A kind of preparation method of conjugated diene compound

A conjugated diene and compound technology, which is applied in the field of fine chemicals and related chemistry, can solve problems such as high reaction temperature, and achieve the effects of easy availability of raw materials, cheap raw materials and mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Example 1: Synthesis of 2,3-diphenyl-1,3-dibutene

[0038] In a 25mL reactor, add p-toluenesulfonic acid (0.029g, 0.15mmol), pivalic acid (0.087g, 0.85mmol), zinc powder (0.033g, 0.5mmol), tetrakis(triphenylphosphine) palladium (0.023 g, 0.02mmol), nitrogen replacement 3 times, add anhydrous dichloromethane 3mL, add phenylacetylene (0.051g, 0.5mmol) under stirring, stir at 25°C for 24h. Column chromatography (silica gel, 200-300 mesh; developer, petroleum ether) obtained 0.038 g of 2,3-diphenyl-1,3-dibutene with a yield of 73%.

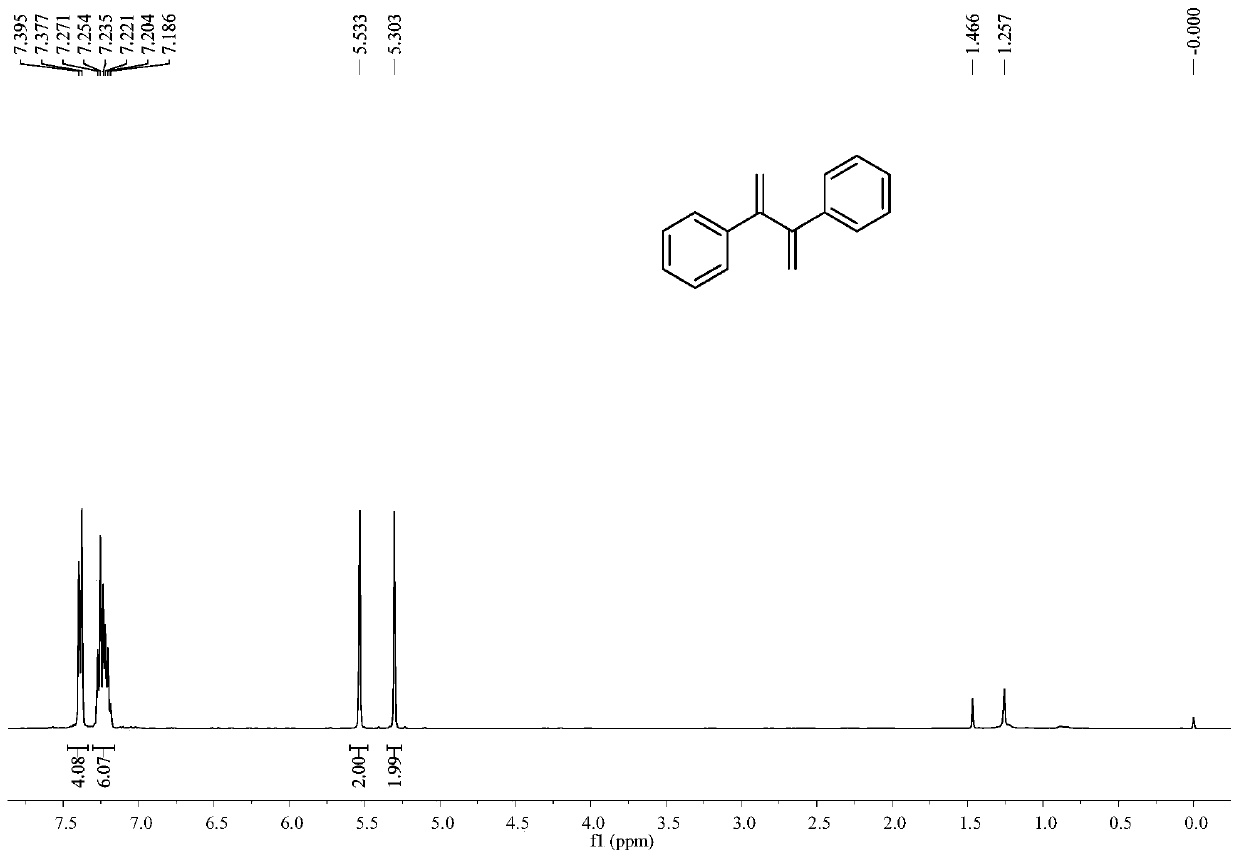

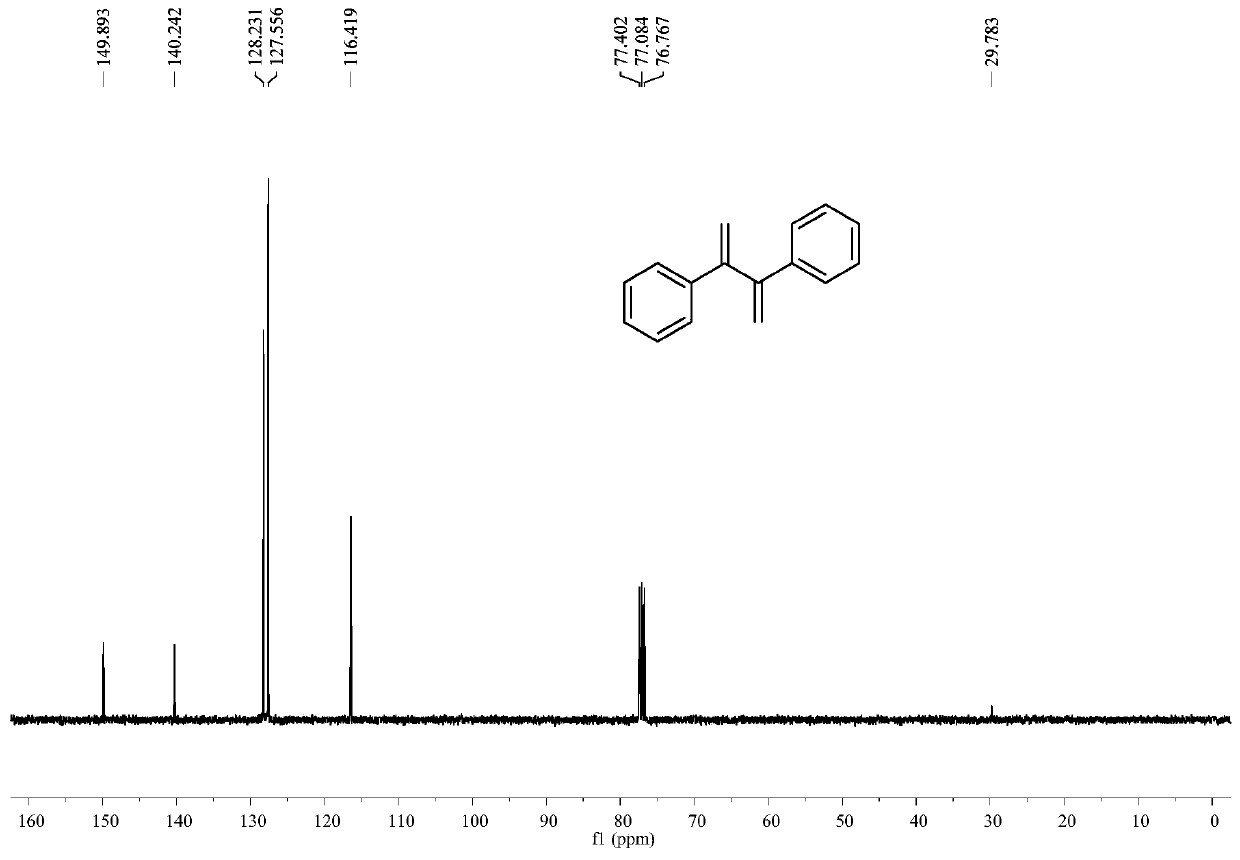

[0039] 2,3-Diphenyl-1,3-dibutene

[0040] colorless crystals; 1 H NMR (CDCl 3 ,400MHz)δ7.38-7.40(m,4H),7.19-7.27(m,6H),5.53(s,2H),5.30(s,2H); 13 C NMR (CDCl 3 ,100MHz)δ149.9,140.2,128.2,127.6,116.4ppm; MS(EI)m / z=207,206,191,178,128,115,91.

Embodiment 2

[0041] Example 2: Synthesis of 2,3-bis(4-methylphenyl)-1,3-dibutene

[0042] The operation was the same as in Example 1, and 0.049 g of 2,3-bis(4-methylphenyl)-1,3-dibutene was obtained by reacting 4-methylphenylacetylene, with a yield of 83%.

