Preparation method of titanium dioxide for powder coating

A titanium dioxide and powder coating technology, applied in powder coatings, chemical instruments and methods, coatings, etc., can solve the problem of no powder coating strength and toughness optimization, no finished powder coating adhesion improvement, organic modifier and titanium dioxide combination. It can improve the coating effect, improve the coating efficiency, and improve the oil dispersion effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

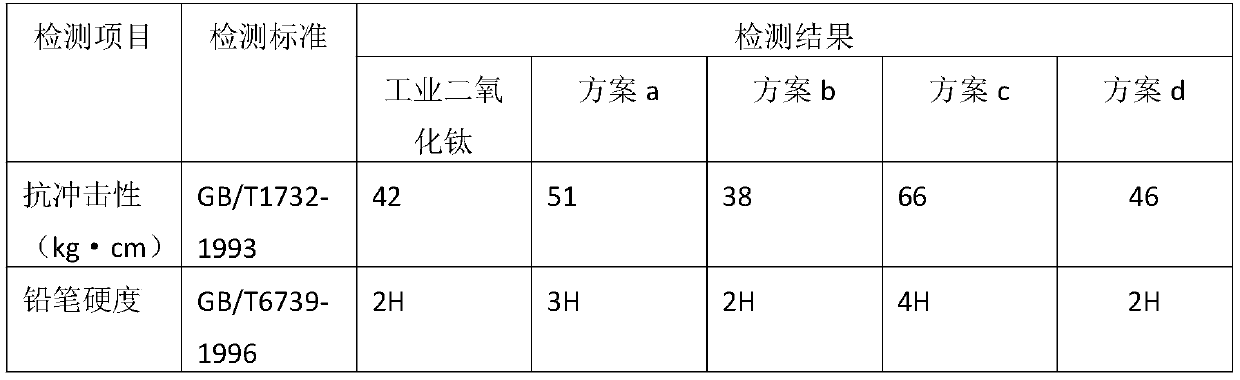

[0045] Those skilled in the art know that the coating film hardness of powder coatings, impact resistance and other indicators are key indicators for evaluating the quality of powder coatings, and as a commonly used additive in powder coatings, the mechanical properties of titanium dioxide will also have a negative impact on the finished product of powder coatings. big impact. Therefore, in the prior art, the surface of titanium dioxide is often coated with an inorganic layer to increase its mechanical properties.

[0046] Porous titanium dioxide particles can increase its specific surface area and improve dispersion, but it will affect the hardness of titanium dioxide particles. However, it is unexpectedly found in the present invention that porous titanium dioxide has better mechanical properties after inorganic coating.

[0047] Specifically, the operation steps are:

[0048] Scheme a is to only carry out inorganic coating on titanium dioxide. The specific steps are: take...

experiment example 2

[0060] Those skilled in the art know that, in the presence of an initiator, the polymerization of polyacrylic acid can be initiated by ultraviolet light provided by a high-pressure mercury lamp, thereby causing the curing of the polyacrylic acid-containing material.

[0061] However, when coating titanium dioxide, those skilled in the art do not want polyacrylic acid to polymerize, or only hope that polyacrylic acid polymerizes to a small extent, so as to ensure that the surface coating of titanium dioxide will not be affected. Therefore, when polyacrylic acid coats titanium dioxide, those skilled in the art generally would not think of introducing ultraviolet light.

[0062] On the other hand, those skilled in the art know that microwaves of appropriate power can heat the particles and at the same time promote the solid-phase deposition of gas molecules on the surface of the particles.

[0063] However, the present inventors unexpectedly found in experiments that when titaniu...

Embodiment 1

[0084] (1) Take industrial titanium dioxide, and use a centrifugal classifier for nano-scale particle classification to screen the titanium dioxide particles to a size between 50nm and 10μm.

