Binder resin for lithium secondary battery electrode, electrode for lithium secondary battery, and lithium secondary battery

A binder resin and lithium secondary battery technology, applied in battery electrodes, non-aqueous electrolyte battery electrodes, lithium batteries, etc., can solve problems such as insufficient characteristics, achieve excellent charge and discharge efficiency and safety, and high specific capacity , The effect of improving output characteristics and life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

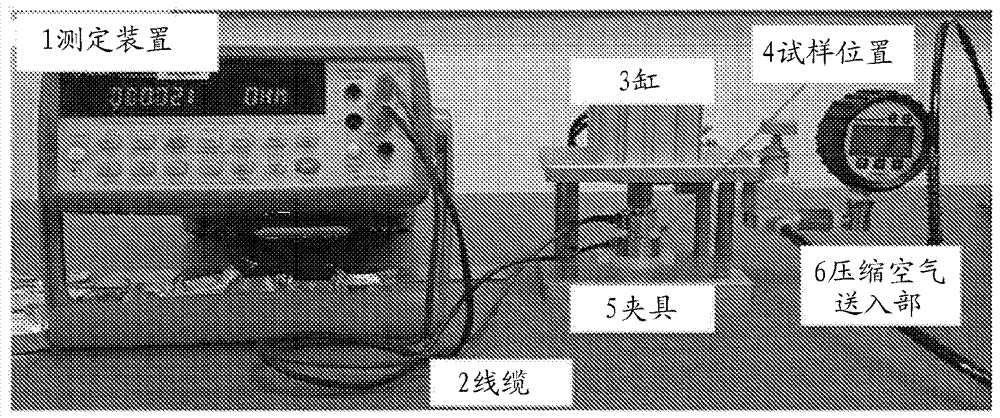

Image

Examples

Embodiment 1

[0113] A stirrer, a nitrogen gas introduction tube, and a cooling tube equipped with a moisture receiver were attached to a glass-made three-neck separable flask. Throw in 58.84g (0.2 mole) of 3,4,3',4'-biphenyltetracarboxylic dianhydride, 15.21g (0.1 mole) of 1,3-diaminobenzoic acid (carboxyl-containing aromatic diamine; general formula [ Ar in II] 1 Components), valerolactone 1.5g (0.015 mol), pyridine 2.4g (0.03 mol), NMP 200g, toluene 30g, at room temperature, under nitrogen atmosphere, after stirring at 200rpm for 30 minutes, the temperature was raised to 180°C, and heated and stirred for 1 hour. After removing 15ml of the azeotropic component of toluene-water, after air cooling, add 46.53g (0.15mol) of 4,4'-oxydiphthalic dianhydride, 73.0g of 1,3-bis(3-aminophenoxy)benzene g (0.25 mole) (aromatic diamine containing aromatic ether bond; Ar in general formula [III] 2 Component), NMP360g, toluene 90g, after stirring at room temperature for 30 minutes, the temperature was ...

Embodiment 2

[0115] The same apparatus as in Synthesis Example 1 was used. Add 58.84 g (0.2 mol) of 3,4,3',4'-biphenyltetracarboxylic dianhydride, 5-amino-1-(4'-aminophenyl)-1,3,3-trimethylindane 26.38g (0.1 mol) (aromatic diamine containing phenylindane structure; Ar in general formula [IV] 3 Components), valerolactone 1.5g (0.015 mol), pyridine 2.4g (0.03 mol), NMP 200g, toluene 30g, at room temperature, under nitrogen atmosphere, after stirring at 200rpm for 30 minutes, the temperature was raised to 180°C, and heated and stirred for 1 hour. After removing 15ml of the azeotropic component of water-toluene and air cooling, add 46.53g (0.15mol) of 4,4'-oxydiphthalic dianhydride and 73.0g of 1,3-bis(3-aminophenoxy)benzene g (0.25 mole) (aromatic diamine containing aromatic ether bond; Ar in general formula [III] 2 Component), NMP360g, toluene 90g, after stirring at room temperature for 30 minutes, the temperature was raised to 180° C., and heated and stirred for 1 hour. After removing 45...

Embodiment 3

[0127] The mass of the polyimide solution used in Example 1 was 75 g (polyimide solid content: 15g), and the negative electrode was produced by the method similar to Example 1 except that.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com