Surface modification method for improving electrochemical performance of lithium-rich material, obtained lithium-rich material and application thereof

A lithium-rich material and surface modification technology, which is applied in the field of new energy electrode materials, can solve problems such as destroying the material structure, and achieve the effect of excellent electrochemical performance of the material, simple method, and large output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] 1) Mix 0.5g lithium-rich material powder with 0.5g 2-methylimidazole.

[0032] 2) Put the above mixture under vacuum condition, heat it to 150°C, keep it warm for 8h, cool it naturally to room temperature and take it out.

[0033] 3) put the product obtained in the previous step in the tube furnace N 2 Or in an Ar atmosphere at 450°C for 2h, with a heating rate of 5°C / min, and take it out after natural cooling to room temperature, to obtain a carbon & nickel-cobalt alloy quantum dot heterostructure-coated lithium-rich material.

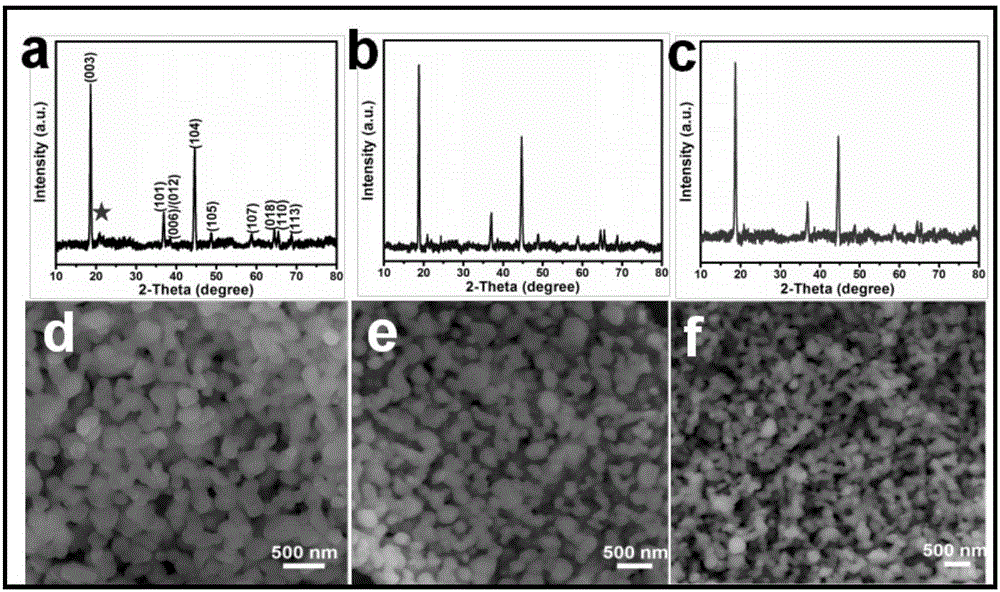

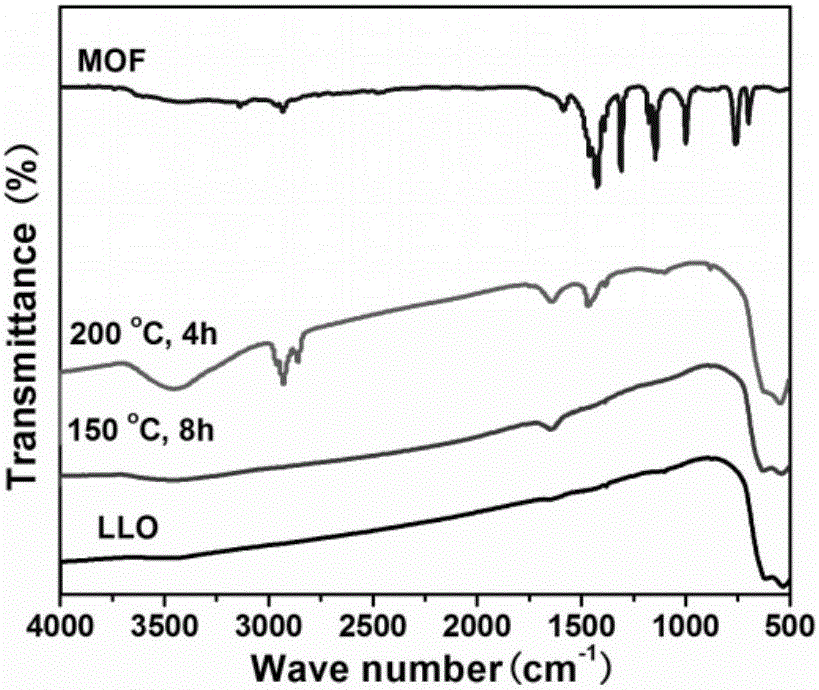

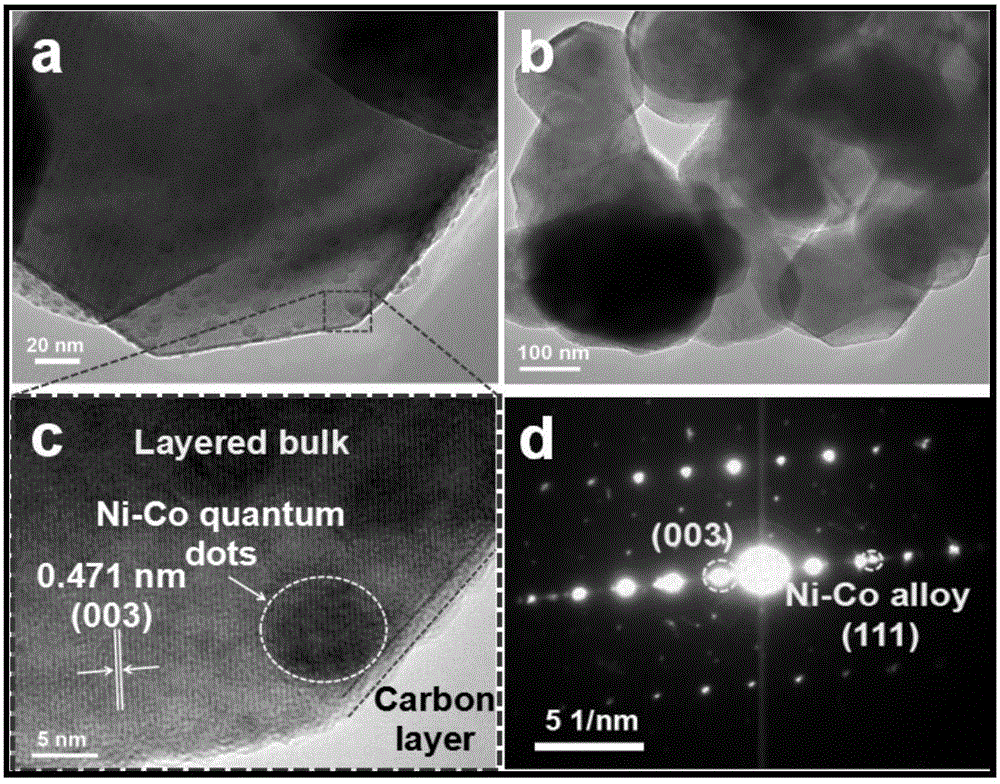

[0034] Taking the carbon & nickel-cobalt alloy quantum dot heterostructure-coated lithium-rich material produced in this example as an example, its structure was confirmed by X-ray diffractometer and scanning electron microscope. Such as figure 1 As shown in (a), the X-ray diffraction pattern (XRD) shows that the product is α-NaFeO 2 Structure, O3-type layered compound, without any heterogeneous phase. Scanning electron microscope (SEM) ima...

Embodiment 2

[0045] 1) Mix 0.5g of lithium-rich material powder with 1g of 2-methylimidazole.

[0046] 2) Put the above mixture under vacuum condition, heat it to 160°C, keep it warm for 8h, cool it down to room temperature naturally, and take it out.

