Preparation method of rice straw-acrylic acid-acrylamide graft copolymer

A technology of graft copolymer and acrylamide, which is applied in the field of preparation of rice straw-acrylic acid-acrylamide graft copolymer, which can solve the problems of low ratio of three-dimensional network structure, weak controlled release of fertilizer, and few grafting sites, etc. problem, to achieve the effect of no chemical reagent residue, high degree of cross-linking, and uniform grafting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1: Preparation of a kind of rice straw-acrylic acid-acrylamide graft copolymer

[0034] 1.1 Main raw materials, reagents and instruments

[0035] Rice straw (Hefei); acrylic acid (AA, analytical grade); acrylamide (AM, analytical grade); sodium hydroxide (NaOH, analytical grade); 0.9% NaCl solution; urea (Urea); Base bisacrylamide (analytical pure), FeSO4 • 7H2O (analytical pure).

[0036] 60Co-γ irradiation source, Hefei (National) Forestry Irradiation Center, activity 200,000 Ci, single grid shape, absorption metering rate is calibrated by dichromate dosimeter; SYC-15 constant temperature water bath (Hebei, Run United Technology Co., Ltd.); WK-150A Superfine Grinder (Jinan, Dawei Machinery Co., Ltd.); 8700 Fourier Transform Infrared Spectrometer (FTIR, America, ThermoNicolet Company); D / X-2800 X-ray Powder diffractometer (XRD, Dandong, Haoyuan Instrument Co., Ltd.).

[0037] 1.2 Preparation of rice straw-acrylic acid-acrylamide graft copolymer

[0038] ...

