Methacrylic resin modified polyurethane waterproof coating for concrete bridge deck of railway ballast track bridge and preparation method thereof

A methacrylic acid and polyurethane waterproofing technology, used in polyurea/polyurethane coatings, coatings, etc., can solve problems such as hydrolysis resistance, fire hazard, and moisture inability to construct, and achieve excellent aging resistance and excellent tensile strength. Strength, improve the effect of film compaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

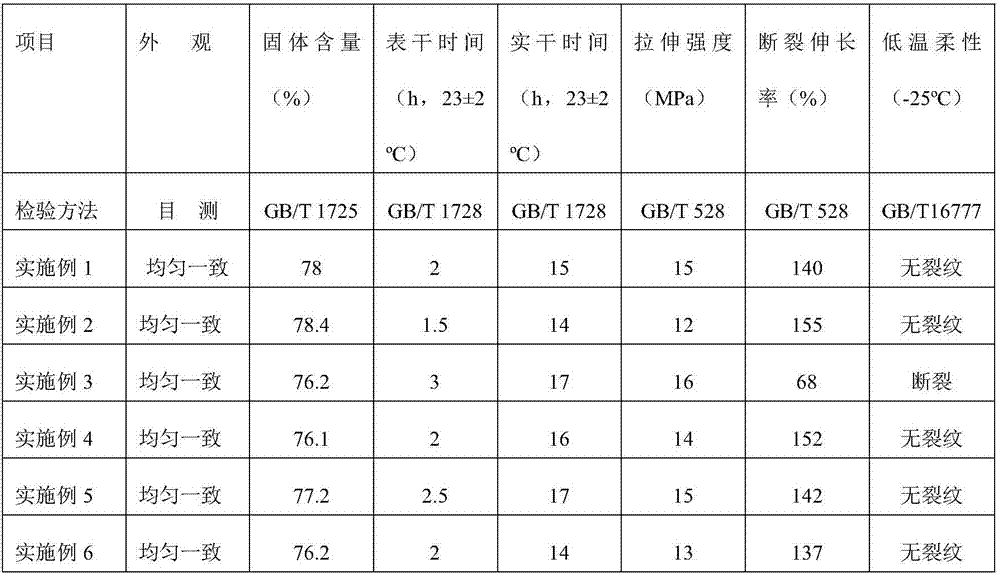

Examples

Embodiment 1

[0036] The present invention uses methacrylic acid resin modified polyurethane waterproof coating for the concrete bridge deck of railway ballasted track bridge, which is formed by mixing component A and component B according to the mass ratio of 100:20:

[0037] Group A allocation ratio:

[0038]40 parts of hydroxymethacrylic resin (hydroxyl value: 60-70mgKOH / g)

[0039] Active methacrylic resin 40 parts

[0040] 0.5 parts of N,N-dimethyl-p-toluidine

[0041] 15 parts of rutile titanium dioxide (CR828)

[0042] Medium pigment carbon black (MA100) 0.05 parts

[0043] Anti-sedimentation additive (organic bentonite MP250) 1 part

[0044] Wetting and dispersing agent (DISPERBYK 110) 0.8 parts

[0045] Ultraviolet light absorber (UV327) 0.5 part

[0046] Light stabilizer (GW508) 0.5 parts

[0047] Ultrafine barium sulfate powder (6000 mesh) 15 parts

[0048] Defoamer (BYK 066N) 0.8 parts

[0049] Group B distribution ratio:

[0050] 15 parts of butyl acetate, 10 parts of...

Embodiment 2

[0060] The present invention uses methacrylic acid resin modified polyurethane waterproof coating for the concrete bridge deck of railway ballasted track bridge, which is formed by mixing component A and component B according to the mass ratio of 100:20:

[0061] Group A allocation ratio:

[0062] 40 parts of hydroxymethacrylic resin (hydroxyl value: 60-70mgKOH / g)

[0063] 60 parts of active methacrylic resin

[0064] 0.75 parts of N,N-dimethyl-p-toluidine

[0065] 15 parts of rutile titanium dioxide (CR828)

[0066] Medium pigment carbon black (MA100) 0.05 parts

[0067] Anti-sedimentation additive (organic bentonite MP250) 1 part

[0068] Wetting and dispersing agent (DISPERBYK 110) 0.8 parts

[0069] Ultraviolet light absorber (UV327) 0.5 part

[0070] Light stabilizer (GW508) 0.5 parts

[0071] Ultrafine barium sulfate powder (6000 mesh) 15 parts

[0072] Defoamer (BYK 066N) 0.8 parts

[0073] Group B distribution ratio:

[0074] 12.5 parts of butyl acetate,

[...

Embodiment 3

[0085] The present invention uses methacrylic acid resin modified polyurethane waterproof coating for the concrete bridge deck of railway ballasted track bridge, which is formed by mixing component A and component B according to the mass ratio of 100:20:

[0086] Group A allocation ratio:

[0087] 40 parts of hydroxymethacrylic resin (hydroxyl value: 60-70mgKOH / g)

[0088] Active methacrylic resin 20 parts

[0089] 0.25 parts of N,N-dimethyl-p-toluidine

[0090] 15 parts of rutile titanium dioxide (CR828)

[0091] Medium pigment carbon black (MA100) 0.05 parts

[0092] Anti-sedimentation additive (organic bentonite MP250) 1 part

[0093] Wetting and dispersing agent (DISPERBYK 110) 0.8 parts

[0094] Ultraviolet light absorber (UV327) 0.5 part

[0095] Light stabilizer (GW508) 0.5 parts

[0096] Ultrafine barium sulfate powder (6000 mesh) 15 parts

[0097] Defoamer (BYK 066N) 0.8 parts

[0098] Group B distribution ratio:

[0099] 10.3 parts of butyl acetate,

[010...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hydroxyl value | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com