Preparation method of polytetrafluoroethylene hollow fiber composite film

A polytetrafluoroethylene and fiber composite technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve problems such as poor compatibility, reduce membrane area, reduce costs, and the method is simple and easy to implement. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

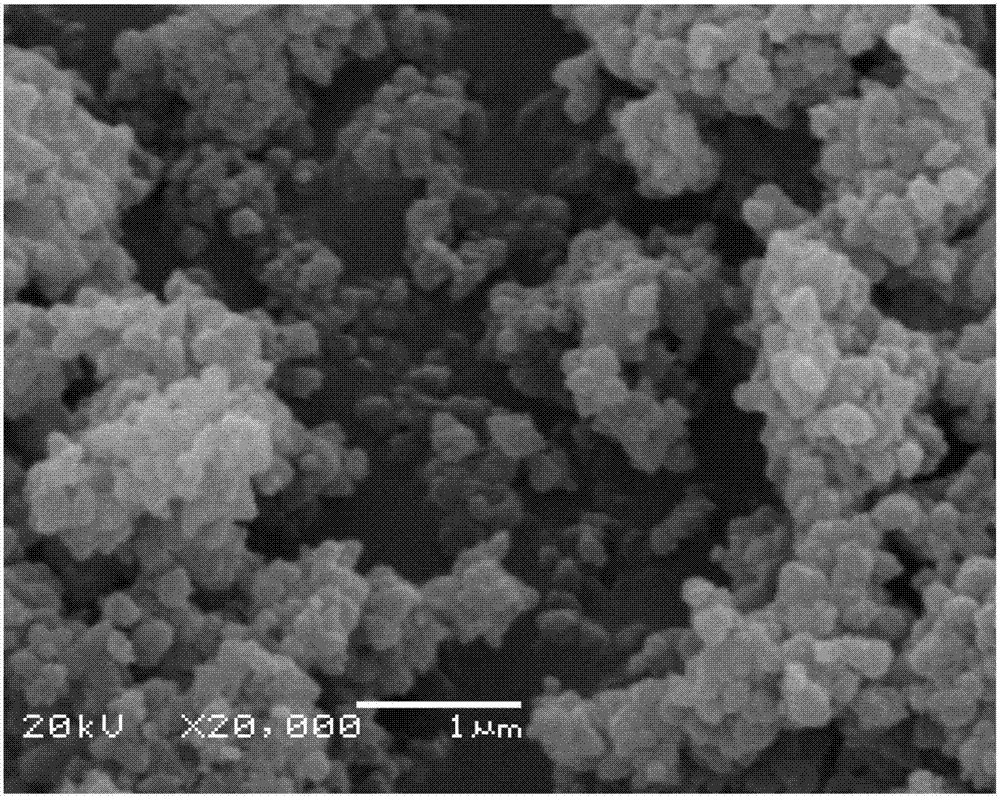

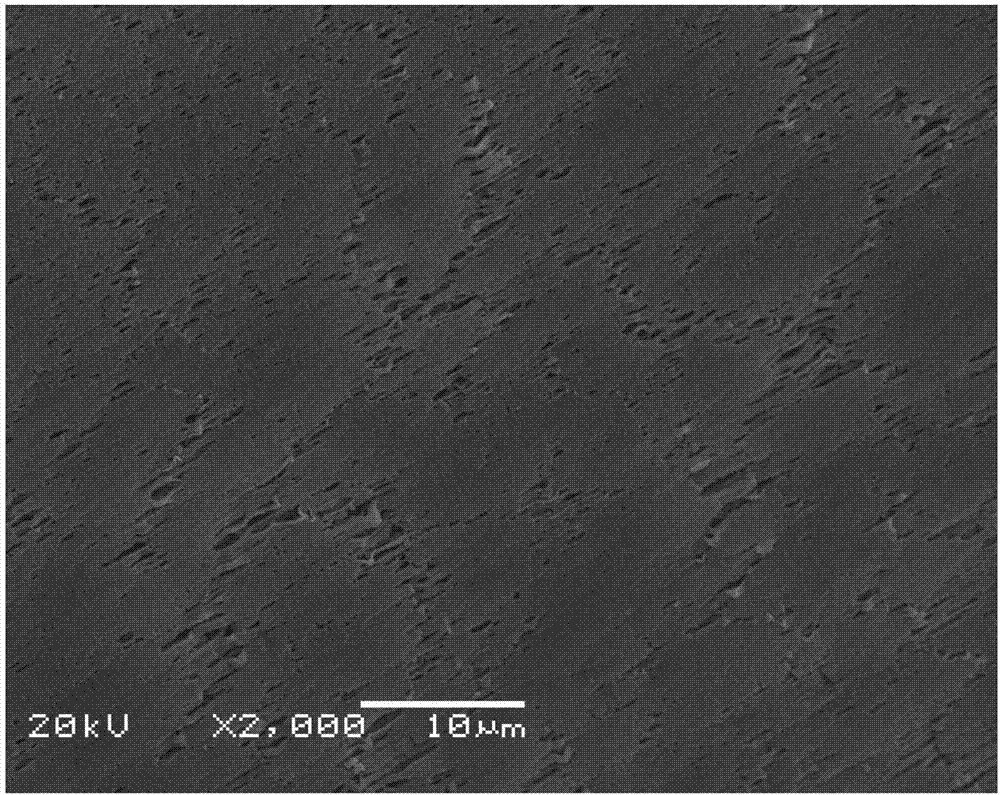

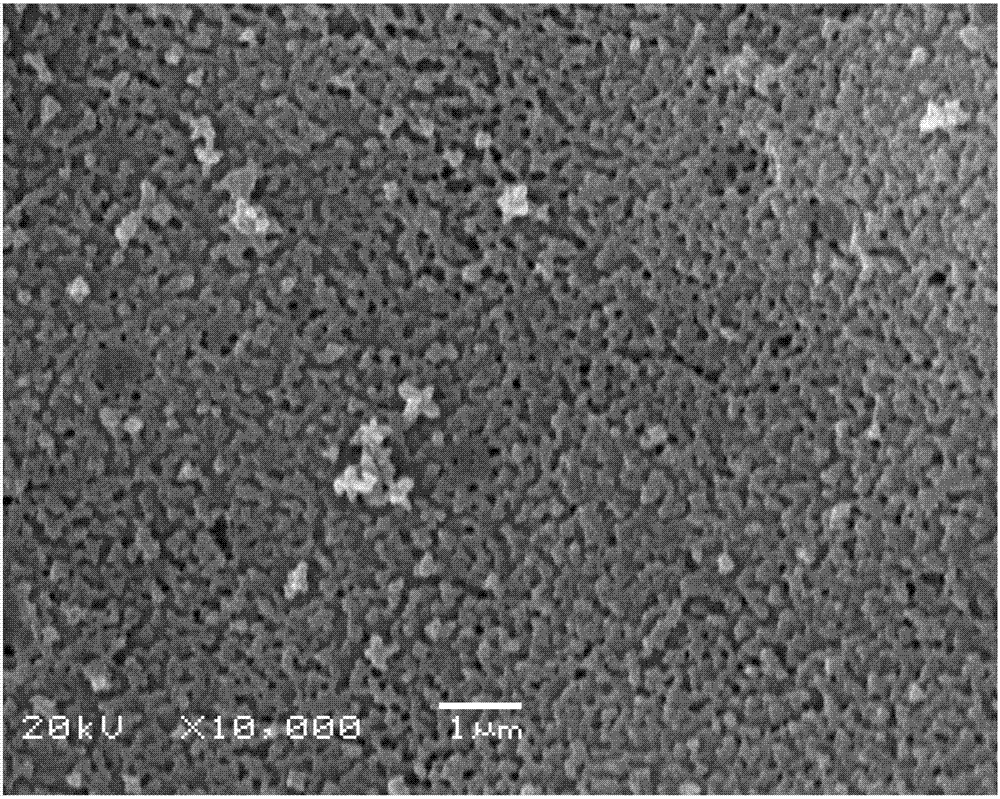

[0027] 0.2g particle diameter is the ZIF-8 seed crystal particle of 150nm (electron microscope characterization photo sees attached figure 1), 7gPFA concentrated dispersion liquid (solid content 30wt%), 80g deionized water is fully mixed and is prepared into the pre-coating seed solution, is the polytetrafluoroethylene hollow fiber membrane inner surface pre-coating seed of 0.08 μ m in average aperture (characterized by electron microscopy photo attached figure 2 ); after vacuum drying (vacuum degree: 0.1MPa) at 50°C for 3h, the film was heat-treated in a furnace at 300°C for 120s.

[0028] 0.9g of anhydrous zinc chloride and 2.5g of 2-methylimidazole were dissolved in 30g and 50g of deionized water respectively. After the two solutions were mixed and stirred evenly, the heat-treated film was placed in this solution so that the inner surface of the film Fully contact with the secondary growth film-forming solution, keep at 40°C for 6h, then wash the inner surface of the film...

Embodiment 2

[0030] 0.15g particle size is 100nmZIF-8 seed crystal particles, 5gFEP concentrated dispersion (solid content 50wt%), 70mL deionized water, 10g absolute ethanol are fully mixed to prepare a pre-coating seed solution, and the average pore diameter is 0.12μm The inner surface of the polytetrafluoroethylene hollow fiber membrane is pre-coated with seed crystals; after vacuum drying at 40°C (vacuum degree of 0.1MPa) for 5h, the membrane is heat-treated in a furnace at 280°C for 180s.

