Surface treatment agent, enamelled steel and parts coated with the surface treatment agent

A technology of surface treatment agent and enamel, applied in the direction of surface coating liquid device, coating, metal material coating process, etc., can solve the problem of increasing the cost of coating process, not involving acid and alkali resistance and solvent resistance, Process complexity and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

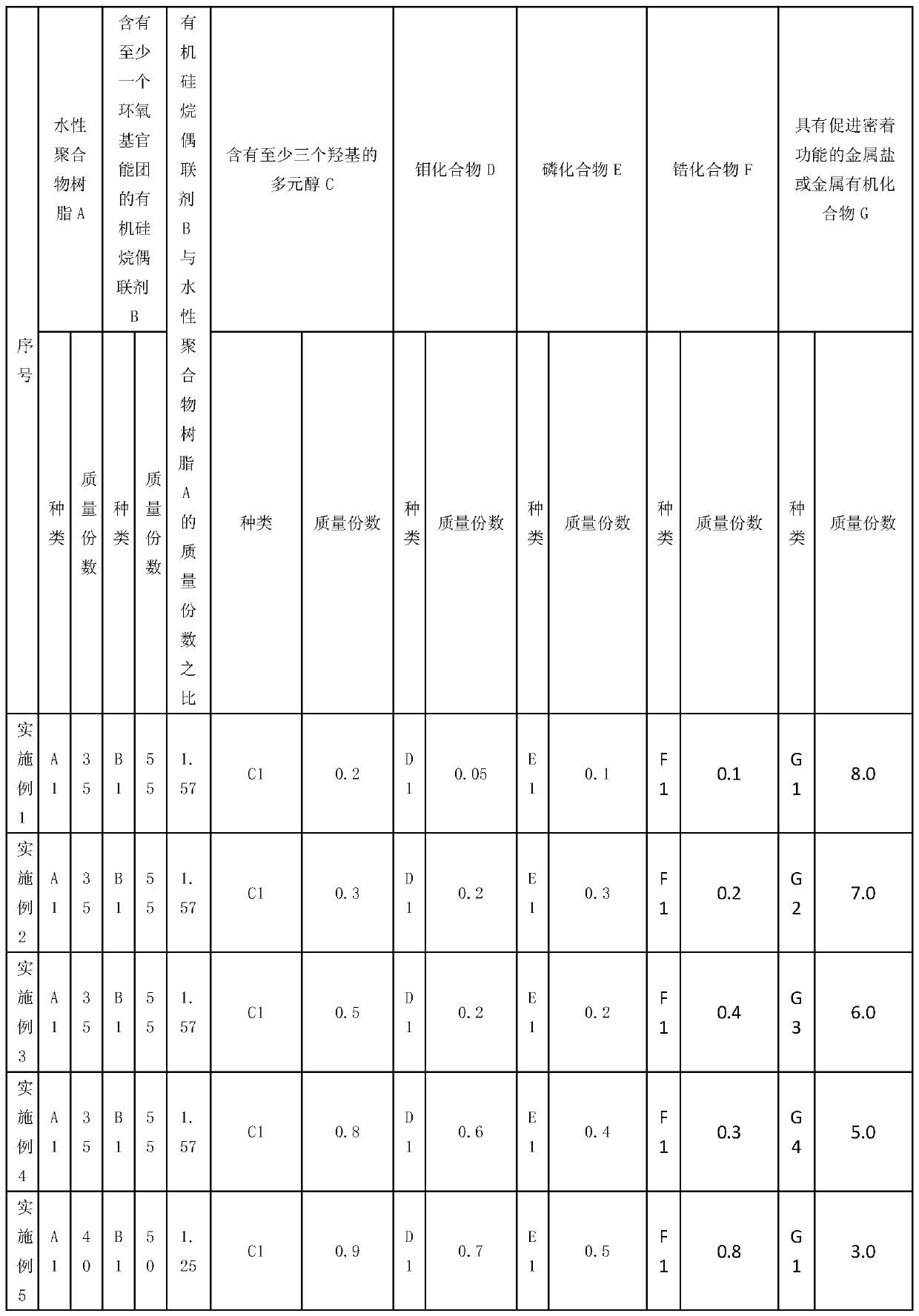

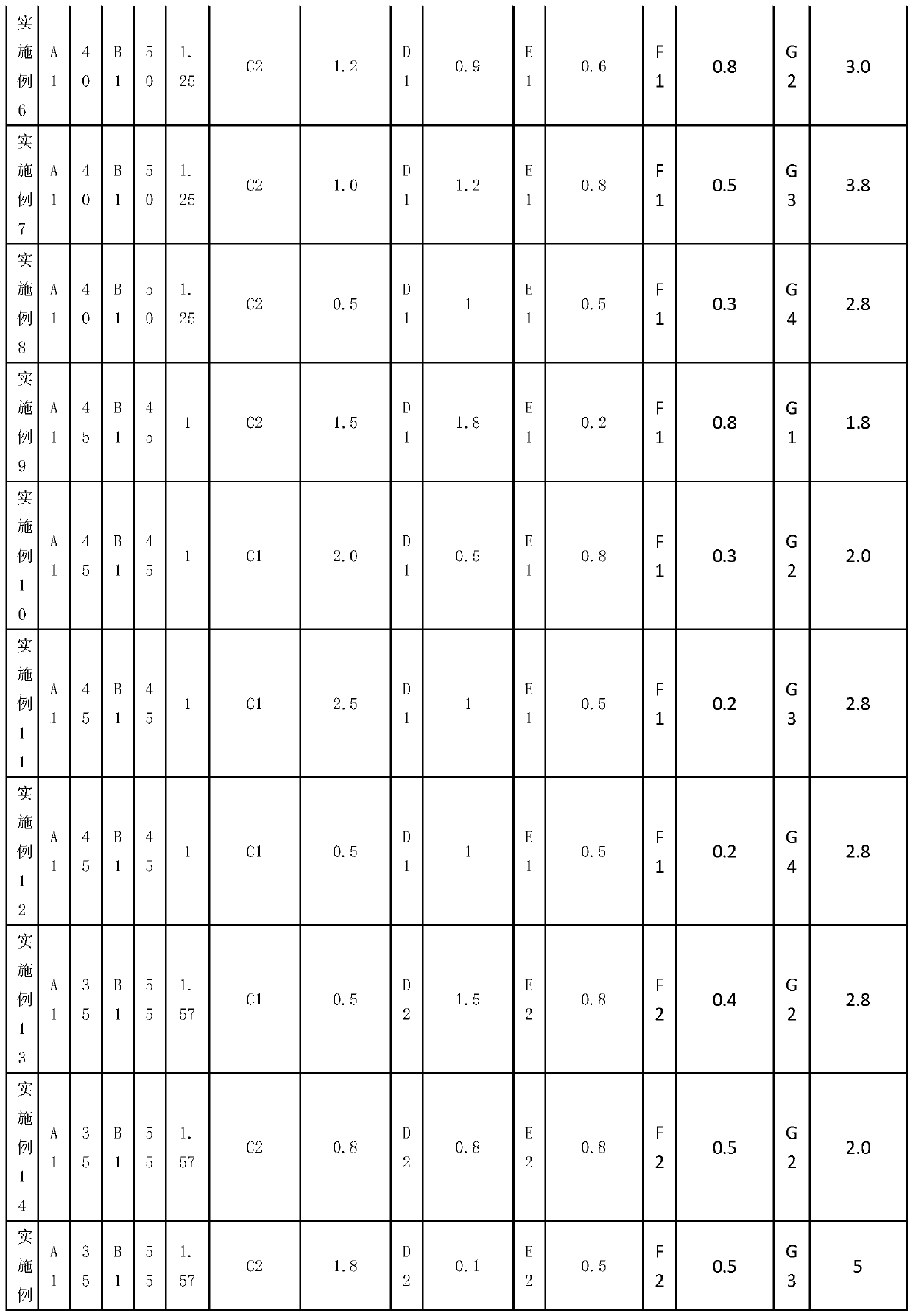

