Preparation method of nitrogen-doped graphene-loaded metal monatomic catalysts

A nitrogen-doped graphene, metal-loaded technology is applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., to achieve the effect of simple and practical preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0019] The preparation method of a nitrogen-doped graphene-supported metal single-atom catalyst provided by the present invention uses disodium salt of ethylenediaminetetraacetic acid as a complexing agent to form a stable complex with metal ions in a liquid phase by ion exchange reaction After being evaporated to dryness, it is fully mixed with an alkali metal salt, and a nitrogen-doped graphene-supported metal single-atom catalyst is obtained by synchronous pyrolysis conversion. The preparation method mainly includes the following steps:

[0020] 1) Add nitrogen-containing organic compound ethylenediaminetetraacetic acid disodium salt and metal salt into deionized water, the mass ratio of the two is between 1000:1 and 100:1, and mix evenly to obtain a molar concentration of 0.001 to 0.5 mol / L solution; then conduct ion exchange reaction at 40-120°C for 0.5-6 hours to obtain a stable complex, evaporate to dryness and obtain solid powder of the complex;

[0021] 2) Fully mix t...

Embodiment 1

[0028] Preparation of graphene-supported Pd single-atom catalysts:

[0029] Step 1: Add 4g of ethylenediaminetetraacetic acid disodium salt and 12mg of sodium tetrachloropalladate into deionized water, stir with magnetic force, react at 80°C for 2h, and then evaporate to dryness;

[0030] Step 2, fully mix 4 g of the product obtained in step 1 with 30 g of sodium carbonate, put it into a tube furnace, heat-treat at 800° C. for 3 hours under an inert atmosphere, and then cool naturally to room temperature to obtain a black mixture;

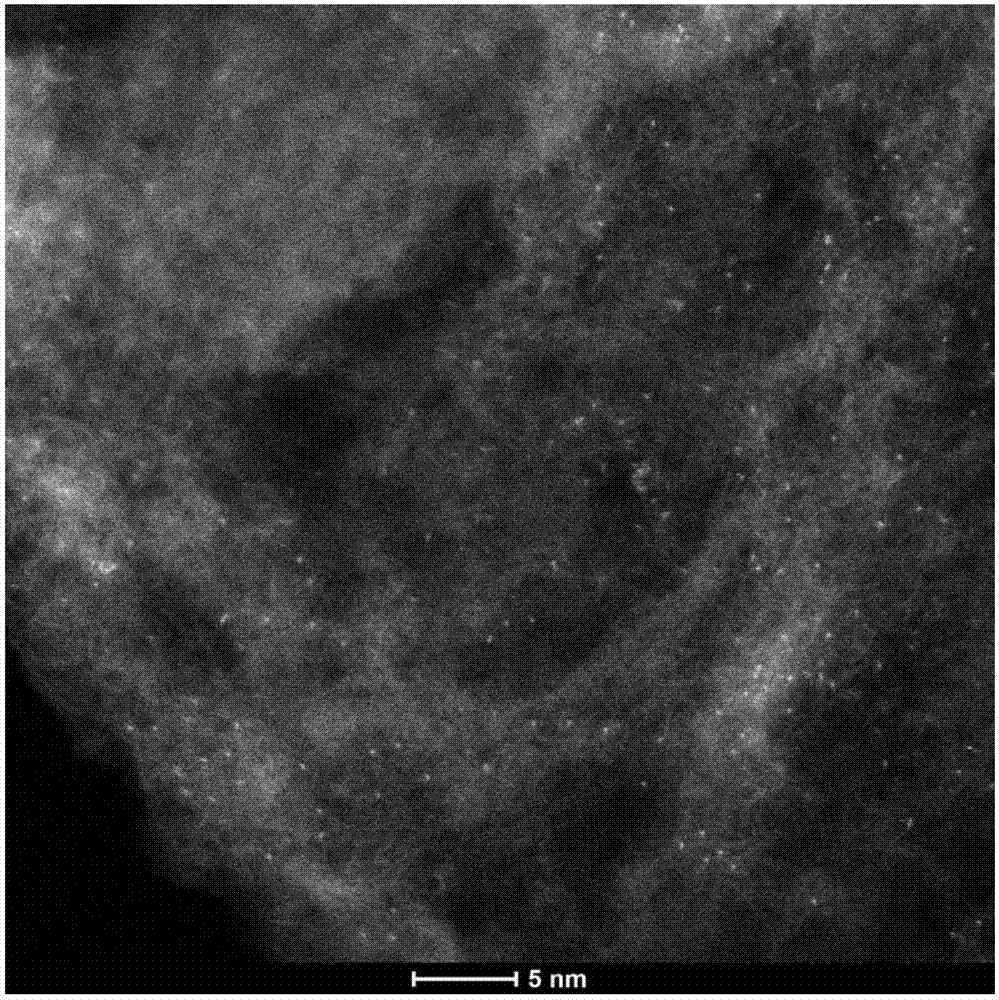

[0031] In step 3, the black mixture obtained in step 2 is sequentially washed and dried with 1M hydrochloric acid solution, pure water and absolute ethanol to obtain a nitrogen-doped graphene-supported metal Pd single-atom catalyst. Such as figure 1Shown is the image of the graphene-supported Pd single-atom catalyst under the high-angle annular dark-field scanning transmission electron microscope, the bright metal Pd single atoms are uniformly dis...

