Method for preparing mesopore type active carbon from amygdalus pedunculata shells

A long-handled almond shell and activated carbon technology, applied in chemical instruments and methods, carbon compounds, inorganic chemistry, etc., can solve the problems of high compactness and limitations, and achieve the effects of low production cost, large industrialization potential, and easy industrial production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

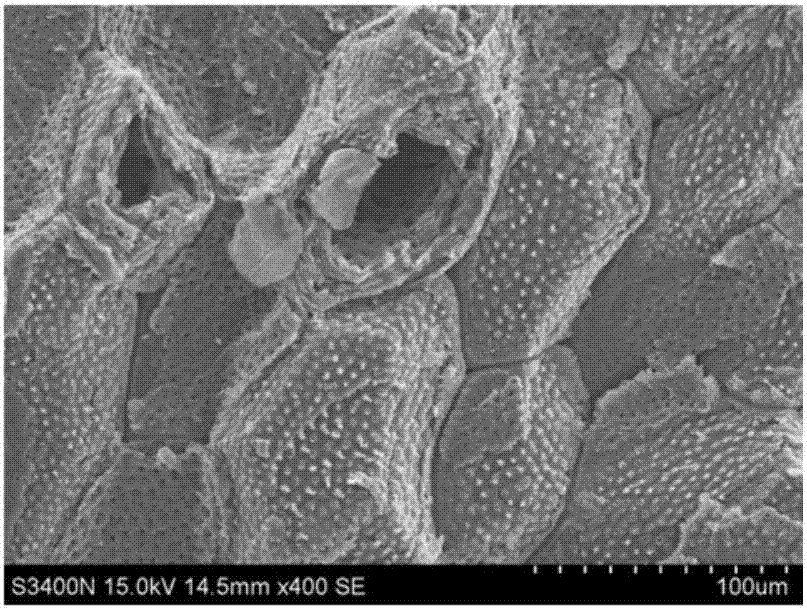

[0022] 1. Weigh 50g of pretreated almond shells, raise the temperature to 600°C at a rate of 10°C / min under a nitrogen flow rate of 60mL / min, keep it warm for 1h, and then cool it down to room temperature naturally. The yield is 32%.

[0023] 2. Weigh 10g of long handle almond shell charring material, raise the temperature to 800°C at a rate of 10°C / min under the condition of nitrogen flow rate of 60mL / min, according to the ratio of charring material to water vapor mass ratio of 1:6 It was activated by steam for 30 minutes, and then cooled to room temperature in a nitrogen atmosphere. The yield was 38%.

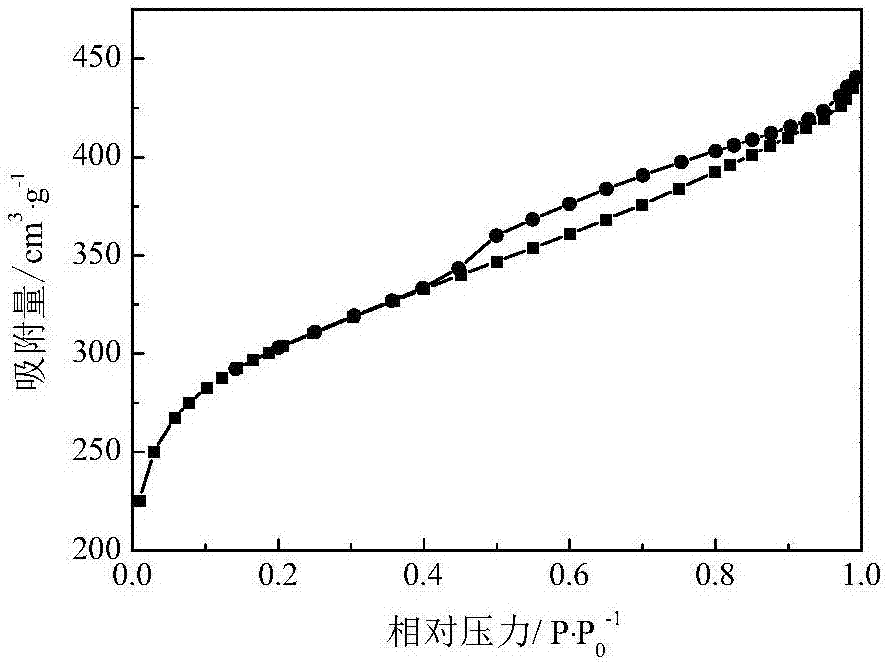

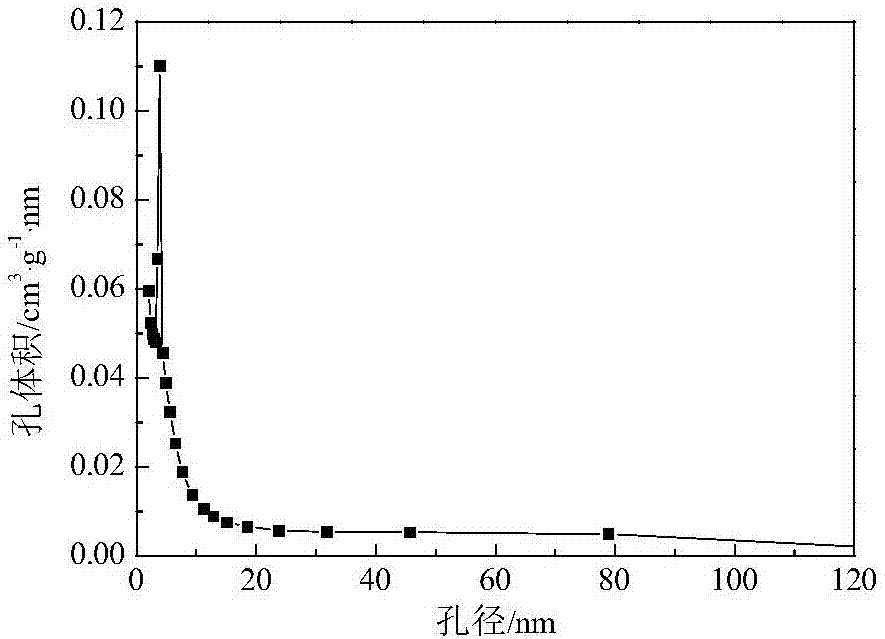

[0024] 3. After the activated product was washed with water, pickled, washed with water, dried and pulverized, its iodine adsorption value was determined to be 1000mg / g, methylene blue adsorption value was 255mg / g, and the specific surface area was 1100m 2 / g, the mesoporosity is 68%.

Embodiment 2

[0026] In this embodiment, the activation temperature is raised to 850°C, and the rest are the same as in Example 1. The yield of activated carbon obtained is 36%, the iodine adsorption value is 1227mg / g, the methylene blue adsorption value is 300mg / g, and the specific surface area is 1356m 2 / g, mesoporosity is 72%.

Embodiment 3

[0028] In this embodiment, the activation temperature is raised to 900°C, and the rest are the same as in Example 1. The yield of activated carbon obtained is 30%, the adsorption value of iodine is 1289mg / g, the adsorption value of methylene blue is 345mg / g, and the specific surface area is 1374m 2 / g, mesoporosity is 80%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| iodine adsorption value | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com