Sulfonate anionic-nonionic surfactant for oilfield oil driving and preparation method thereof

A surfactant, non-ionic surface technology, applied in chemical instruments and methods, drilling compositions, organic chemistry, etc., can solve problems such as difficulty in industrialization, corrosion of equipment, environmental pollution, etc., to achieve less environmental pollution, reaction Gentle, high-conversion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

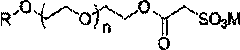

[0022] A kind of sulfonate anion nonionic surfactant that is used for oil field flooding, the general structural formula of described sulfonate anion nonionic surfactant is:

[0023]

[0024] Among them, the R group is C 12 Alkyl, n=5; M is ammonium ion (NH 4 + ).

[0025] The preparation reaction formula of this tensio-active agent is as follows:

[0026]

[0027] The preparation method mainly includes the following steps: Step 1) Add nonionic surfactant a and acrylic acid b into the reactor at a molar ratio of 1:1.2, and add 20% of strong acidic ions relative to the mass of nonionic surfactant a The exchange resin is used as a catalyst to synthesize a nonionic surfactant c with a double bond in the end group; step 2) mix 1 mole of the aqueous solution of the nonionic surfactant c with a double bond in the end group obtained in step 1) with 1.1 mol of After ammonium sulfite was stirred at 30°C for 20 hours, the water was distilled off, and the crude product was extr...

Embodiment 2

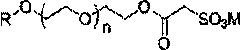

[0029] A kind of sulfonate anion nonionic surfactant that is used for oil field flooding, the general structural formula of described sulfonate anion nonionic surfactant is:

[0030]

[0031] Among them, the R group is C 13 Alkyl group, n=8; M is ammonium ion (NH 4 + ).

[0032] The preparation reaction formula of this tensio-active agent is as follows:

[0033]

[0034] The preparation method mainly includes the following steps: Step 1) Add nonionic surfactant a and acrylic acid b into the reactor at a molar ratio of 1:1.5, and add 15% of strong acidic ions relative to the mass of nonionic surfactant a The exchange resin is used as a catalyst to synthesize a nonionic surfactant c with a double bond in the end group; step 2) mix 1 mole of the aqueous solution of the nonionic surfactant c with a double bond in the end group obtained in step 1) with 1.2 mol of After ammonium bisulfite was stirred at 25°C for 21 hours, the water was distilled off, and the crude product ...

Embodiment 3

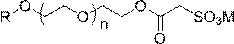

[0036] A kind of sulfonate anion nonionic surfactant that is used for oil field flooding, the general structural formula of described sulfonate anion nonionic surfactant is:

[0037]

[0038] Among them, the R group is C 14 Alkyl group, n=10; M is sodium ion (Na + ).

[0039] The preparation reaction formula of this tensio-active agent is as follows:

[0040]

[0041] The preparation method mainly includes the following steps: step 1) adding nonionic surfactant a and acrylic acid b into the reactor at a molar ratio of 1:1.8, and adding 25% of strong acidic ions relative to the mass of nonionic surfactant a The exchange resin is used as a catalyst to synthesize a nonionic surfactant c with a double bond in the end group; step 2) mix 1 mole of the aqueous solution of the nonionic surfactant c with a double bond in the end group obtained in step 1) with 1.4 mol of After sodium sulfite was stirred at 60°C for 18 hours, the water was distilled off, and the crude product wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com