Composition for preparing antibacterial polyurethane, antibacterial polyurethane and preparation method of antibacterial polyurethane

A technology for polyurethane and composition is applied in the field of preparing antibacterial polyurethane composition, which can solve the problems of bacteria being prone to drug resistance, environmental pollution, decline in antibacterial activity, etc., and achieves efficient and easy process, avoiding environmental pollution, and antibacterial activity. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] The present invention also provides a kind of preparation method of antibacterial polyurethane, comprises the following steps:

[0048] (1) Weigh each raw material in the above-mentioned composition for preparing antibacterial polyurethane; mix polymer diol and diisocyanate at normal temperature, and under nitrogen protection, heat up to 60~90°C such as 60°C, 70°C ℃, 80℃ or 90℃ for stirring reaction;

[0049] (2) Cool the mixture after step (1) to 35-50°C, such as 35°C, 38°C, 40°C, 43°C, 45°C or 50°C, etc., and add an appropriate amount of dimethylformamide (technical Technicians can determine the appropriate amount according to actual needs), chain extender I, chain extender II and chain extender III, and then heat up to 60-90°C such as 60°C, 65°C, 70°C, 75°C, 80°C, React at 85°C or 90°C;

[0050] (3) cooling the mixture reacted in step (2) to normal temperature, adding alkynyl-modified 1,2-benzisothiazolin-3-one and a first catalyst for reaction to obtain antibacter...

