Microcystin-lr Molecularly Imprinted Photoelectrochemical Sensor and Its Preparation and Application

A technology of microcystin and photoelectrochemistry, applied in the direction of material electrochemical variables, scientific instruments, instruments, etc., can solve the problems of inability to achieve online detection, low sensitivity, high cost, etc., and achieve simple and fast preparation methods and anti-interference ability Strong, low-cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

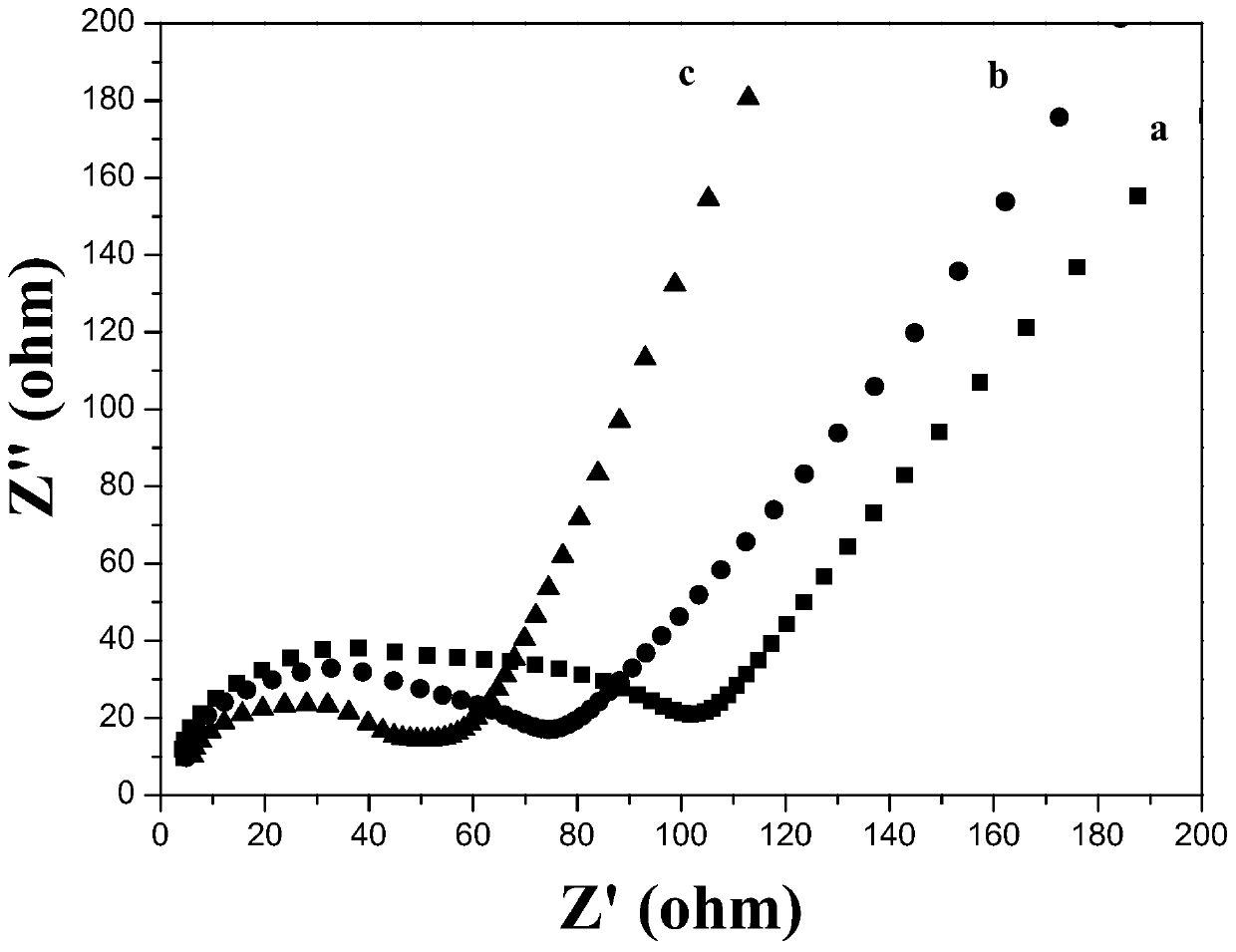

[0040] A visible light-driven Cu 2 Preparation of microcystin-LR molecularly imprinted photoelectrochemical sensors of O / PPy composites:

[0041] (1)Cu 2 Preparation of O photoelectric materials: the Cu 2 SO 4 solution with CH 3 CH(OH)COOH solution and a certain amount of PVP according to the molar ratio Cu 2 SO 4 :CH 3 Mix CH(OH)COOH 1:5:0.1 evenly, stir at room temperature for 2 hours, adjust the pH to 8-10 with NaOH solution, use ITO conductive glass as the working electrode, platinum sheet as the counter electrode, and Ag / AgCl as the reference Electrodes were deposited at a constant potential of -0.3V for 150s on a CHI660e workstation at 60°C, and then deposited at a constant potential of -0.2V for 700s. Finally, the electrodeposited Cu 2 The ITO conductive glass of the O photoelectric material is respectively placed in a certain amount of acetone, ethanol, and deionized water for 10 to 20 minutes of ultrasonication, and then placed in a blast drying oven at 40°C to...

