One-step process for preparing copper-doped tungsten trioxide composite nano-fiber material

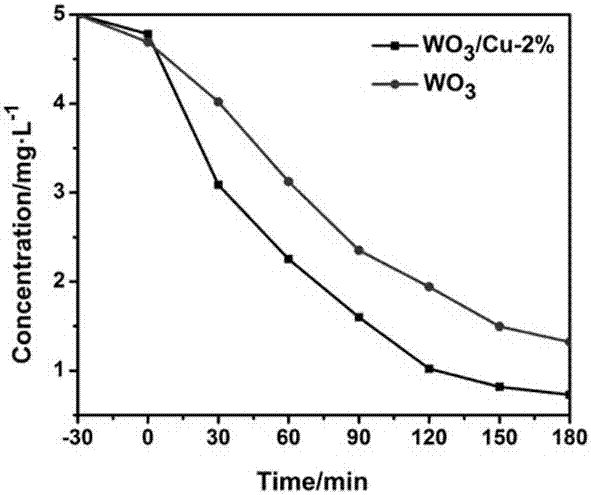

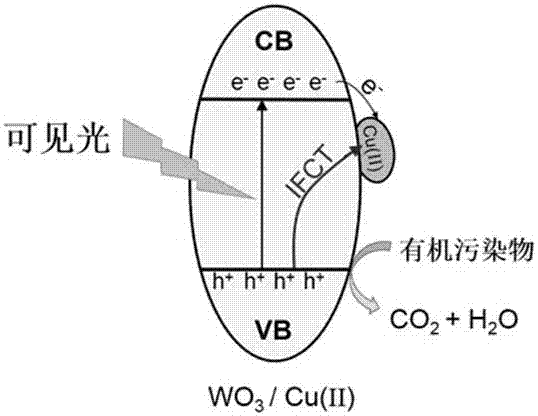

A technology of composite nanofibers and tungsten trioxide, applied in the field of nanomaterials, can solve the problems of difficulty in obtaining photocatalytic ability, low photocatalytic activity, low utilization rate of visible light, etc., and achieves improved photocatalytic degradation performance and strong photocatalytic performance. , the effect of excellent degradation of aniline performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

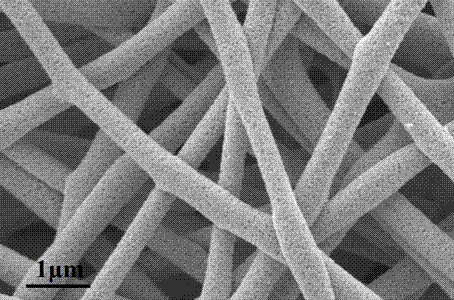

Embodiment 1

[0033] Dissolve 3.5g of commercially available ammonium metatungstate in 10ml of deionized water, add polyvinylpyrrolidone (PVP) with a molecular weight of 1,300,000 in an amount of 2g, and then add 0.05g of CuCl 2 2H 2 0, stir until the solution is blue and uniform and transparent to obtain the precursor solution; then by uniaxial electrospinning, the voltage is 25KV, the receiving distance is 15cm, and the advancing speed is 0.02ml / min, to obtain white cloth-like as-spun fibers; The fibers were calcined in a muffle furnace at 600°C with a heating rate of 3°C / min, kept for 3 hours, and cooled naturally to room temperature to obtain copper-doped tungsten trioxide composite nanofibers.

Embodiment 2

[0035] Dissolve 3.5g of hydrated ammonium metatungstate in 10ml of deionized water, add polyvinylpyrrolidone (PVP) with a molecular weight of 1300000, and add 1.5g, then add 0.08g of CuCl 2 2H 2 0, stir until the solution is blue uniform and transparent to obtain the precursor solution; then by uniaxial electrospinning, the voltage is 20KV, the receiving distance is 12cm, and the advancing speed is 0.05ml / min, to obtain white cloth-like as-spun fibers; The fibers were calcined in a muffle furnace at 650°C with a heating rate of 5°C / min, kept for 3 hours, and cooled naturally to room temperature to obtain copper-doped tungsten trioxide composite nanofibers.

Embodiment 3

[0037] Dissolve 5.0g of hydrated ammonium metatungstate in 10ml of deionized water, add polyvinylpyrrolidone (PVP) with a molecular weight of 1300000, and add 2.0g, then add 0.12g of CuCl 2 2H 2 0, stir until the solution is blue uniform and transparent to obtain the precursor solution; then by uniaxial electrospinning, the voltage is 24KV, the receiving distance is 15cm, and the advancing speed is 0.1ml / min, to obtain white cloth-like as-spun fibers; The fibers were calcined in a muffle furnace at 650°C with a heating rate of 5°C / min, kept for 3 hours, and cooled naturally to room temperature to obtain copper-doped tungsten trioxide nanofibers.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com