Concrete water reducer and preparation method thereof

A concrete water-reducing agent and water-reducing agent technology, applied in the field of water-reducing agents, can solve the problems of large amount of water-reducing agent, poor plasticizing effect, poor water-reducing effect, etc. The effect of improving cohesion and workability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

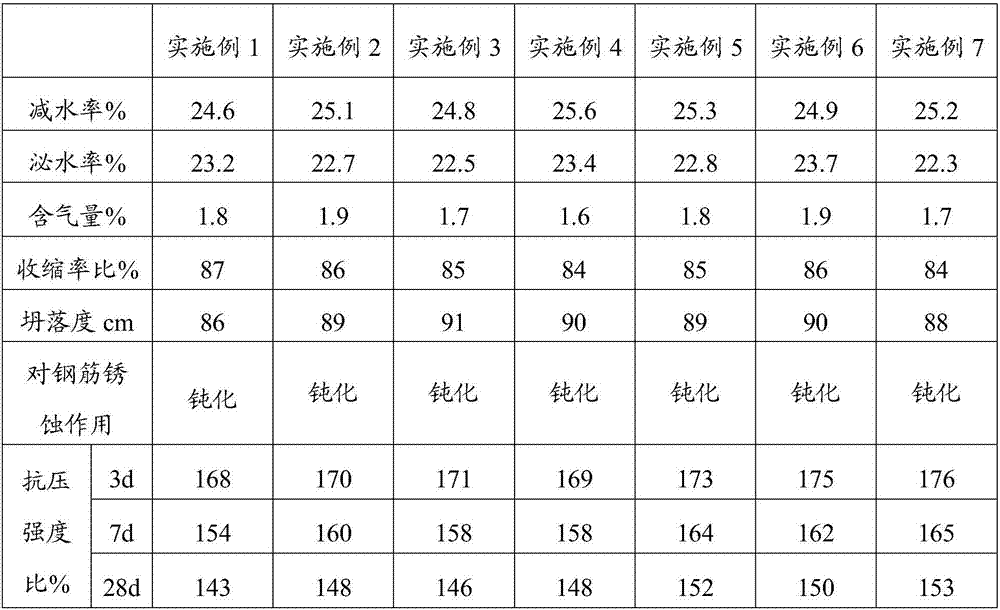

Examples

preparation example Construction

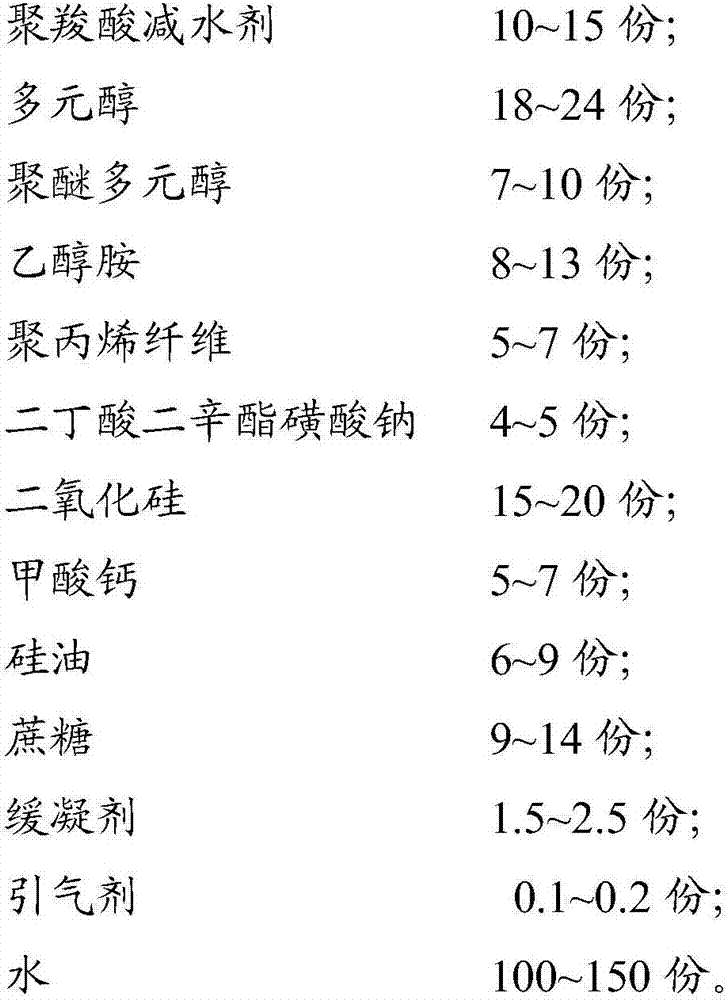

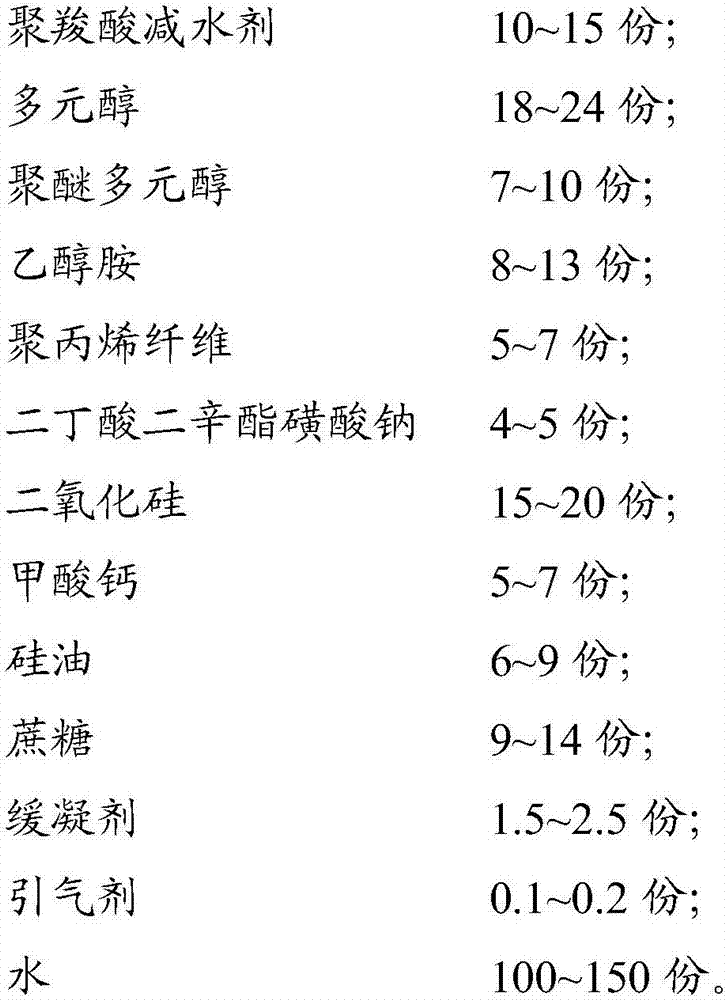

[0043] The present invention also provides a preparation method of concrete water reducing agent, comprising the following steps:

[0044] Weigh each raw material, add polycarboxylate water reducer, ethanolamine, and silicone oil into the polyol, stir at 400-600 r / min for 10-15 min, and add polyether polyol, polyether polyol and polyol under stirring at 100-200 r / min. Acrylic fiber, sodium dioctyl dibutyrate sulfonate, silicon dioxide, calcium formate, sucrose, retarder, air-entraining agent and water, fully ball-milled and cooled to obtain concrete water reducing agent.

[0045] Among them, polycarboxylate superplasticizer, polyol, polyether polyol, ethanolamine, polypropylene fiber, sodium dioctyl dibutyrate sulfonate, silicon dioxide, calcium formate, silicone oil, sucrose, retarder, air-entrained The agent and water are the same as above, and will not be repeated here.

[0046] In the above technical solution, the process is simple, the prepared waterproof coil material h...

Embodiment 1

[0049] The concrete water reducing agent includes the following raw materials in parts by weight:

