A kind of titanium-containing silicon molecular sieve catalyst and its preparation method and application

A technology of titanium-silicon molecular sieves and catalysts, which is applied in molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of poor catalytic performance and deactivation of titanium-silicon molecular sieves, and achieve good activity and activity stability , energy saving and pollution reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0015] As mentioned above, the present invention provides a method for preparing a titanium-containing silicon molecular sieve catalyst. The method includes: (1) contacting the unloading agent with an organic compound to obtain a contacted product, and the organic compound is selected from sulfone and ketone And one or more of amides, the unloading agent is the unloading agent of the reaction device with titanium silicate molecular sieve as the active component of the catalyst; (2) in the presence of an aqueous solvent, mixing the contacted product alkali source After that, hydrothermal treatment is performed.

[0016] According to the method of the present invention, the purpose of the present invention can be achieved by following the aforementioned scheme. Organic compounds meeting the aforementioned requirements can be used in the present invention. For the present invention, the organic compounds are preferably sulfoxides, sulfones, alkanones and amides. One or more of.

[00...

Embodiment approach

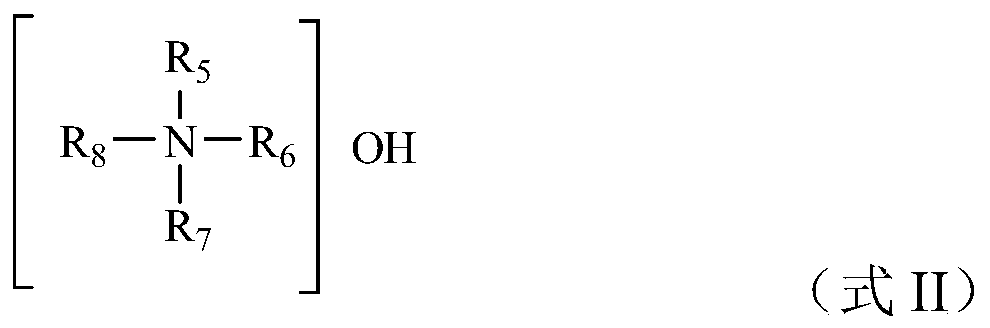

[0050] According to a preferred embodiment of the present invention, preferably the alkali source is ammonia, sodium hydroxide, potassium hydroxide, calcium hydroxide, lithium hydroxide, sodium carbonate, potassium carbonate, tetrapropylammonium hydroxide, tetraethyl One of ammonium hydroxide, tetramethylammonium hydroxide, tetrabutylammonium hydroxide, ethylamine, n-propylamine, n-butylamine, di-n-propylamine, butanediamine, hexamethylenediamine, monoethanolamine, diethanolamine and triethanolamine Or multiple. Various situations are, for example, a mixture of tetraethylammonium hydroxide and n-butylamine, a mixture of ethylenediamine and tetrapropylammonium hydroxide, a mixture of di-n-propylamine and tetrapropylammonium hydroxide, and tetraethylhydroxide. The mixture of ammonium and tetrapropylammonium hydroxide, and the mixture of hexamethylenediamine and tetrapropylammonium hydroxide can be used in the present invention, and there is no special requirement for the above-me...

Embodiment 1

[0066] Under normal pressure at 90℃, mix and contact dimethyl sulfoxide with the unloading agent (SH-1) for 5.5h, where the weight ratio of the unloading agent to dimethyl sulfoxide is 1:10, filter and wash with water Obtain the solid product after contact, and then dry it to constant weight at 180°C;

[0067] After mixing the dried solid and the aqueous ammonia solution at pH 10, hydrothermal treatment at 170℃ for 15h, the mass ratio of solid to ammonia is 50:1, filtering, washing and drying (120℃) to constant weight, and recovering molecular sieve A. The activity, relative crystallinity, and specific surface area of the micropores are shown in Table 1 (the activity determination method is consistent with the method and procedure for measuring the fresh agent, and the cyclohexanone conversion rate measured at the first hour is used as the activity).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com