Membrane technology-based orange juice preparation method and system

A production method and membrane technology, applied in juice extraction, food processing, food science, etc., can solve the problems of backward processing technology and equipment, low product quality, low market competitiveness, etc., and achieve low cost and high stability Sexuality, prolonging the pollution cycle, and improving the viability of enterprises

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] A method for making orange juice based on membrane technology, comprising:

[0045] (1) Clean citrus and fresh orange fruits to remove foreign matter on the peel;

[0046] (2) Peel and squeeze the cleaned citrus and fresh orange fruits to obtain fresh orange juice;

[0047] (3) The fresh orange juice is separated by ceramic membrane filtration, the concentrated liquid obtained from the separation is fruit pulp, and the permeated liquid is clear juice;

[0048] (4) The clear juice is concentrated through the forward osmosis membrane to obtain concentrated orange juice;

[0049] (5) After pasteurization, the pulp concentrate obtained in step (3) is thoroughly mixed with the concentrated orange juice obtained in step (4) to obtain reconstituted raw juice, which is the final orange juice product.

[0050] The cleaning water in step (1) is preferably the product water produced during the regeneration process of the draw solution used in the concentration treatment of the f...

Embodiment 2

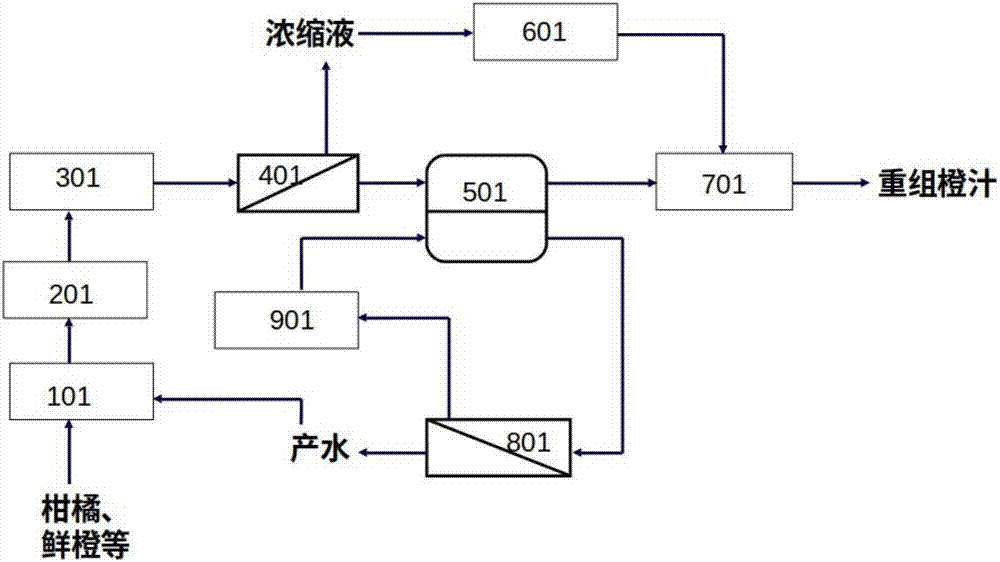

[0058] A kind of orange juice production system based on membrane technology, comprising: cleaning tank 101, cleaning tank 101 is used to provide the place for cleaning citrus, fresh orange fruits; juicer 201, juicer 201 is used for cleaning and Extract juice from peeled citrus and fresh orange fruits to obtain fresh orange juice; ceramic membrane device 401, ceramic membrane device 401 is used to filter and separate fresh orange juice, and obtain concentrated liquid as fruit pulp, and permeate For clear juice; forward osmosis membrane device 501, forward osmosis membrane device 501 is used to concentrate the clear juice and obtain concentrated orange juice; pasteurization tank 601, pasteurization tank 601 is used for the fruit pulp obtained by ceramic membrane device 401 The concentrate is pasteurized; the mixing tank 701 is used to fully mix the pasteurized pulp concentrate and the concentrated orange juice obtained through forward osmosis to obtain recombined orange juice. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Membrane flux | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com