Embodiment 2

[0058] Embodiment 2: Results and analysis

[0059] 2.1. XRD analysis

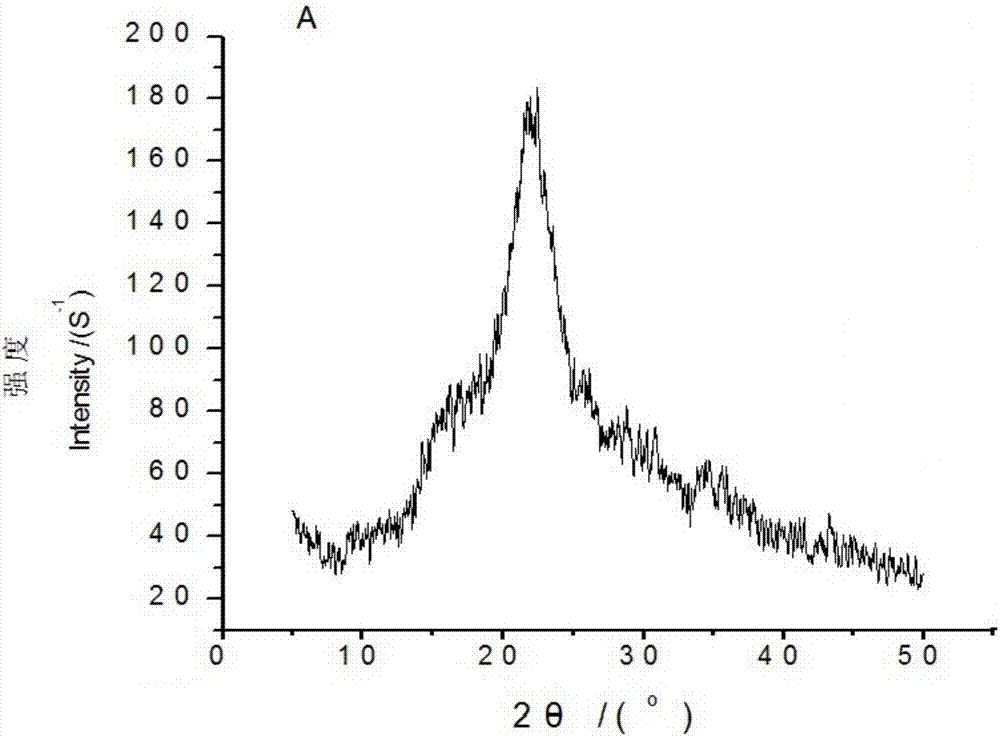

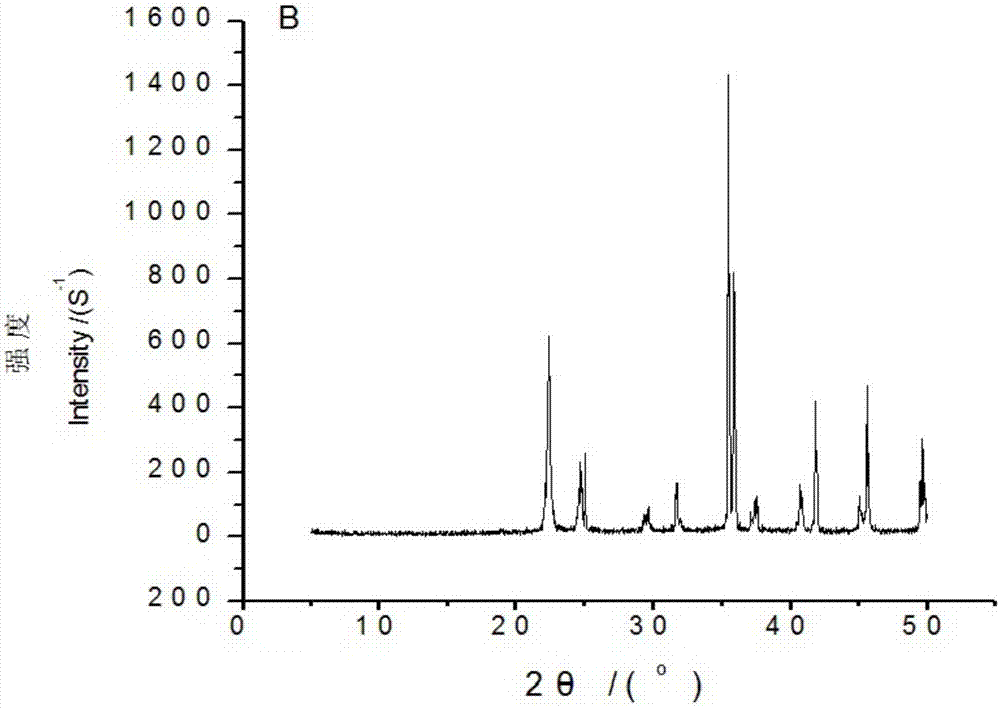

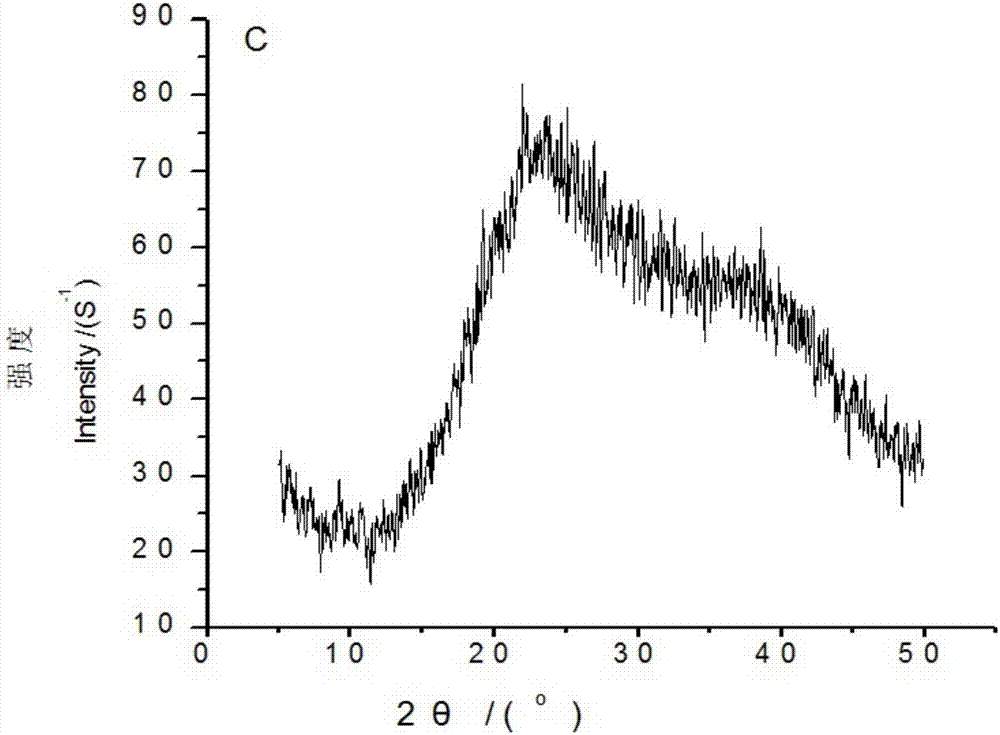

[0060] In the range of 2θ angles, figure 1 The straw powder without decrystallization has a relatively narrow diffraction peak at 22.38, indicating that the straw powder without decrystallization contains a lot of hydrogen bonds. Figure 2 shows the straw powder treated with NaOH / Urea aqueous solution. A wider dispersion peak was formed in the range of 2θ angle, which indicated that the regular crystallization area between the macromolecular chains in the straw was destroyed during the decrystallization treatment, and the amorphous area increased. image 3 It is the XRD pattern of urea, showing that urea is crystal, Figure 4 It is the XRD pattern of the graft copolymer, and the width of the dispersion peak further increases, indicating that after the straw is irradiated and grafted and copolymerized in the solution state, the crystalline region becomes an amorphous region. It shows that the macromolecu...

Embodiment 3

[0078] Example 3: Preparation of another rice straw-acrylic acid-acrylamide graft copolymer

[0079] Measure 100ml of deionized water, take 3ml of AA, add 4g of AM powder, measure 0.5g of the above-mentioned decrystallized straw powder in a beaker, stir well, add 0.2g of polymerization inhibitor FeSO 4 7H2O, add 0.2g N,N'-methylenebisacrylamide at the same time, stir well, and send it to the irradiation workshop;

[0080] Other steps are identical with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com