A fermented red dragon fruit wine, dragon fruit brandy and production method thereof

A technology of red heart dragon fruit and dragon fruit wine, which is applied in the field of fruit wine fermentation, and can solve problems such as stickiness, backward production technology of fruit brandy, and difficulty in filtering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

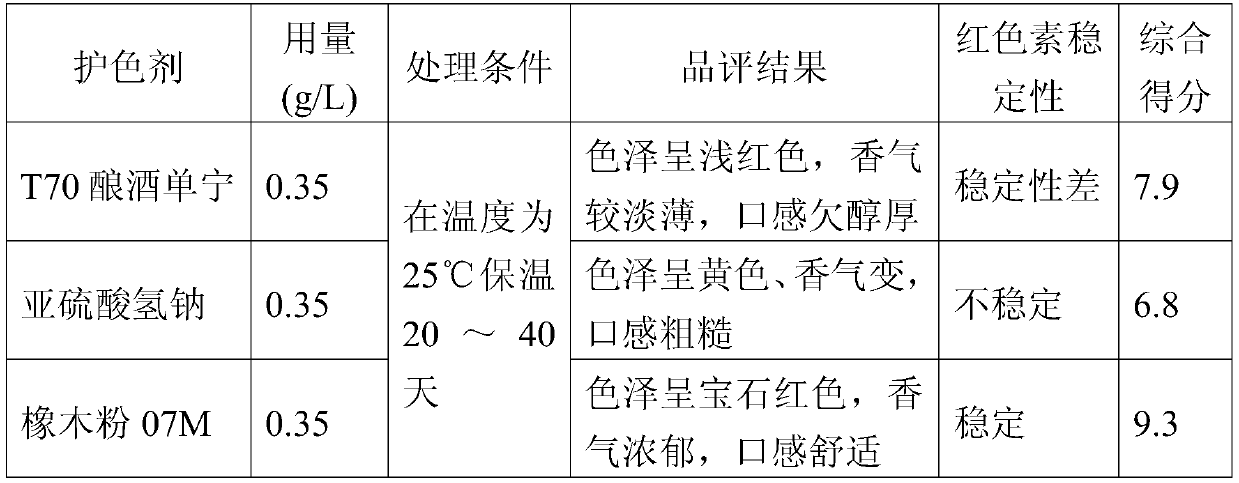

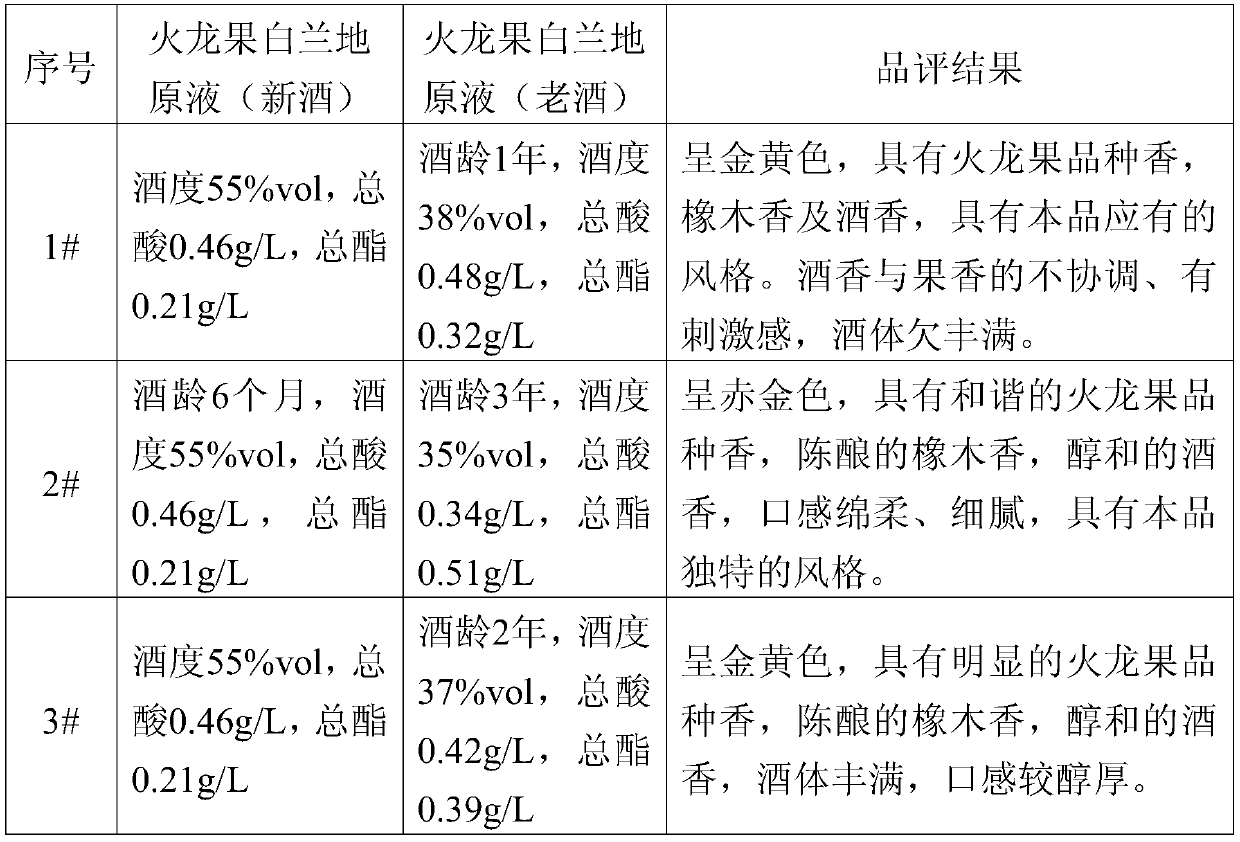

Method used

Image

Examples

Embodiment 1

[0085] (1) Selection of raw materials: red dragon fruit requires more than eight mature, physical and chemical indicators: total sugar 95 ~ 110g / L, total acid 2 ~ 4g / L. The red dragon fruit used for production must be fresh, free from rotten fruit, diseased fruit, and high juice yield;

[0086] (2) Solid-liquid enzymatic hydrolysis: first crush the selected, cleaned and sterilized red dragon fruit (whole fruit including pulp and peel) and then add solid pectinase Lallzyme CUVEE ROUGE TM (French Raman Group) carries out enzymolysis, and the addition amount of solid pectinase is 35mg / L to add according to final concentration in enzymolysis system; Enzymolysis condition is 19.0 ℃ of enzymolysis 4 hours; Then add 17mg / L ) liquid pectinase Pectinex BE3-L for enzymolysis; the enzymolysis condition is 8°C for 5.5 hours;

[0087] (3) Continuous low-temperature fermentation of macerated red: Add wine Saccharomyces cerevisiae LalvinBRL97 to the enzymatic hydrolyzate obtained in step (2...

Embodiment 2

[0100] (1) Selection of raw materials: red dragon fruit requires more than eight mature, physical and chemical indicators: total sugar 95 ~ 110g / L, total acid 2 ~ 4g / L. The red dragon fruit used for production must be fresh, free from rotten fruit, diseased fruit, and high juice yield;

