Method and system for continuously preparing 5-hydroxymethylfurfural and derivative thereof

A technology of hydroxymethyl furfural and alkoxymethyl furfural, applied in chemical instruments and methods, separation methods, chemical/physical processes and other directions, can solve the problems affecting the high yield generation of target products and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

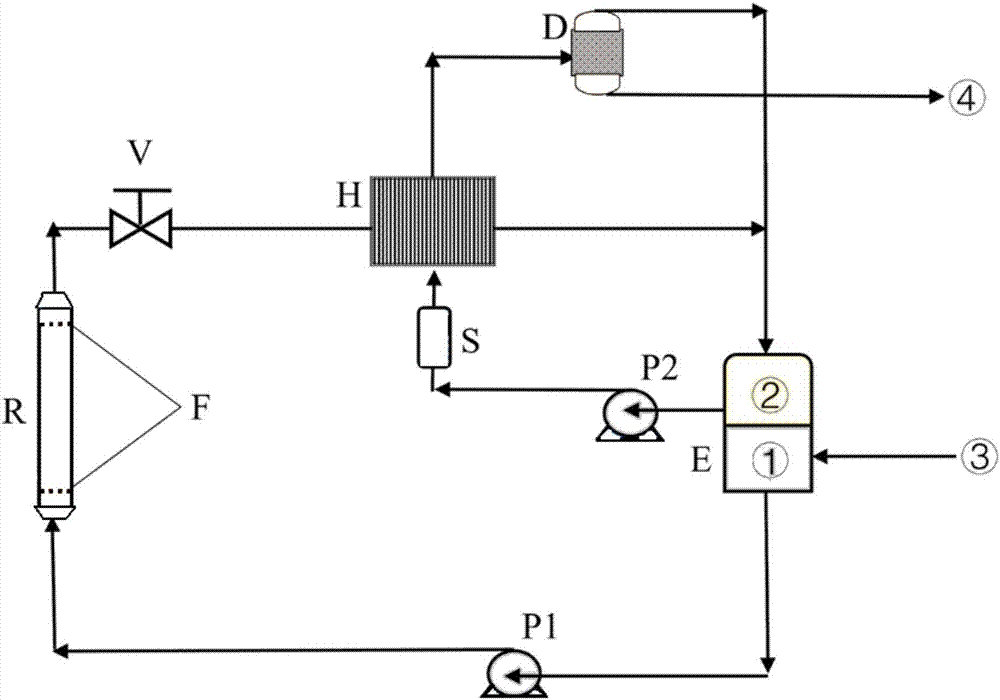

Image

Examples

Embodiment 1

[0101] 5-HMF was prepared by using fructose as raw material and HCl as catalyst.

[0102] An acid and alkali-resistant steel pipe with outer diameter OD=15.8mm, pipe wall thickness d=1.25mm, and pipe volume V=20ml is selected as the reaction device. The polar reaction phase consisted of 28ml water + 12ml DMSO. The non-polar extract phase consisted of 24ml methyl isobutyl ketone + 16ml 2-butanol. The concentration of fructose in the polar reaction phase was 5 wt.%. The concentration of HCl in the polar reaction phase is 0.2mol / L. The flow rate of the reaction solution was 10 ml / min (empty time = 2 min). The reaction temperature is 170° C., the reaction time is 30 minutes, and the reaction column pressure is 0.1 Mpa. The polar reaction liquid undergoes a full cycle reaction in the reaction device and the extraction device. After the reaction, the conversion rate of fructose was detected by high performance liquid chromatography to be 99%, and the selectivity of 5-HMF was 93...

Embodiment 2

[0104] 5-HMF was prepared with fructose as raw material and H3PO4 as catalyst.

[0105] Choose the same reaction device and reaction conditions as in Example 1. Change the catalyst to 0.2mol / L H3PO4. After the reaction, the conversion rate of fructose was detected by high performance liquid chromatography to be 98%, and the selectivity of 5-HMF was 91%.

Embodiment 3

[0107] 5-HMF was prepared with fructose as raw material and phosphotungstic acid as catalyst.

[0108] Choose the same reaction device and reaction conditions as in Example 1. Change the catalyst to 0.2mol / L phosphotungstic acid. After the reaction, the conversion rate of fructose was detected by high performance liquid chromatography to be 100%, and the selectivity of 5-HMF was 86%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com