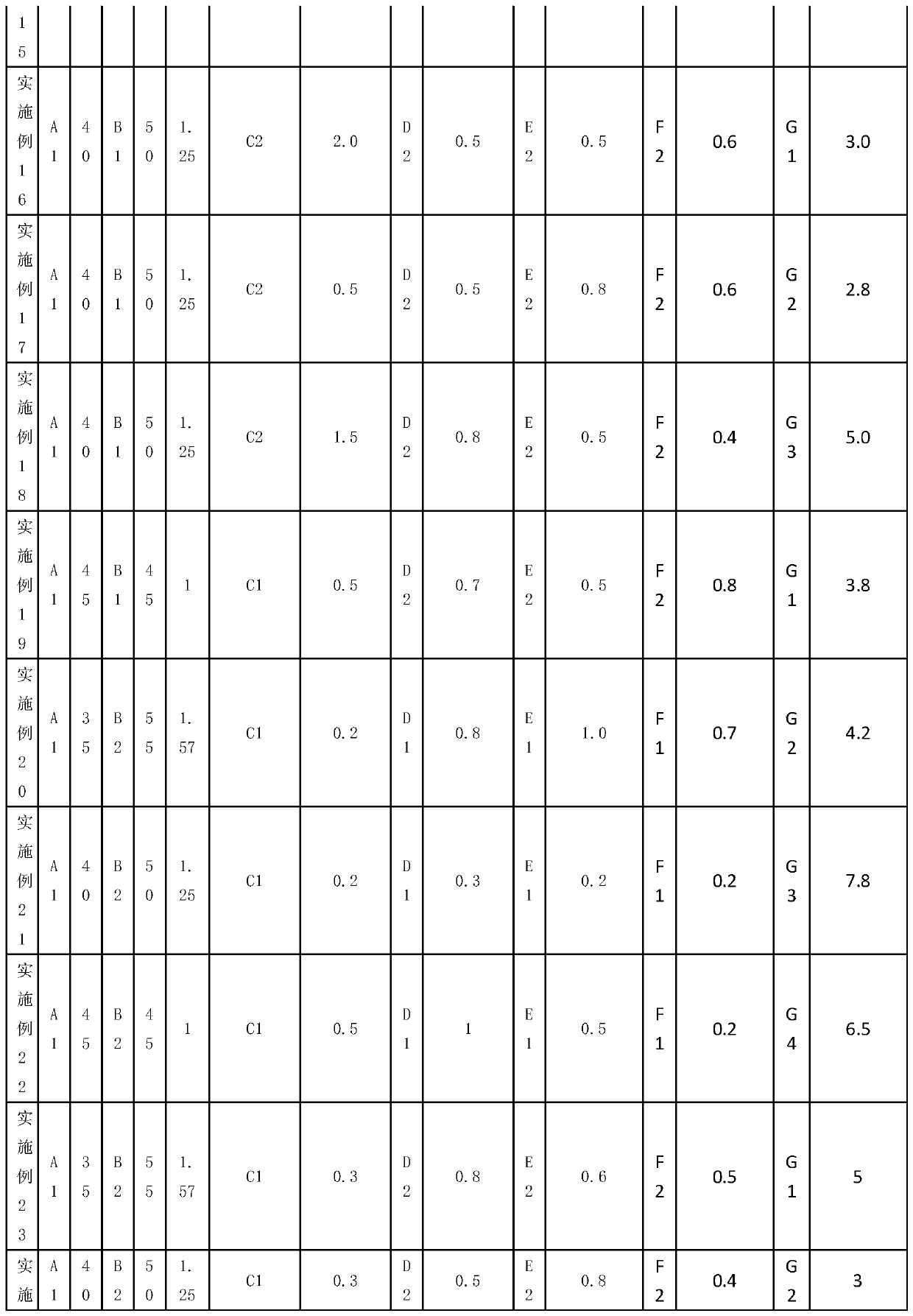

Embodiment 1-37 and comparative example 1-8

[0089] The enamelled steel product of embodiment 1-37 and comparative example 1-8 adopts the following steps to make:

[0090] (1) On the steel substrate for enamelling, adopt the method of roller coating to evenly coat the surface treatment agent configured according to Table 1; the steel substrate for enamelling all adopts the steel plate of 0.8mm steel type model DC04ED (this steel type model is also called BTC4D, According to GB / T 13790-2008, use steel types suitable for enamelling and deep drawing)

[0091] (2) keep the surface treatment agent coated in the solidification step (1) at a temperature of 100-180°C for 30s to obtain a steel plate with an organic composite coating on the surface; and control the coating pressure and the amount of the surface treatment agent to make The dry film weight of the organic composite coating is 0.6-1.0g / m 2 Within the range, the specific parameters are shown in Table 2.

[0092] (3) Spray and clean the surface of the steel substrate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com