[0101] (2) Solid-liquid enzymatic hydrolysis: first crush the selected, cleaned and sterilized red dragon fruit (whole fruit including pulp and peel) and then add solid pectinase Lallzyme CUVEE ROUGE TM (French Raman Group) carries out enzymolysis, and the addition amount of solid pectinase is added according to final concentration in enzymolysis system is 36mg / L; Enzymolysis condition is 20.0 ℃ of enzymolysis 5 hours; Then add 20mg / L ) liquid pectinase PectinexBE3-L for enzymolysis; the enzymolysis condition is 9.5°C for 6.3 hours;

[0102] (3) Continuous low-temperature fermentation of macerated red: Add wine Saccharomyces cerevisiae LalvinBRL97 to the enzymatic hydrolyzate obtained in step...

Embodiment 3

[0115] (1) Selection of raw materials: red dragon fruit requires more than eight mature, physical and chemical indicators: total sugar 95 ~ 110g / L, total acid 2 ~ 4g / L. The red dragon fruit used for production must be fresh, free from rotten fruit, diseased fruit, and high juice yield;

[0116] (2) Solid-liquid enzymatic hydrolysis: first crush the selected, cleaned and sterilized red dragon fruit (whole fruit including pulp and peel) and then add solid pectinase Lallzyme CUVEE ROUGE TM (French Raman Group) carries out enzymolysis, and the addition amount of solid pectinase is 37mg / L to add according to final concentration in enzymolysis system; Enzymolysis condition is 21.0 ℃ of enzymolysis 6 hours; Then add 23mg / L (final concentration ) Liquid pectinase PectinexBE3-L; the enzymolysis condition is 11.0°C for 7.0 hours;

[0117] (3) Continuous low-temperature fermentation of macerated red: Add wine Saccharomyces cerevisiae LalvinBRL97 to the enzymatic hydrolyzate obtained in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com