[0047] 3) put the product obtained in the previous step in the tube furnace N 2 Or in an Ar atmosphere at 450°C for 2h, with a heating rate of 4°C / min, take it out after natural cooling to room temperature, and you can get a carbon & nickel-cobalt alloy quantum dot heterostructure-coated lithium-rich material.

[0048] When the lithium-rich material modified by this method is used as the positive electrode material of lithium ion battery, after 100 cycles at a current density of 0.4C, it still has 210mAh g -1 The reversible specific capacity, the capacity retention rate can reach 78%; cycle at a current density of 2C, after 300 cycles, the reversible specific capacity reaches 112.6mAh g -1 , the capacity retention rate can reach 85%, and ...

Embodiment 3

[0050] 1) Mix 0.5g lithium-rich material powder with 0.5g methylimidazole.

[0051] 2) Put the above mixture under vacuum condition, heat it to 180°C, keep it warm for 4h, cool it down to room temperature naturally, and take it out.

[0052] 3) put the product obtained in the previous step in the tube furnace N 2 Or in an Ar atmosphere at 480°C for 3 hours, with a heating rate of 3°C / min, and then take it out after natural cooling to room temperature, to obtain a carbon & nickel-cobalt alloy quantum dot heterostructure-coated lithium-rich material.

[0053] When the lithium-rich material modified by this method is used as the positive electrode material of lithium ion battery, after 100 cycles at a current density of 0.4C, it still has 200mAh g -1 The reversible specific capacity, the capacity retention rate can reach 76%; cycled at a current density of 2C, after 300 cycles, the reversible specific capacity can reach 110mAh g -1 , the capacity retention rate can reach 85%, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com