Extreme pressure wear-resistant and easily disperse additive for copper wire drawing oil, preparation method and application

A technology of extreme pressure anti-wear and copper wire drawing oil, which is applied in the petroleum industry and lubricating compositions, etc. It can solve the problems of affecting the performance of the use, the anti-wear powder is difficult to dissolve in oil or water, and is easy to precipitate and stratify. It is not easy to achieve Oxidative discoloration, good compatibility, and not easy to precipitate and stratify

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Boric acid 19%

[0022] No. 120 mineral spirits 20%

[0023] Overbase Sulfonate Sodium Salt Extreme Pressure Agent 45%

[0024] Monosuccinimide 3%

[0025] Triphenyl Phosphate 5%

[0026] Add accurately measured boric acid, potassium hydroxide, No. 120 solvent oil, and high alkali value sulfonic acid sodium salt extreme pressure agent into the blending kettle, heat to 100 degrees and stir for 2 hours to form a product with good extreme pressure, anti-wear and friction-reducing properties. , Oxidation stability and excellent rust and corrosion resistance, non-corrosive to copper at high temperature and non-toxic and tasteless borate. Then add monosuccinimide and triphenyl phosphate, and stir thoroughly for 30 minutes to form a clear transparent liquid to obtain an extreme pressure, anti-wear and easy-to-disperse additive.

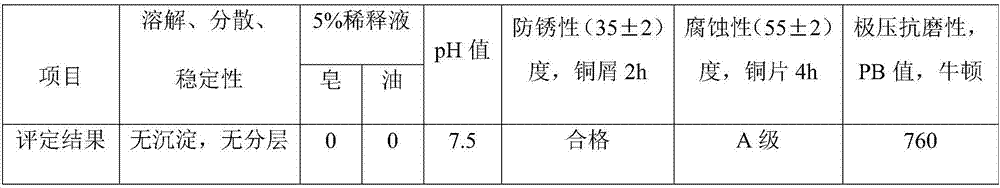

[0027] The additive and the base oil minus the second-line dewaxed oil, the emulsifier sodium petroleum sulfonat...

Embodiment 2

[0031] Boric acid 23%

[0033] Jet fuel 15%

[0034] High base number sulfonate calcium salt extreme pressure agent 41%

[0035] Disuccinimide 5%

[0036] Tricresyl Phosphate 3%

[0037] Add accurately measured boride, sodium hydroxide, jet fuel, high alkali value sulfonate calcium salt extreme pressure agent into the blending kettle, heat to 100 degrees and stir for 2 hours to form a product with good extreme pressure anti-wear and anti-friction properties, Oxidation stable and excellent rust and corrosion resistance, non-corrosive to copper at high temperatures, non-toxic and odorless borate. Then add bis-succinimide and tricresyl phosphate, and stir thoroughly for 30 minutes to form a clear liquid to obtain an extreme-pressure, anti-wear and easy-to-disperse additive.

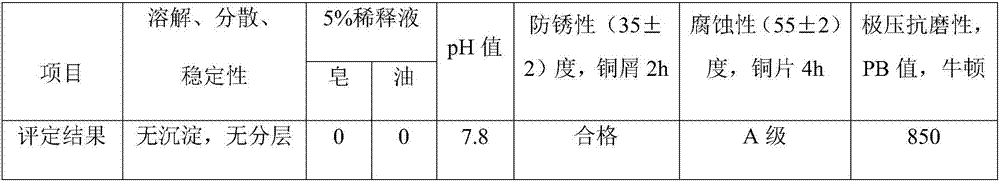

[0038] Prepare the additive and base oil minus second-line dewaxed oil, emulsifier sodium petroleum sulfonate and preservative benzotriazole to prepare copper drawing oil a...

Embodiment 3

[0042] Boric acid 15%

[0044] Jet fuel 19%

[0045] High base value sodium sulfonate extreme pressure agent 50%

[0046] Monosuccinimide 7%

[0047] Tricresyl Phosphate 3%

[0048] Add accurately measured boric acid, potassium hydroxide, aviation kerosene, high alkali value sulfonic acid sodium salt extreme pressure agent into the blending kettle, heat to 100 degrees and stir for 2 hours to form a good extreme pressure anti-wear and anti-friction, oxidation Stability and excellent rust and corrosion resistance, non-corrosive to copper at high temperature, non-toxic and odorless borate. Then add monosuccinimide and tricresyl phosphate, and stir thoroughly for 30 minutes to form a clear transparent liquid to obtain an extreme pressure, anti-wear and easy-to-disperse additive.

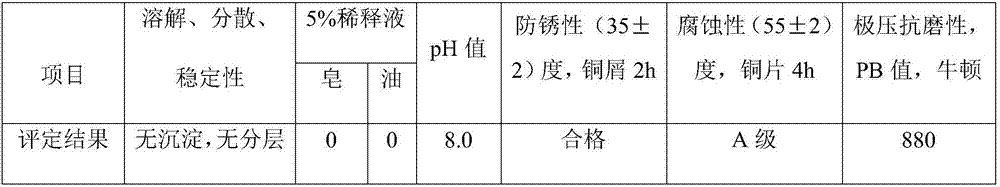

[0049] Prepare the additive and base oil minus second-line dewaxed oil, emulsifier sodium petroleum sulfonate and preservative benzotriazole to prepare copper drawing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com