Method for synthesizing glyoxylate through oxidation of glycollate

A glycolic acid ester and glyoxylic acid ester technology is applied in chemical instruments and methods, preparation of organic compounds, preparation of carboxylic acid esters, etc., which can solve the problems of low selectivity of glyoxylic acid esters and achieve the effect of improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

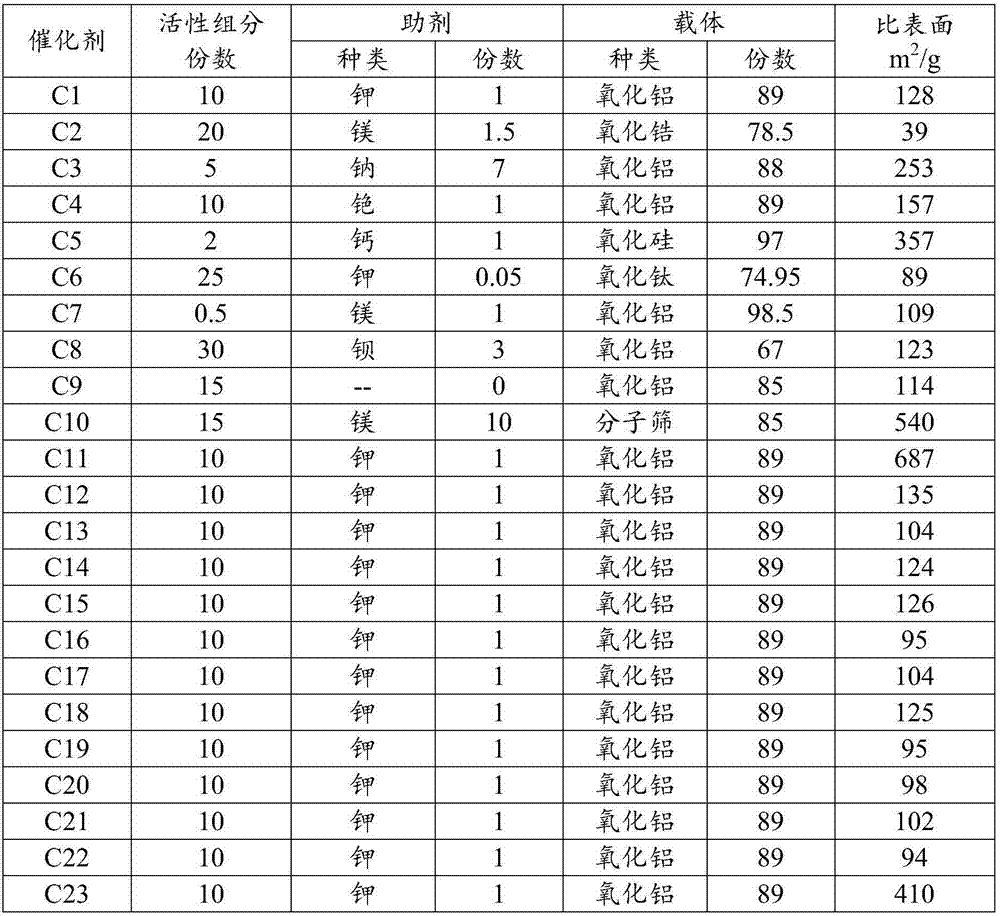

Embodiment 1

[0030] Prepare 200ml of ferric nitrate solution I containing 5.6% iron and stir, and the specific surface of 100g is 105m 2 / g alumina carrier was added to solution I and stirred evenly to obtain slurry II, and then ammonia water was added dropwise to slurry II under stirring, and the pH at the end point was controlled to be 8 to obtain slurry IV, and the product was taken out after aging at 80°C for 5 hours Filter, wash the filter cake with ethanol and deionized water, and dry at 120°C. Then prepare 50ml of potassium nitrate solution containing 2.3% potassium, impregnate and dry the filter cake, dry at 120°C, and roast at 500°C to obtain catalyst C1, take catalyst samples for X-fluorescence (XRF) determination of catalyst components, and specific surface BET characterization Test, the test results are shown in Table 1.

Embodiment 2

[0032] Prepare 200ml solution I of ferric nitrate containing 12.8% iron according to the method of [Example 1] and stir, and the specific surface of 100g is 20m 2 / g zirconia carrier was added to solution I and stirred evenly to obtain slurry II, and then ammonia water was added dropwise to slurry II under stirring, and the pH at the end point was controlled to be 8 to obtain slurry IV, which was aged at 80°C for 5 hours and then taken out The product was filtered, and the filter cake was washed with ethanol and deionized water, and dried at 120°C. Then prepare 40ml of magnesium nitrate solution containing 4.8% magnesium, impregnate and dry the filter cake, dry at 120°C, and roast at 500°C to obtain catalyst C2. The catalyst samples are taken for cesium XRF and BET characterization tests. The test results are shown in Table 1.

Embodiment 3

[0034] Prepare 200ml solution I of ferric nitrate containing 2.9% iron according to the method of [Example 1] and stir, and the specific surface of 100g is 250m 2 / g alumina carrier was added to solution I and stirred evenly to obtain slurry II, and then ammonia water was added dropwise to slurry II under stirring, and the pH at the end point was controlled to be 8 to obtain slurry IV, which was aged at 80°C for 5 hours and then taken out The product was filtered, and the filter cake was washed with ethanol and deionized water, and dried at 120°C. Then prepare 50ml of sodium nitrate solution containing 15.9% sodium, impregnate and dry the filter cake, dry at 120°C, and roast at 500°C to obtain catalyst C3. The catalyst samples were taken for XRF and BET characterization tests. The test results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com