Embodiment 1

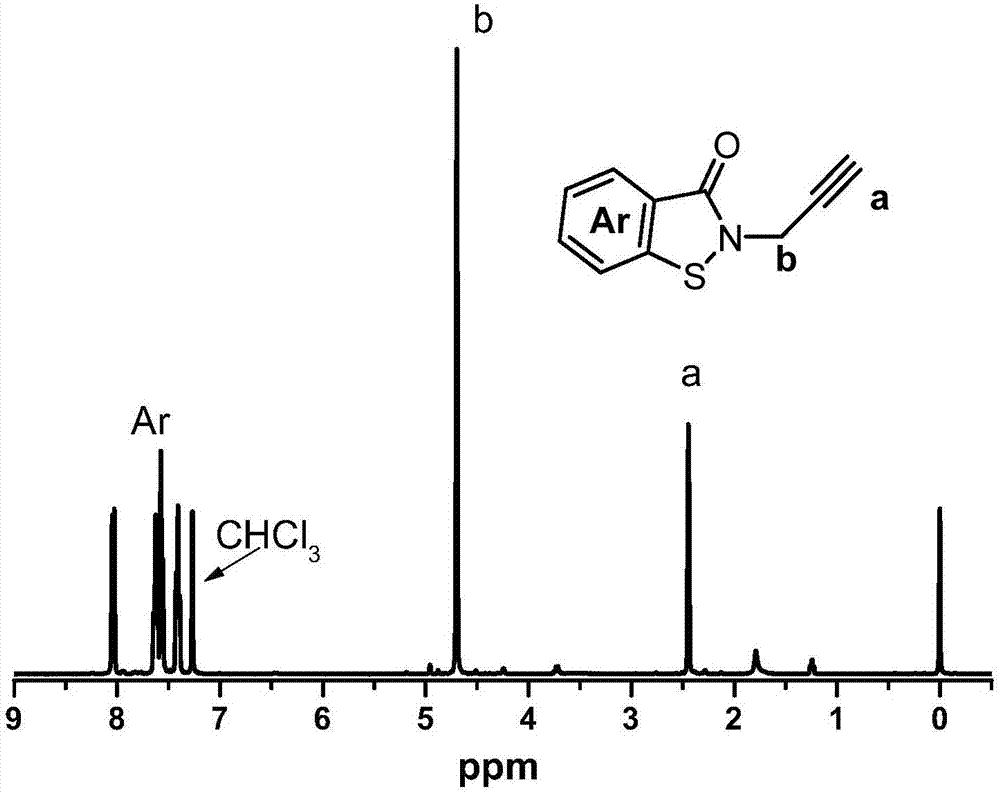

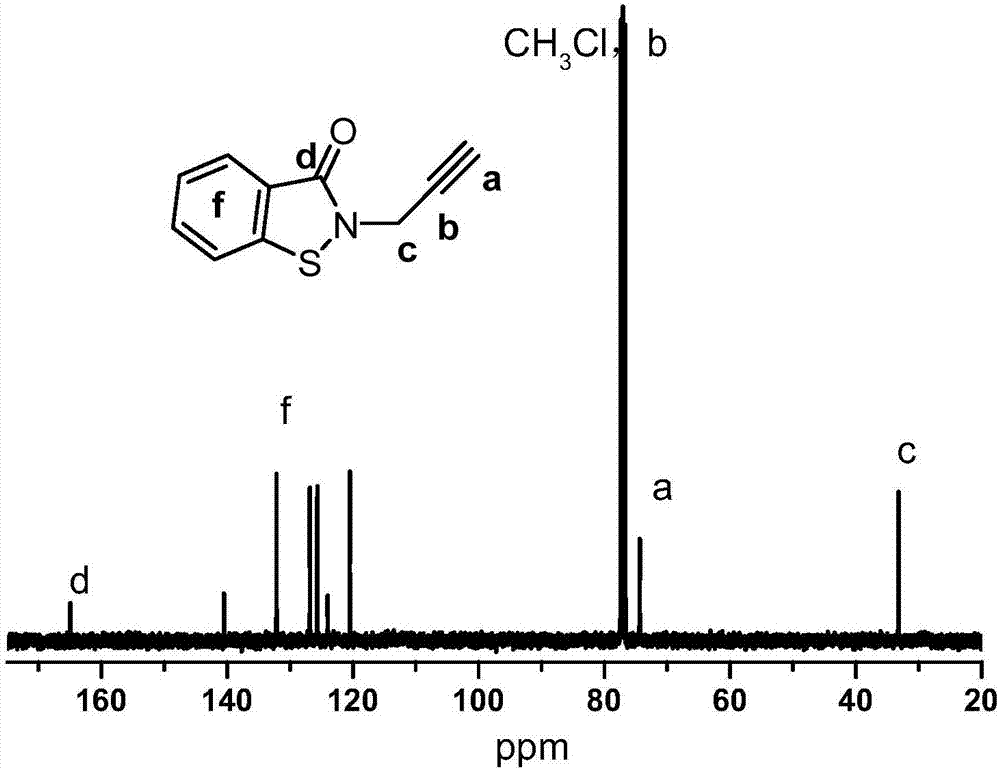

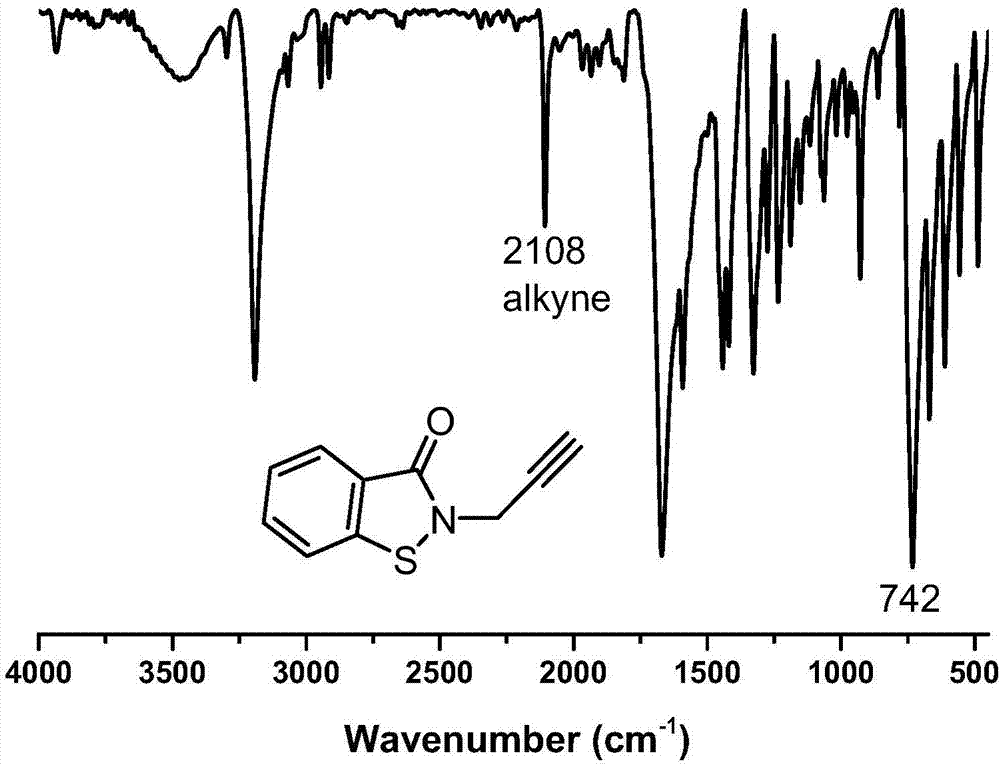

[0065] (1) Preparation of alkynyl-modified 1,2-benzisothiazolin-3-one (BIT-Al):

[0066] Add 10 g of BIT (66 mmol), appropriate amount of potassium carbonate and 50 ml of dry DMF into a 100 ml single-necked round bottom flask. Then, 7.87 g of propyne bromide (66 mmol) was slowly added dropwise at room temperature, and after the drop was completed, the reactant was continuously stirred at room temperature for 16-24 h. Then add an appropriate amount of saturated brine, and extract three times with ethyl acetate; combine the organic phases, wash three times with saturated brine, dry the organic phases with anhydrous magnesium sulfate, concentrate, and recrystallize in ethanol to obtain 7.61 g of a light yellow solid , the yield of alkynyl-modified 1,2-benzisothiazolin-3-one (BIT-Al) was about 61%.

[0067] (2) Preparation of polyurethane (PU-N) containing azide functional group 3 ):

[0068] Dehydrate the polyether diol PPG (Mn=1000) in vacuum for 1.5h at 100°C, drop to room t...

Embodiment 2

[0072] The difference between this embodiment and embodiment 1 is that step (3) prepares antibacterial polyurethane:

[0073] Under magnetic stirring, add 24g of the above PU-N to a 100ml three-necked bottle 3 solution and 20ml of water and DMF mixed solution containing BIT-Al (0.8g) (V DMF :V H2O =9:1). Then 2 ml of copper sulfate water-DMF solution (containing 0.02 g of copper sulfate pentahydrate) was added, the mixture was degassed with nitrogen for 20 minutes, 0.06 g of sodium ascorbate was added, and reacted at room temperature for 1 h. Then, take 5 g of the reactant solution into a polytetrafluoroethylene petri dish with a diameter of 4 cm, dry at 75° C. for 24 h, cool, and remove the film to obtain an antibacterial polyurethane film (PU-BIT2).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com