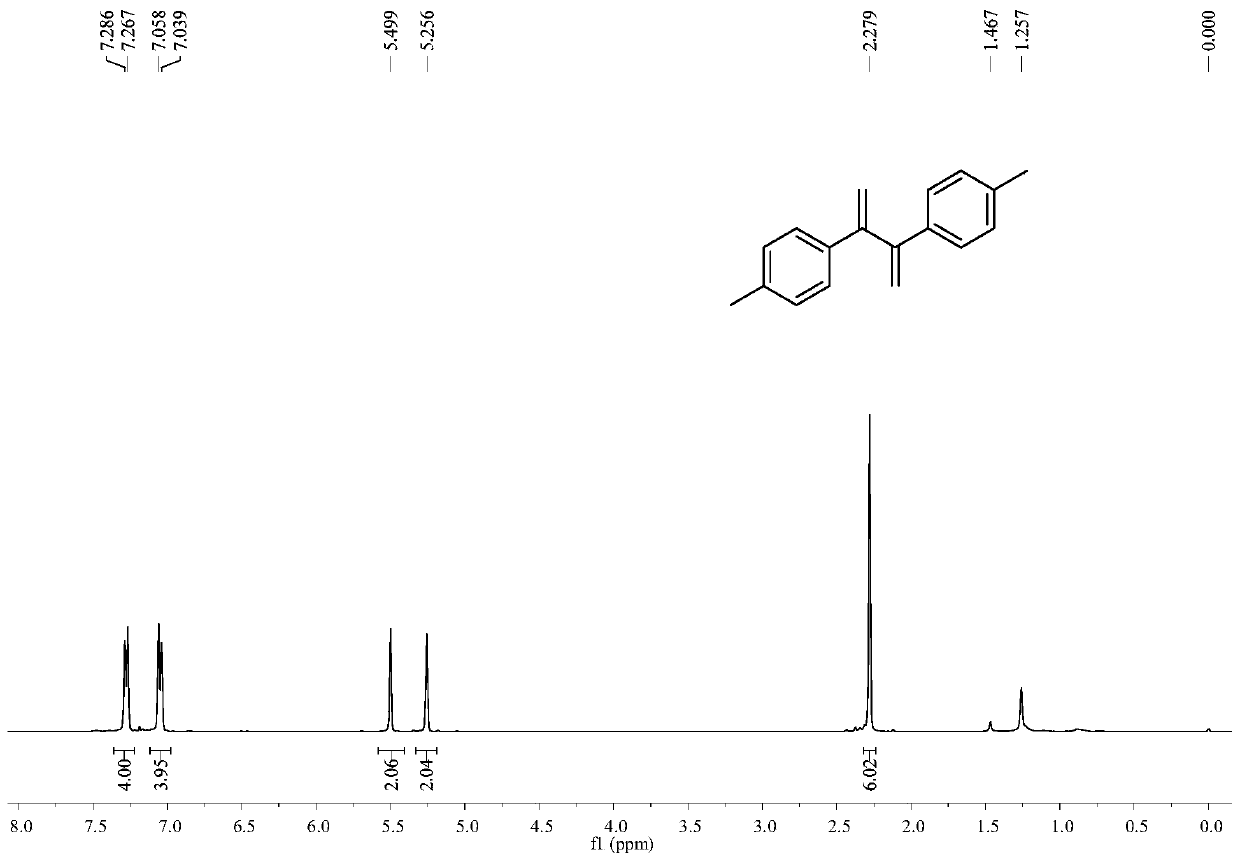

[0043] 2,3-bis(4-methylphenyl)-1,3-dibutene

[0044] white solid; 1 H NMR (CDCl 3 ,400MHz)δ7.28(d,J=8.0Hz,4H),7.05(d,J=8.0Hz,4H),5.50(s,2H),5.26(s,2H),2.28(s,6H); 13 C NMR (CDCl 3 ,100MHz)δ149.8,137.4,137.2,128.9,127.3,115.4,21.2ppm; MS(EI)m / z=235,234,219,204,128,115,91

Embodiment 3

[0045] Example 3: Synthesis of 2,3-bis(4-methoxyphenyl)-1,3-dibutene

[0046] The operation was the same as in Example 1, and 0.060 g of 2,3-bis(4-methoxyphenyl)-1,3-dibutene was obtained from the reaction of 4-methoxyphenylacetylene, with a yield of 90%.

[0047] 2,3-bis(4-methoxyphenyl)-1,3-dibutene

[0048] white solid; 1 H NMR (CDCl 3 ,400MHz)δ7.31(d,J=8.0Hz,4H),6.78(d,J=8.0Hz,4H),5.47(s,2H),5.23(s,2H),3.74(s,6H); 13 C NMR (CDCl 3 ,100MHz)δ159.1,149.4,132.7,128.5,114.3,113.6,55.2ppm; MS(EI)m / z=267,266,251,235,121

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com