Fast-response highly-sensitive polymer-based gas-sensitive material, and preparation method and application thereof

A high-sensitivity, gas-sensing material technology, which is applied in the field of fast-response and high-sensitivity polymer-based gas-sensing materials and its preparation, can solve the problems of reduced gas-sensing response time and long response time, and achieve low initial resistance , fast response, high gas sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

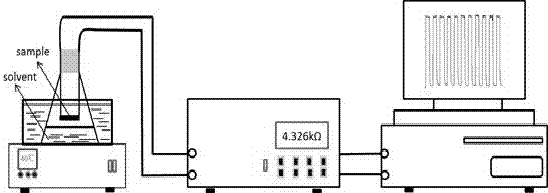

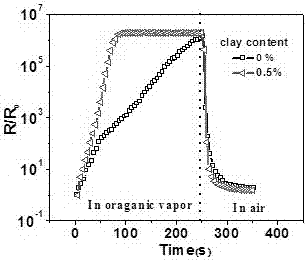

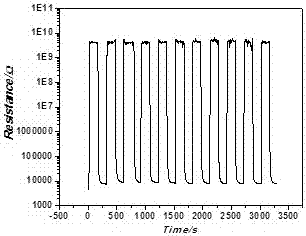

Method used

Image

Examples

Embodiment 1

[0031] (1) Filler pre-dispersion: Blend 0.5 parts of quaternary ammonium salt-modified montmorillonite and 16 parts of carbon nanofibers, add n-hexane, and then disperse at room temperature with ultrasound at 10000 Hz for 20 min to obtain carbon nanofibers and the suspension dispersion of quaternary ammonium salt modified montmorillonite, the consumption of n-hexane is 20ml n-hexane for 1g carbon nanofiber;

[0032] (2) Preparation of carbon nanofiber / quaternary ammonium salt modified montmorillonite / vinyl silicone oil blend: first dissolve 100 parts of liquid vinyl silicone oil in n-hexane, and then mix it with carbon nanofiber and quaternary ammonium salt The mixed suspension of the modified montmorillonite was mixed and stirred at a high speed, and the conditions were as follows: first, stir at 500 rpm for 10 min, then stir at 2000 rpm for 20 min, and finally stir at 3000 rpm for 20 min; obtain carbon nanofiber / quaternary ammonium salt modified Mixed solution of montmorillo...

Embodiment 2

[0035] (1) Filler pre-dispersion: blend 7 parts of cetyltrimethylammonium bromide montmorillonite and 35 parts of carbon black, add solvent tetrahydrofuran, and then use ultrasonic dispersion at 100000 Hz for 10 min at room temperature , to obtain a suspension dispersion of carbon black and montmorillonite; THF consumption is 10 ml THF for 1 g of carbon black;

[0036] (2) Preparation of carbon black / cetyltrimethylammonium bromide montmorillonite / vinyl silicone oil blend: first dissolve 100 parts of vinyl silicone oil in tetrahydrofuran, and then mix it with carbon black and hexadecane The mixed suspension of trimethylammonium bromide montmorillonite was mixed, and stirred at a high speed, the conditions were as follows: firstly stirred at 500 rpm for 10 min, then stirred at 2000 rpm for 15 min, and finally stirred at 3000 rpm for 15 min; obtained carbon black / 16 A mixed solution of alkyltrimethylammonium bromide montmorillonite / vinyl silicone oil, the feeding ratio of vinyl s...

Embodiment 3

[0039] (1) Filler pre-dispersion: In parts by weight, blend 0.05 parts of montmorillonite and 4 parts of silane-modified carbon tubes, add solvent toluene, and then disperse by ultrasonic at 5000 Hz for 30 min at room temperature. Obtain the suspension dispersion liquid of carbon tube and montmorillonite; The consumption of toluene is that 1 g carbon tube uses 20 ml solvent;

[0040](2) Preparation of carbon tube / montmorillonite / vinyl silicone oil blend: first dissolve 100 parts of vinyl silicone oil in toluene, and then mix it with the mixed suspension of carbon tube and montmorillonite. And high-speed stirring, the conditions are as follows: first, stir at 500 rpm for 10 minutes, then stir at 2000 rpm for 15 minutes, and finally stir at 3000 rpm for 15 minutes; a mixed solution of carbon tubes / montmorillonite / silicone rubber is obtained. The feeding ratio of vinyl silicone oil is: 3 ml of toluene is put into 1 g of vinyl silicone oil;

[0041] (3) Forming of carbon tube / mon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com