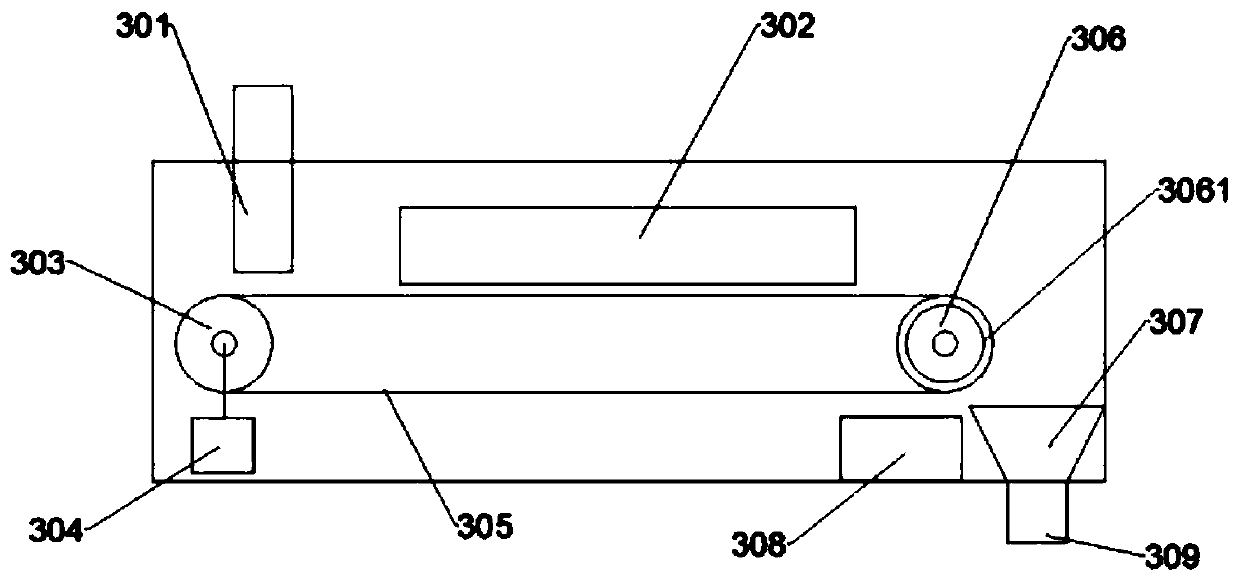

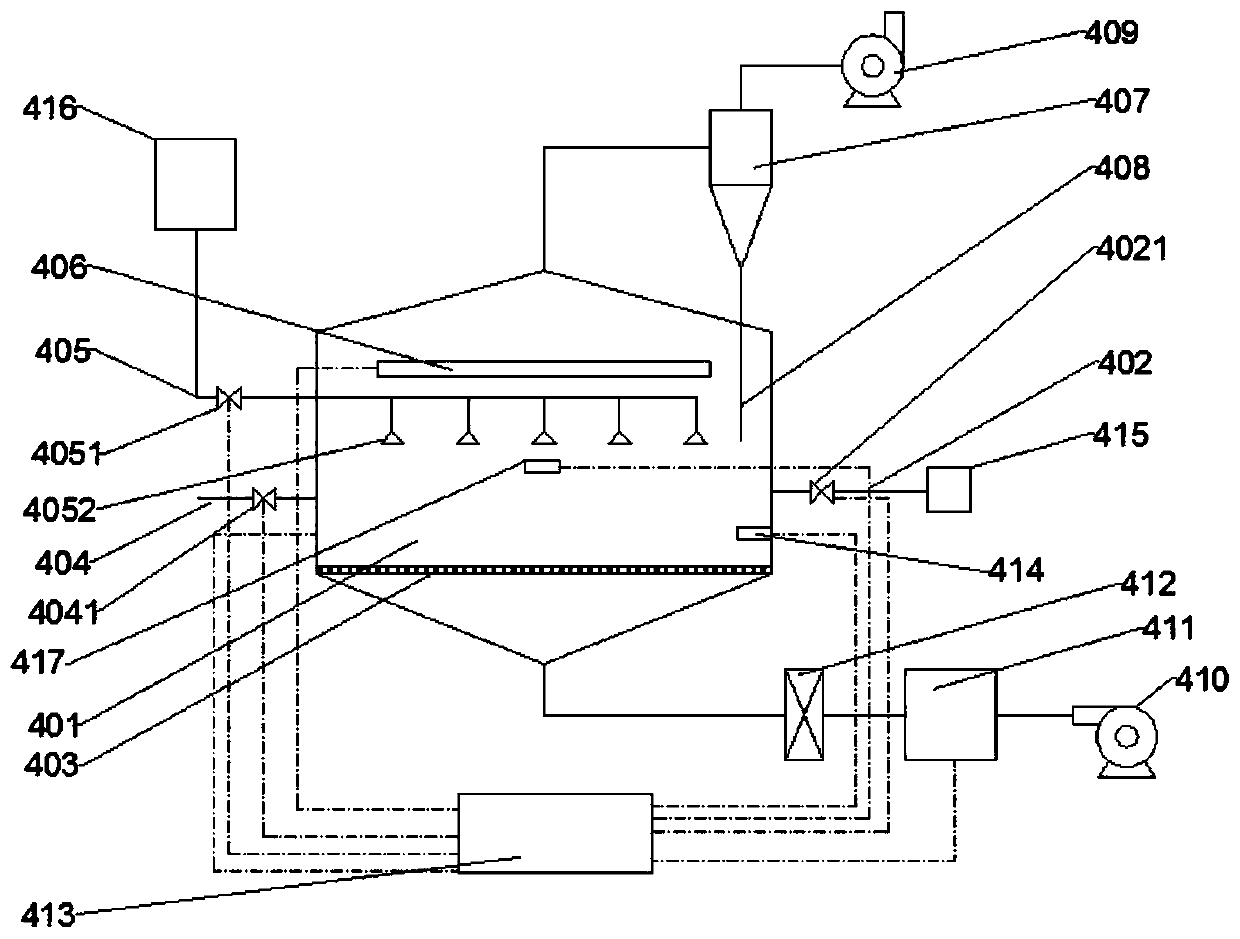

[0085] (2) the titanium dioxide that step (1) obtains is added such as figure 1 As shown, the iron removal is carried out in the iron removal device equipped with a permanent magnet iron remover. The iron removal device includes: a feed pipe for iron removal, which is arranged on the shell of the iron removal device and extends to the inside of the iron removal device; a transmission mechanism, which includes a driving device, a driving roller, and a driven roller 1. Conveyor belt, the driving device is connected with the driving roller or the driven roller to provide power for the transmission mechanism, the driving roller and the driven roller are connected by a conveyor belt, and a permanent magnet is arranged on the axially outer edge of the driven roller The permanent magnetic slee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| cure temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com