Biodegradable regenerated polyester and preparation method thereof

A recycled polyester and biological technology, applied in the fields of biodegradable recycled polyester and its preparation, high-quality biodegradable recycled polyester and its high-efficiency preparation, can solve the problem of high TVOC content in biodegradable recycled polyester, and achieve It is convenient for precise control, saves production cost and ensures the effect of uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

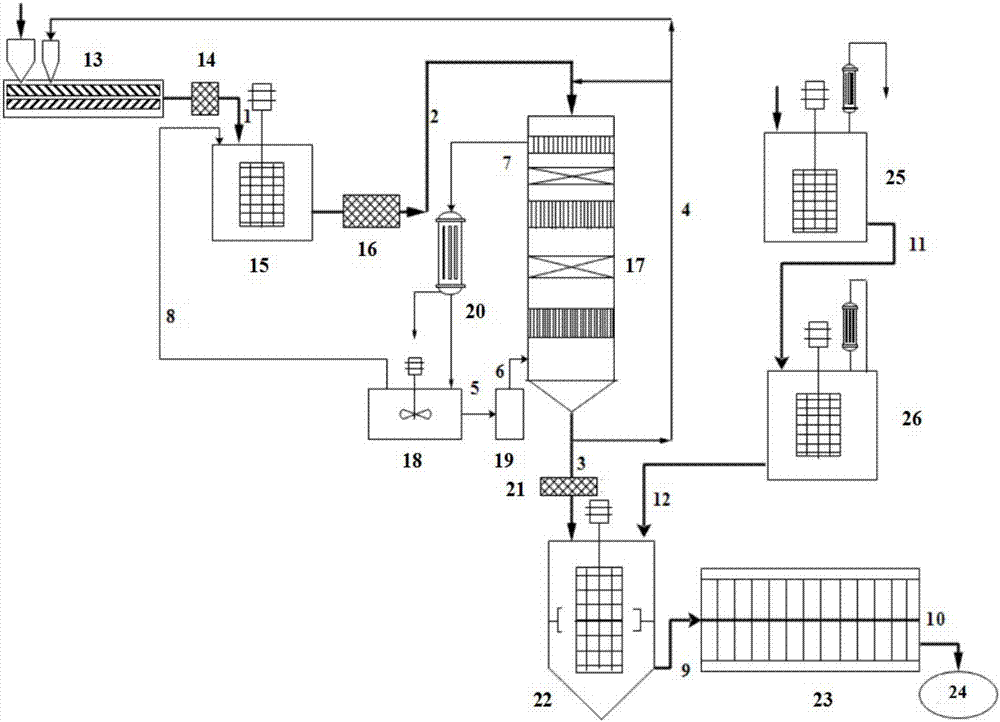

[0062] A preparation method of biodegradable regenerated polyester, such as figure 1 shown, the steps are as follows:

[0063] 1) Under the protection of nitrogen, the polyester recycle material with a moisture content of 95 ppm, a catalyst and a polyester oligomer melt with an average degree of polymerization of 1.5 were added to the twin-screw extruder 13 for reactive melt blending to obtain an average polymerization. The initial depolymerization melt with a degree of 20, wherein the mass ratio of polyester recycled material and polyester oligomer melt is 0.1:1, the catalyst is tetra-n-butyl titanate, and the mass of metal elements in the catalyst is relative to the mass of the polymer. According to the mass calculation of the ester oligomer melt, the content of the catalyst is 10 ppm; the reaction conditions are: the temperature of the twin-screw feeding section is 260 °C, the temperature of the twin-screw compression section is 275 °C, the temperature of the homogenization...

Embodiment 2

[0076] A preparation method of biodegradable regenerated polyester, the steps are as follows:

[0077] 1) Under the protection of nitrogen, the polyester recycled material with a moisture content of 92 ppm, a catalyst and a polyester oligomer melt with an average degree of polymerization of 2.8 were added to a twin-screw extruder for reactive melt blending to obtain an average degree of polymerization. It is the preliminary depolymerization melt of 31, wherein the mass ratio of polyester recycled material and polyester oligomer melt is 1.3:1, the catalyst is tetraisopropyl titanate, and the mass of metal elements in the catalyst is relative to the polyester The mass of the oligomer melt was calculated, and the content of the catalyst was 30 ppm; the reaction conditions were: the temperature of the twin-screw feeding section was 261 °C, the temperature of the twin-screw compression section was 277 °C, and the temperature of the homogenization section was 276 °C, and the time was...

Embodiment 3

[0087] A preparation method of biodegradable regenerated polyester, the steps are as follows:

[0088] 1) Under the protection of nitrogen, polyester recycled material with a moisture content of 91.5 ppm, a catalyst and a polyester oligomer melt with an average degree of polymerization of 2.0 were added to a twin-screw extruder for reactive melt blending to obtain an average The preliminary depolymerization melt with a degree of polymerization of 32, wherein the mass ratio of the polyester recycled material to the polyester oligomer melt is 1.5:1, the catalyst is ethylene glycol titanium, and the mass of the metal elements in the catalyst is relative to the polyester The mass of the oligomer melt was calculated, and the content of the catalyst was 50 ppm; the reaction conditions were: the temperature of the twin-screw feeding section was 262 °C, the temperature of the twin-screw compression section was 278 °C, and the temperature of the homogenization section was 278 °C, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com