[0050] 11 parts of acrylic polycarboxylate water reducer, 19 parts of ethylene glycol, 7.5 parts of polyoxypropylene glycol, 8 parts of triethanolamine, 5.5 parts of polypropylene fiber, 4.4 parts of sodium dioctyl dibutyrate sulfonate, 16 parts Silica, 5.8 parts of calcium formate, 6 parts of methyl ethoxy silicone oil, 11 parts of sucrose, 1.9 parts of citric acid, 0.14 parts of calcium lignosulfonate and 100 parts of water; the particle size of the silica is 200 nm.

[0051] The preparation method of concrete water reducing agent comprises the following steps:

[0052] Weigh each raw material according to the above-mentioned parts by weight, add acrylic polycarboxylate water reducer, triethanolamine and methyl ethoxy silicone oil into ethylene glycol, stir at 600r / min for 12min, and stir at 150r / min Add polyoxypropylene glycol, polypropylene fiber, sodium dioctyl dibutyrate ...

Embodiment 2

[0054] The concrete water reducing agent includes the following raw materials in parts by weight:

[0055] 10 parts of acrylic polycarboxylate water reducer, 23 parts of propylene glycol, 7 parts of polytetrahydrofuran diol, 9 parts of N-methyldiethanolamine, 5.8 parts of polypropylene fiber, 5 parts of sodium dioctyl dibutyrate sulfonate, 15 parts of parts of silicon dioxide, 5 parts of calcium formate, 7 parts of methyl vinyl silicone oil, 10 parts of sucrose, 1.5 parts of sugar calcium, 0.16 parts of rosin soap and 110 parts of water; the particle size of the silicon dioxide is 100-200 nm.

[0056] The preparation method of concrete water reducing agent comprises the following steps:

[0057] Weigh each raw material according to the above-mentioned parts by weight, add acrylic polycarboxylate water reducer, N-methyldiethanolamine, methyl vinyl silicone oil to propylene glycol, stir at 500r / min for 12min, and stir at 150r / min Add polytetrahydrofuran diol, polypropylene fibe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com