Low-density PVC pipe added with polyurethane and preparation method of PVC pipe

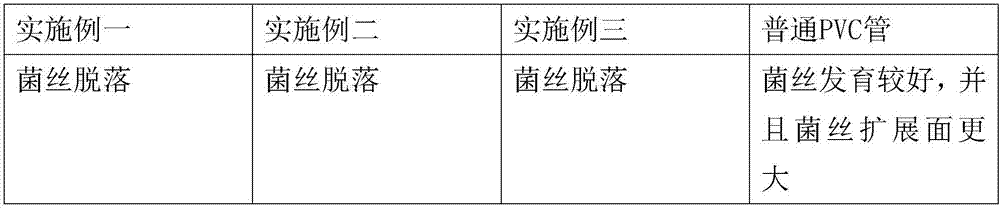

A PVC pipe and low-density technology, applied in the field of low-density PVC pipe and its preparation technology, can solve the problems of cracking of the pipe and easy mold, and achieve the effects of low bending strength, less brittleness, and improved antibacterial performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

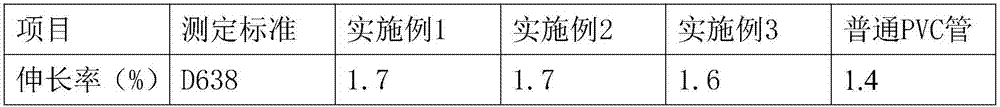

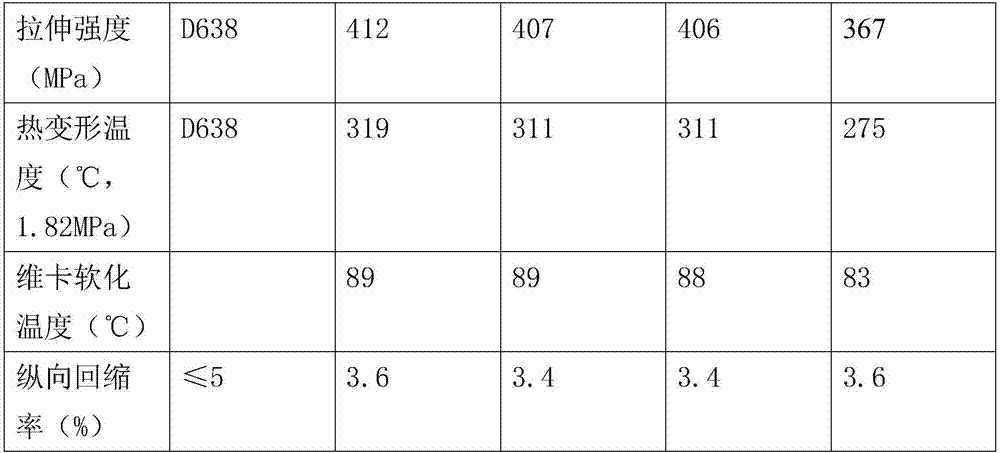

Examples

Embodiment 1

[0019] A low-density PVC pipe added with polyurethane, comprising: 150 parts by weight of PVC, 40 parts of low-density polyethylene, 8 parts of bentonite, 3.2 parts of defoamer, 6 parts of phenolic propane epoxy resin, 2.5 parts of stearic acid 1.5 parts of pearl micropowder, 0.8 parts of chitosan, 0.15 parts of paraffin, 1.4 parts of tributyl phosphate, 0.8 parts of chromium trioxide, 4 parts of calcium carbonate, 5 parts of ammonium polyphosphate, and 5 parts of polyurethane.

[0020] The PVC pipe also includes: 0.4 parts of cellulose ether, 0.4 parts of nano-zinc oxide, 0.4 parts of resveratrol, and 0.8 parts of tetrabutylphosphine chloride in terms of components by weight.

[0021] A kind of technology that prepares the low-density PVC pipe that adds polyurethane, comprises the following steps:

[0022] (1) take each component according to parts by weight;

[0023] (2) Mix each component in a mixing mixer, the mixing speed is 80-100 rpm, and the mixing time is 30-60 minut...

Embodiment 2

[0029] A low-density PVC pipe added with polyurethane, comprising: 140 parts by weight of PVC, 30 parts of low-density polyethylene, 5 parts of bentonite, 3 parts of defoamer, 5 parts of phenolic propane epoxy resin, 2 parts of stearic acid 1 part of pearl micropowder, 0.5 part of chitosan, 0.1 part of paraffin, 1.2 parts of tributyl phosphate, 0.5 part of chromium trioxide, 2 parts of calcium carbonate, 2 parts of ammonium polyphosphate, and 2 parts of polyurethane.

[0030] The PVC pipe also includes: 0.3 parts of cellulose ether, 0.3 parts of nano-zinc oxide, 0.3 parts of resveratrol, and 0.5 parts of sodium dibutylsuccinate sulfonate in terms of components by weight.

[0031] A kind of technology that prepares the low-density PVC pipe that adds polyurethane, comprises the following steps:

[0032] (1) take each component according to parts by weight;

[0033] (2) Mix each component in a mixing mixer, the mixing speed is 80-100 rpm, and the mixing time is 30-60 minutes;

...

Embodiment 3

[0040] A low-density PVC pipe added with polyurethane, comprising: 160 parts by weight of PVC, 50 parts of low-density polyethylene, 10 parts of bentonite, 3.5 parts of defoamer, 8 parts of phenolic propane epoxy resin, 3 parts of stearic acid 2 parts of pearl micropowder, 1 part of chitosan, 0.2 part of paraffin, 1.6 parts of tributyl phosphate, 1 part of chromium trioxide, 6 parts of calcium carbonate, 8 parts of ammonium polyphosphate, and 8 parts of polyurethane.

[0041] The PVC pipe further includes: 0.5 part of cellulose ether, 0.5 part of nano-zinc oxide, 0.5 part of resveratrol, and 1 part of tetrabutylphosphine chloride in terms of components by weight.

[0042] A kind of technology that prepares the low-density PVC pipe that adds polyurethane, comprises the following steps:

[0043] (1) take each component according to parts by weight;

[0044] (2) Mix each component in a mixing mixer, the mixing speed is 80-100 rpm, and the mixing time is 30-60 minutes;

[0045] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com