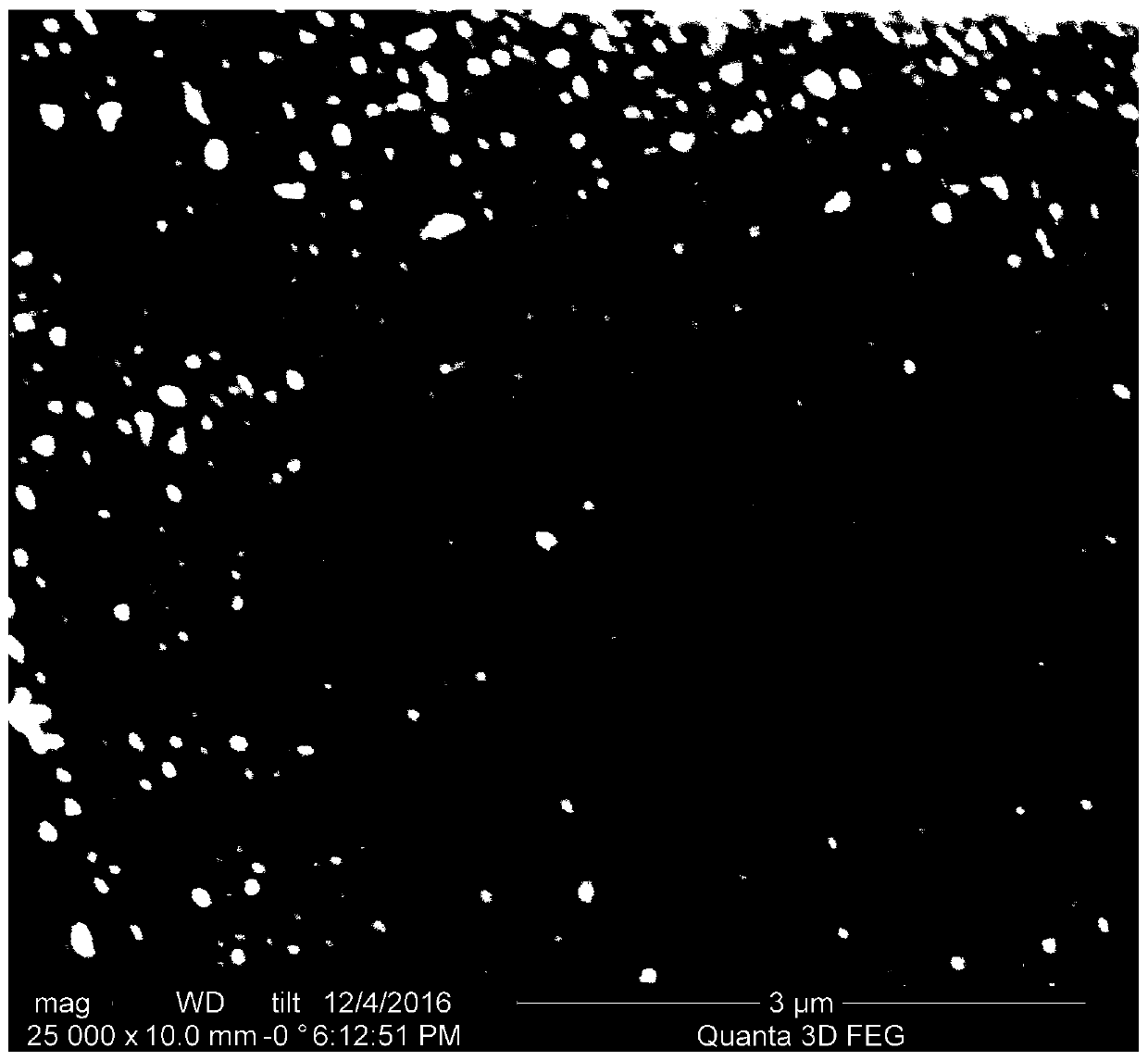

[0023] (3) After the reaction, quickly take out the sample to obtain gold nanoparticles self-assembled in stannous sulfide. The gold nanoparticles are about 15-25 nanometers in size and have good crystallinity.

Embodiment 2

[0025] A self-assembly method for stannous sulfide-induced growth of gold nanoparticles, the steps are as follows:

[0026] (1) The stannous sulfide material is obtained by mechanical stripping, the thickness is about 85 nm, and the size is several microns to more than ten microns, and it is annealed in an argon atmosphere for later use;

[0027] (2) Dissolve the chloroauric acid powder in water, dilute it to obtain a 13% chloroauric acid aqueous solution, drop 3 μm of chloroauric acid aqueous solution onto the surface of the mechanically stripped stannous sulfide, deposit for 3 minutes, and blow off the excess liquid with nitrogen gas , and then the reaction temperature in the oven was 120°C and the reaction time was 5 min;

[0028] (3) After the reaction, quickly take out the sample to obtain gold nanoparticles self-assembled in stannous sulfide. The gold nanoparticles are about 10-15 nanometers in size and have good crystallinity.

Embodiment 3

[0030] A self-assembly method for stannous sulfide-induced growth of gold nanoparticles, the steps are as follows:

[0031] (1) The stannous sulfide material is obtained by mechanical stripping, the thickness is about 100 nm, and the size is several microns to more than ten microns, and it is annealed in an argon atmosphere for later use;

[0032] (2) Dissolve the chloroauric acid powder in water, dilute it to obtain a 19% chloroauric acid aqueous solution, drop 2 μm of the chloroauric acid aqueous solution onto the surface of the mechanically stripped stannous sulfide, deposit for 4 minutes, and blow off the excess liquid with nitrogen gas , and then the reaction temperature in the oven was 130°C and the reaction time was 3 min;

[0033] (3) After the reaction, quickly take out the sample to obtain gold nanoparticles self-assembled in stannous sulfide. The gold nanoparticles are about 8-12 nanometers and have good crystallinity.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com