[0031] 1.325g of zinc nitrate and 3.745g of benzimidazole were dissolved in 20g and 60g of N,N-dimethylformamide (DMF) respectively. After the two solutions were mixed and stirred evenly, the heat-treated film was placed in the solution. Make the inner surface of the membrane fully contact with the secondary growth film-forming solution, keep it at 80°C for 10h, then wash the inner surface of the membrane with methanol, and dry it in vacuum at 60°C (vacuum degree is 0.1MPa) for 5h. This synthesis pr...

Embodiment 3

[0033] Mix 0.25g of ZIF-9-67 seed particles with a particle size of 300nm, 8.0g of PTFE concentrated dispersion (solid content 60wt%), 70g of deionized water, and 10mL of N,N-dimethylformamide (DMF) Prepare a pre-coating seed solution, and pre-coat the seed crystal on the outer surface of a polytetrafluoroethylene hollow fiber membrane with an average pore size of 0.2 μm; after vacuum drying at 50°C (vacuum degree of 0.1MPa) for 3 hours, place the membrane at 340°C Heat treatment in the furnace for 100s.

[0034] Dissolve 1.28g of cobalt nitrate hexahydrate, 0.46g of benzimidazole, and 0.32g of 2-methylimidazole in 20g of N,N-dimethylformamide (DMF). Place the final membrane in this solution, make the outer surface of the membrane fully contact with the secondary growth film-forming solution, keep it at 130°C for 8 hours, and then wash the outer surface of the membrane with N,N-dimethylformamide (DMF) , vacuum-dried at 80°C (vacuum degree 0.1MPa) for 4h. This synthesis proce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com