One-pot method for preparing ascidian nano-microcrystalline cellulose/rubber nanocomposites

A nano-microcrystalline and rubber-nano technology, applied in the field of rubber, can solve problems such as weak interfacial bonding, and achieve the effects of high crystallinity and molecular weight, large aspect ratio, and high length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

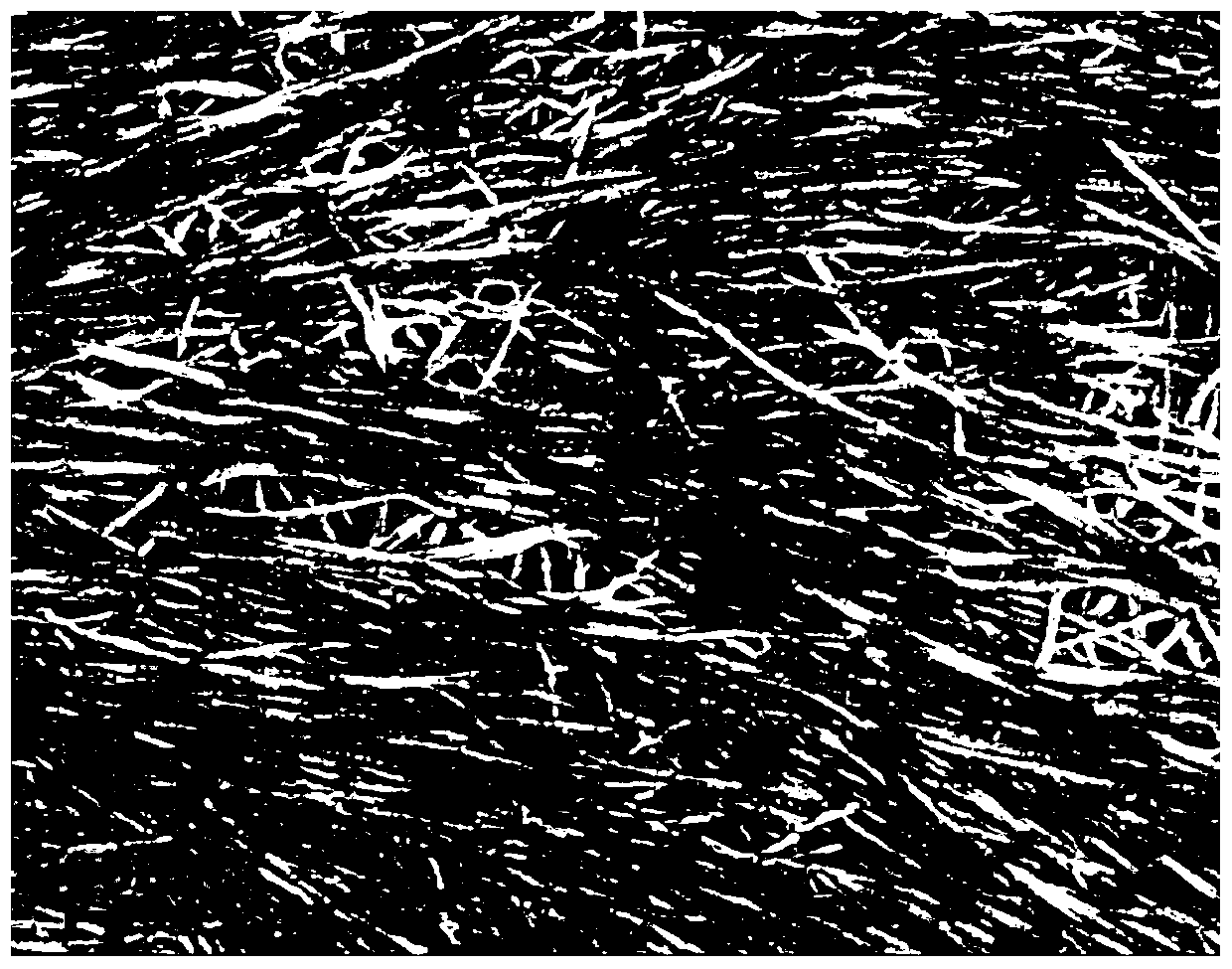

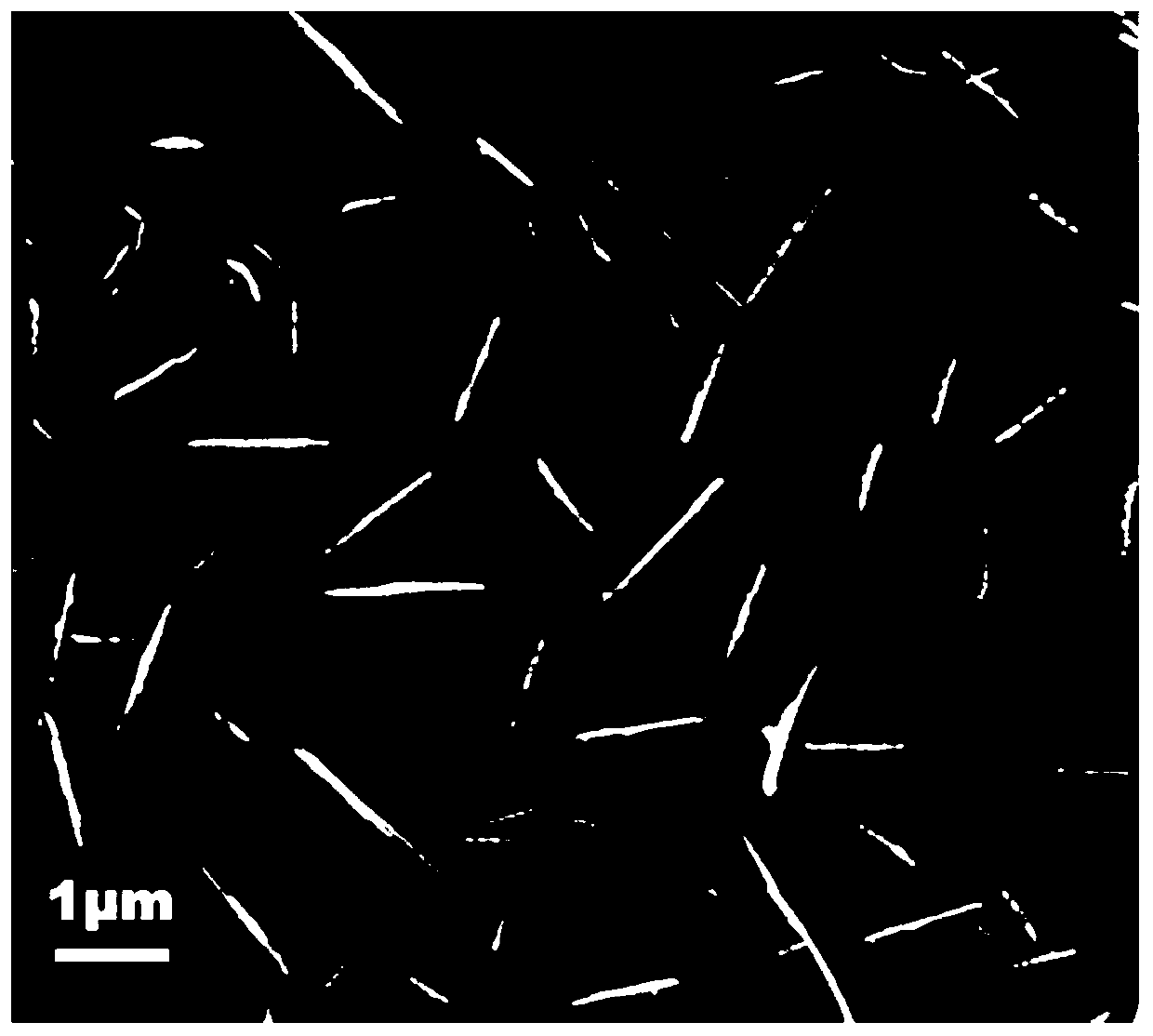

[0039] The preparation method of the ascidian nano-microcrystalline cellulose suspension is as follows: soak and clean the ascidian and dissect the capsule; soak the capsule in strong alkali at 40°C for 24 hours to remove the protein and lipid contained therein; Under the condition of 50°C, the capsules from which proteins and lipids have been removed were reacted in a bleaching solution made of glacial acetic acid and sodium hypochlorite for 6 hours, and repeated twice, each time the previous bleaching solution was replaced until the capsules turned white. ; dry the bleached powdered cellulose crystals in an air blast drying oven at 30° C., and pulverize them to micron or millimeter scale; use sulfuric acid with a concentration of 55-65 wt % to pulverize the powdered cellulose crystals Carry out acid hydrolysis, the acid hydrolysis temperature is 40 ℃, time 5h, add a large amount of deionized water after the reaction, dilute the solution and lower the temperature to terminate ...

Embodiment 5~8

[0074] The preparation method of the ascidian nano-microcrystalline cellulose suspension is as follows: soak and wash the ascidian and dissect the capsule; soak the capsule in strong alkali at 60°C for 12 hours to remove the protein and lipid contained therein; Under the condition of 90°C, react the capsules from which proteins and lipids have been removed in the bleaching solution made of glacial acetic acid and sodium hypochlorite for 12 hours, and repeat the process 6 times, each time the previous bleaching solution needs to be replaced until the capsules turn white ; dry the bleached powdered cellulose crystals in an air blast drying oven at 30° C., and pulverize them to micron or millimeter scale; use sulfuric acid with a concentration of 55-65 wt % to pulverize the powdered cellulose crystals Acid hydrolysis, acid hydrolysis temperature is 60 ℃, time 0.5h, add a large amount of deionized water after the reaction, dilute the solution and lower the temperature to terminate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com