Preparation of longan seed resistant starch

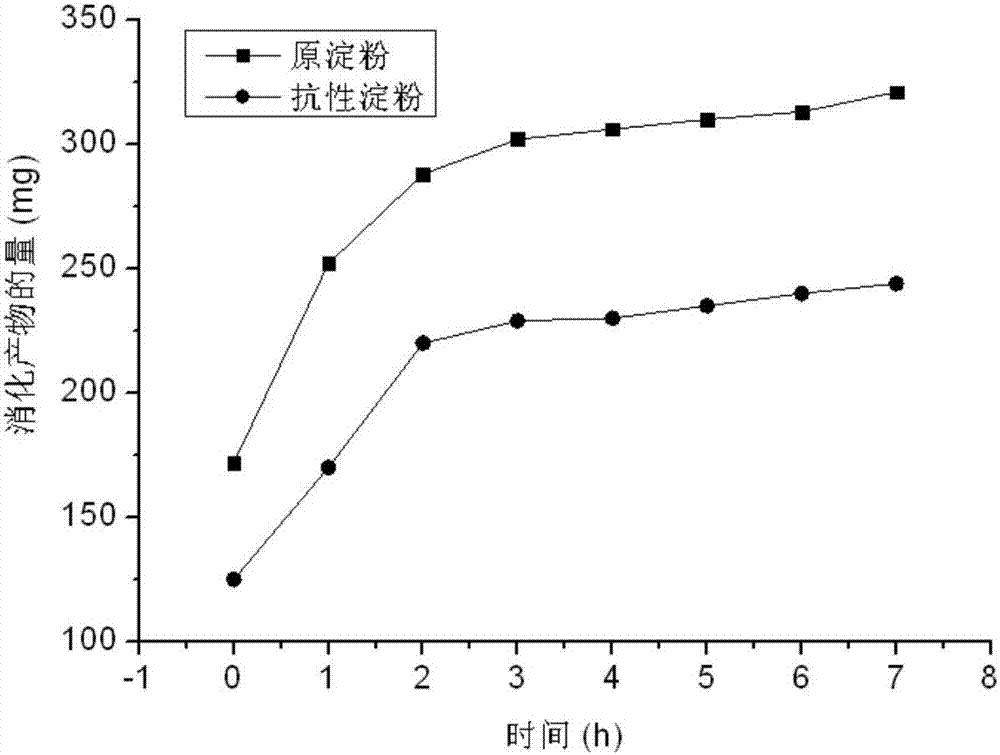

A technology of nuclear resistance and longan kernel, which is applied in the field of preparation of longan kernel resistant starch, can solve the problems of poor development and utilization, waste of resources, less research on longan kernel resistant starch, etc., and achieve an increase in application range, Effect of reduced sugar content and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A kind of preparation of longan kernel resistant starch, specifically comprises the following steps:

[0029] (1) After selecting fresh longan kernels to remove impurities and clean them, remove the epidermis and crush them, pour them into a beater for beating, filter with a 90-mesh sieve to obtain starch slurry, and set aside;

[0030] (2) Add glucose oxidase that accounts for 5% of the volume of the starch slurry in step (1) to the starch slurry in step (1), add 2 times aseptic water and stir evenly, then enzymatically react at 30°C for 1 hour, and beat with D201 Pore resin anion exchange obtains filtrate, standby;

[0031] (3) add citric acid-acetic acid solution in the filtrate of step (2), leave standstill 10min, then add tris hydroxymethyl aminomethane buffer solution to adjust pH value, adjust to pH value 7, obtain starch liquid, for subsequent use;

[0032] (4) Toughen the starch solution in step (3), wherein the water content is 40%, the temperature is 60°C,...

Embodiment 2

[0038] A kind of preparation of longan kernel resistant starch, specifically comprises the following steps:

[0039] (1) After selecting fresh longan kernels to remove impurities and clean them, remove the epidermis and crush them, pour them into a beater for beating, filter through a 100-mesh sieve to obtain starch slurry, and set aside;

[0040] (2) Add glucose oxidase, which accounts for 6.5% of the volume of the starch slurry in step (1), to the starch slurry in step (1), add 2.5 times of sterile water and stir evenly, then enzymatically react at 33°C for 1.5h, and pass through D201 Perforated resin anion exchange obtains filtrate, standby;

[0041] (3) Add citric acid-acetic acid solution to the filtrate of step (2), let it stand for 13 minutes, then add tris buffered solution to adjust the pH value, and adjust the pH value to 8 to obtain the starch liquid for subsequent use;

[0042] (4) Perform toughening treatment on the starch liquid in step (3), wherein the water co...

Embodiment 3

[0048] A kind of preparation of longan kernel resistant starch, specifically comprises the following steps:

[0049] (1) After selecting fresh longan kernels to remove impurities and clean them, remove the epidermis and break them, pour them into a beater for beating, filter with a 105-mesh sieve to obtain starch slurry, and set aside;

[0050] (2) Add glucose oxidase, which accounts for 8% of the volume of the starch slurry in step (1), to the starch slurry in step (1), add 3 times of sterile water and stir evenly, then enzymatically react at 35°C for 2 hours, and beat with D201 Pore resin anion exchange obtains filtrate, standby;

[0051] (3) Add citric acid-acetic acid solution to the filtrate of step (2), let it stand for 15 minutes, then add tris buffered solution to adjust the pH value, and adjust the pH value to 9 to obtain the starch liquid for subsequent use;

[0052] (4) toughen the starch liquid in step (3), wherein the moisture content is 60%, the temperature is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com