DMM2 preparation process and system

A DMM2 and process technology, which is applied in the field of preparation technology and system of polymethoxydimethyl ether dimer, namely DMM2, can solve the problems of low yield of DMM2, need to be repeatedly regenerated, cannot be separated, etc., and shorten the production process. , reduce investment and energy consumption, and solve difficult effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

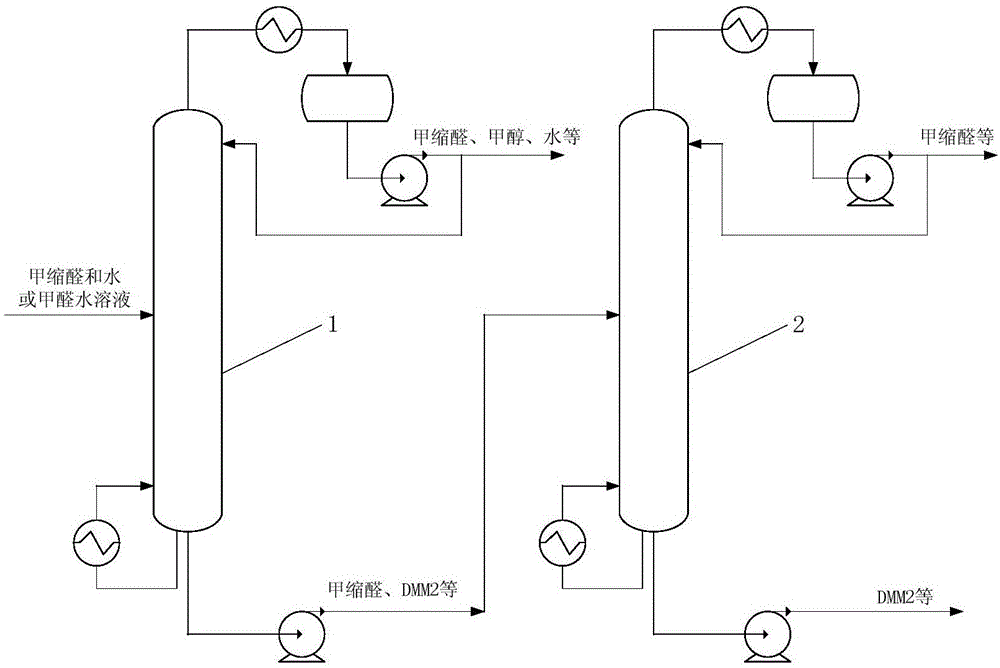

[0051] A process for preparing polyoxymethylene dimethyl ether dimer DMM2, adopting such as figure 1 The system structure shown includes the following:

[0052] The reaction equipment is a catalytic rectification tower 1, the reaction section in the tower is equipped with an appropriate amount of strongly acidic cation exchange resin, the rectification section and the stripping section in the tower are equipped with high-efficiency packing, and the reaction raw materials are sent to the In the middle part of the reaction section of the catalytic rectification tower, the pressure of the reaction section of the catalytic rectification tower is controlled to be 0.2MPaG, the temperature of the reaction section is controlled to be 75°C, and the reflux ratio of the catalytic rectification tower is controlled to be 5.0.

[0053] The reaction raw material is a mixture of methylal, methanol and water, wherein the mass fraction of each component is: 96.2% of methylal, 2.33% of methanol,...

Embodiment 2

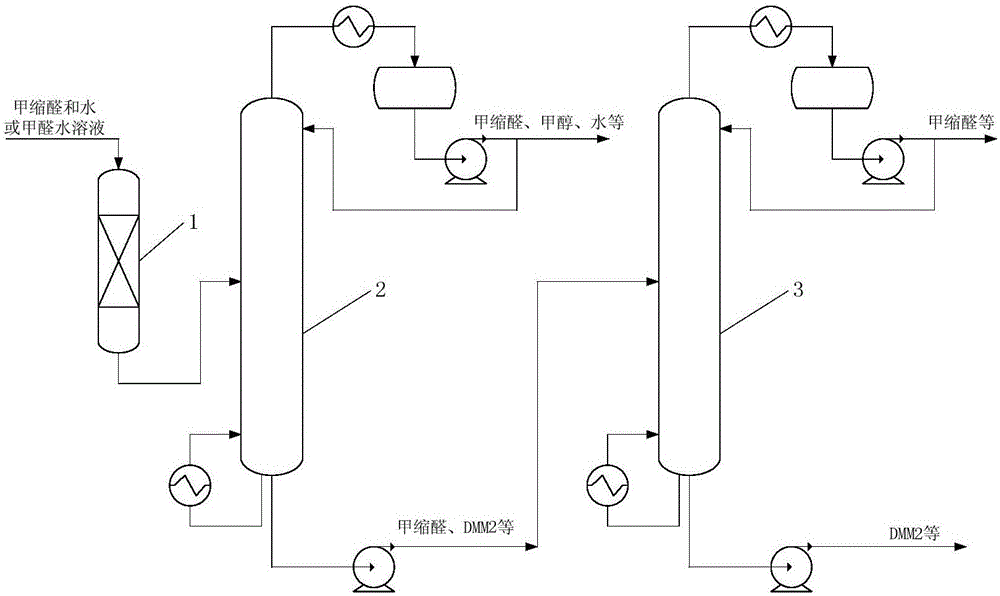

[0058] A process for preparing polyoxymethylene dimethyl ether dimer DMM2, adopting such as figure 2 The system structure shown includes the following:

[0059] The reaction equipment is a combination of a fixed bed reactor 1 and a catalytic rectification tower 2. The fixed bed reactor 1 is equipped with a strong acidic cation exchange resin, and the reaction section of the catalytic rectification tower 2 is equipped with a sufficient amount of strong acidic cation exchange resin. The rectification section and the stripping section are equipped with high-efficiency packing.

[0060] The reaction raw material is a mixture of methylal, methanol and formaldehyde aqueous solution, wherein the mass fraction of each component is: 90.41% of methylal, 1% of methanol, 5.38% of water, and 3.21% of formaldehyde.

[0061] After the above reaction raw materials are preheated to 120°C, they are sent to the top of the fixed-bed reactor by a metering pump at a speed of 25g / min. Under the ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com