Embodiment 2

[0033] Preparation of graphene-supported Pt single-atom catalysts:

[0034] Step 1, add 6g of ethylenediaminetetraacetic acid disodium salt and 5.6mg of potassium hexachloroplatinate into deionized water, stir with magnetic force, react at 80°C for 6h, and then evaporate to dryness;

[0035] Step 2, fully mix 6 g of the product obtained in step 1 with 30 g of sodium sulfate, put it into a tube furnace, heat-treat at 850° C. for 2 hours under an inert atmosphere, and cool it down to room temperature naturally to obtain a black mixture;

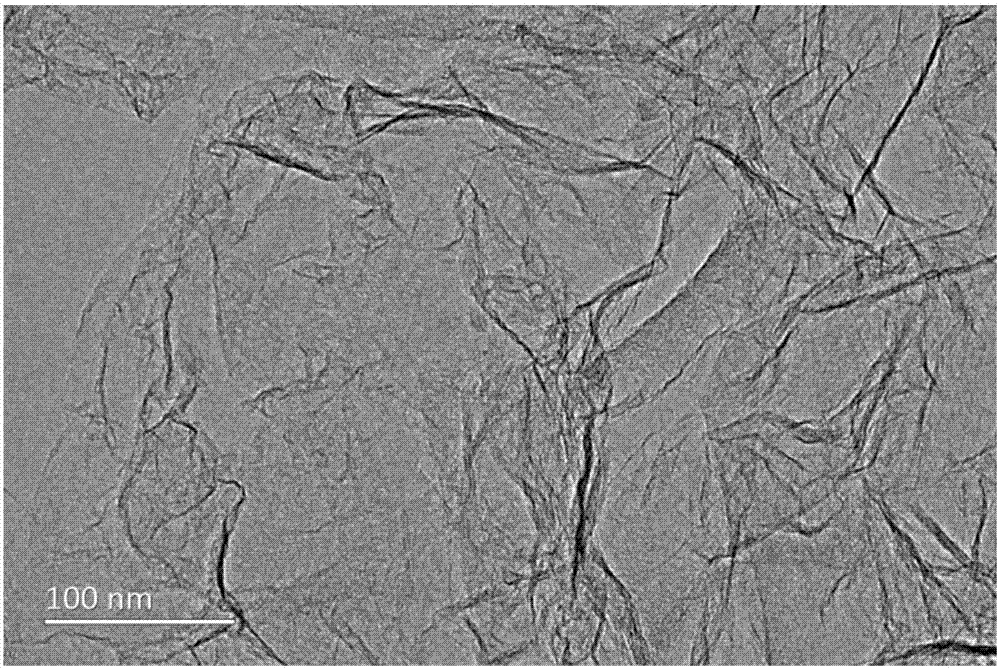

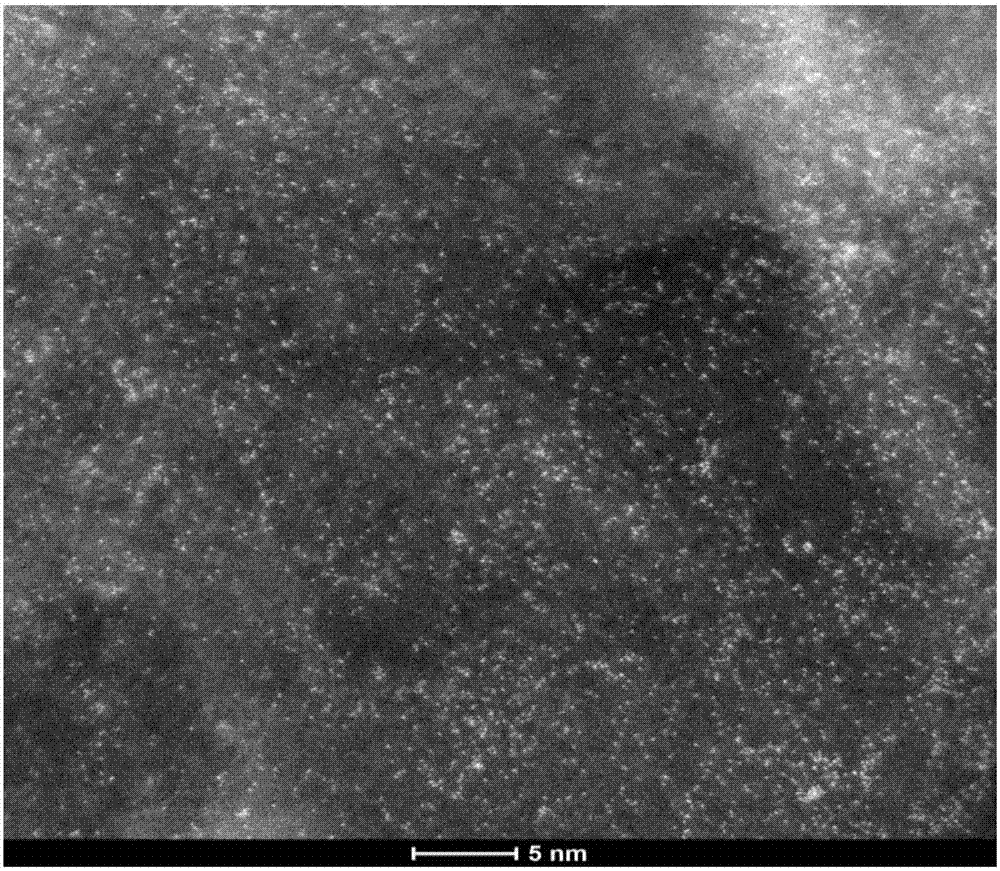

[0036] In step 3, the black mixture obtained in step 2 is sequentially washed and dried with 0.5M sulfuric acid solution, pure water and absolute ethanol to obtain a metal Pt single-atom catalyst supported by nitrogen-doped graphene. Such as figure 2 Shown is the image of the graphene-supported Pt single-atom catalyst under a transmission electron microscope. The overall morphology is an ultrathin two-dimensional nanostructure, which has typi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com