Embodiment 2

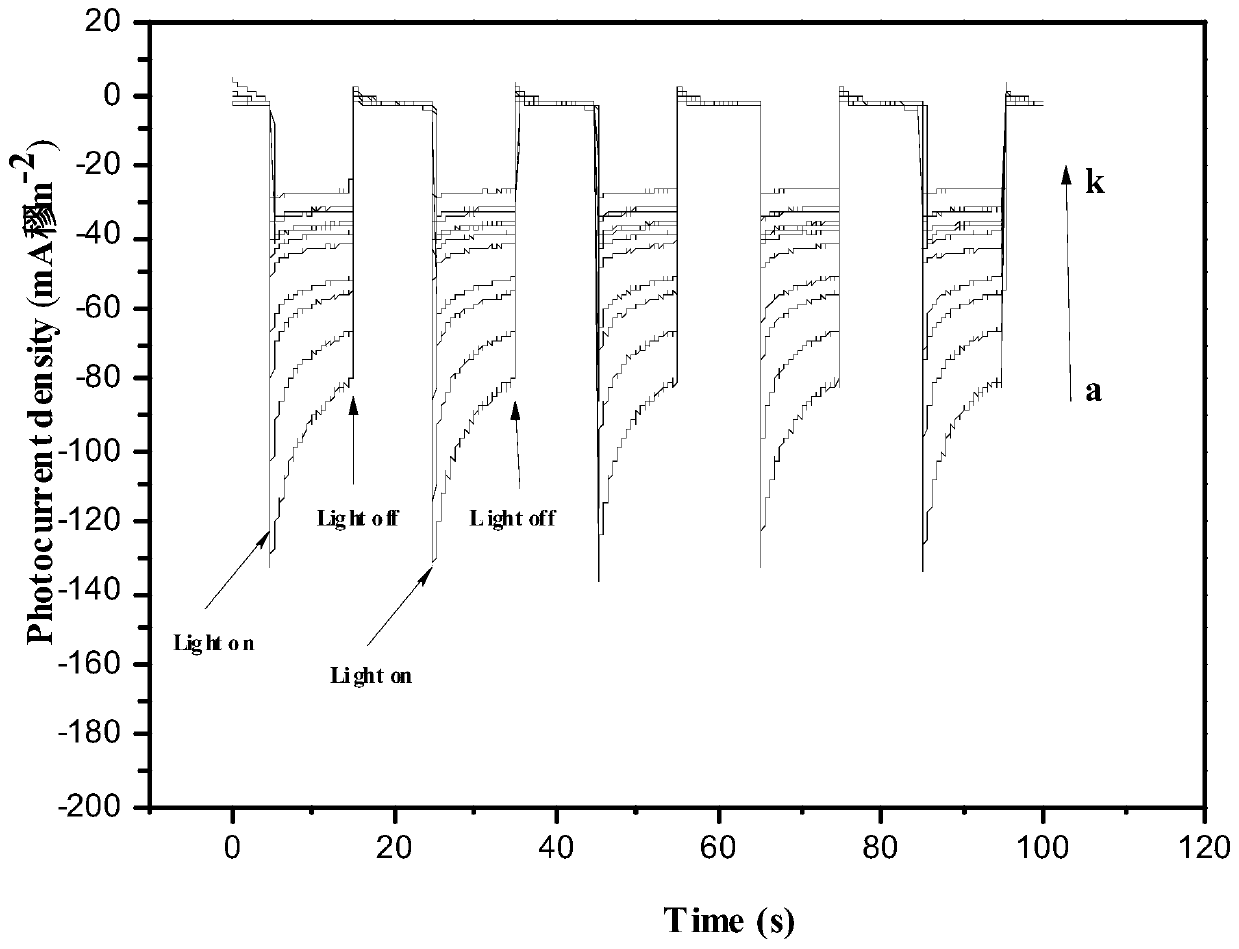

[0046] Visible light driven Cu 2 Microcystin-LR Molecularly Imprinted Photoelectrochemical Sensor of O / PPy Composite Material Rapid Detection Method of Microcystin-LR:

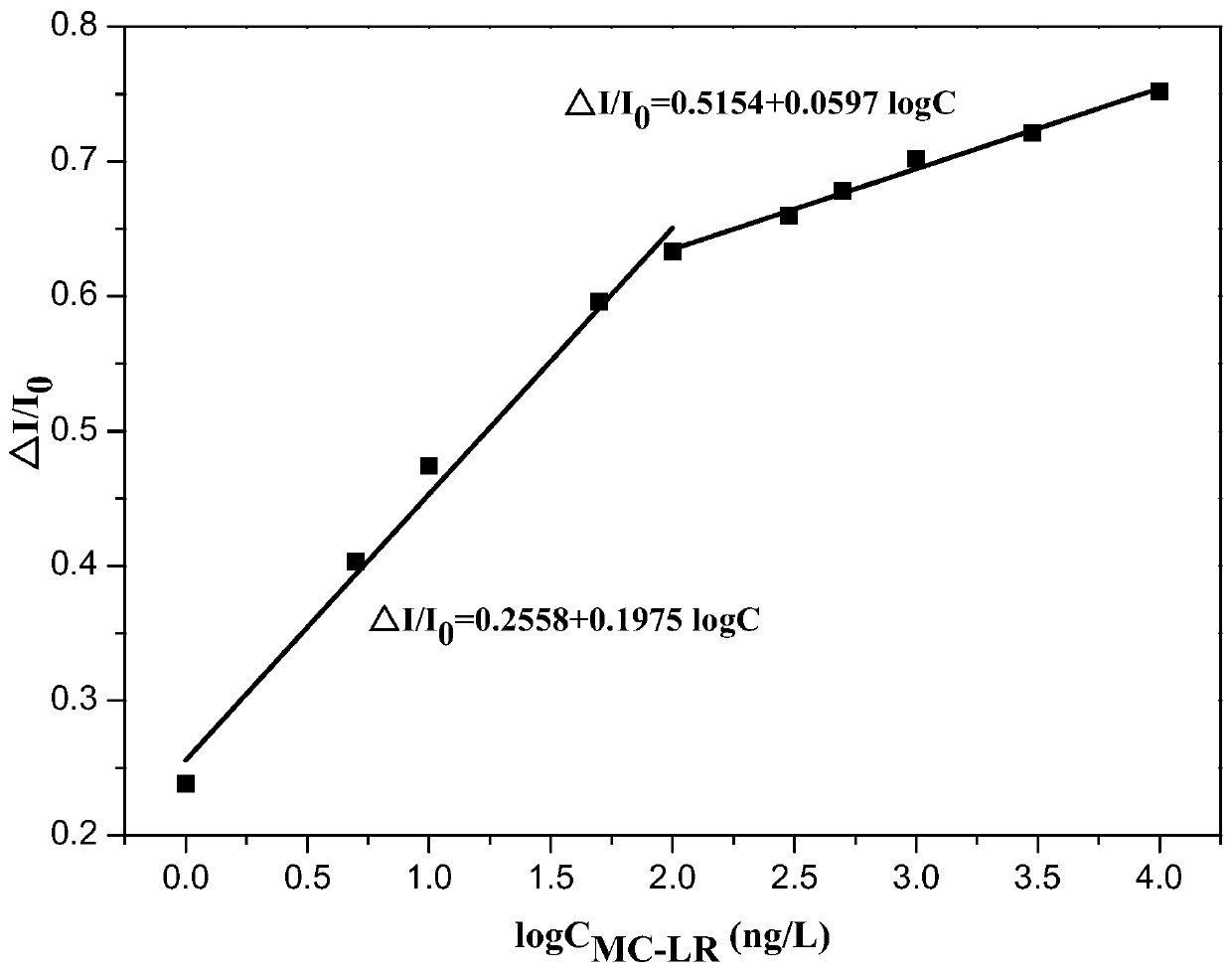

[0047] (1) Draw a standard curve: use PBS phosphate buffer solution with a pH of 7.2 to 7.4 to configure a series of standard solutions of microcystin-LR, and use the template-removing ITO conductive glass prepared in Example 1 as a work Electrodes, with platinum as the counter electrode, Ag / AgCl as the reference electrode, and visible light as the excitation light source, using i-t technology on the CHI660e electrochemical workstation, adding a bias of -0.2V, in order from low to high concentration Different photocurrents were obtained by detection, and finally a linear relationship was established between the photocurrent density and the concentration of microcystin-LR, and a standard curve was drawn.

[0048] (2) Microcystin-LR of unknown solubility is also configured in PBS phosphate buffer solution with ...

Embodiment 3

[0056] A visible light-driven Cu 2 Preparation of microcystin-LR molecularly imprinted photoelectrochemical sensors of O / PPy composites:

[0057] (1)Cu 2 Preparation of O photoelectric materials: the Cu 2 SO 4 solution with CH 3 CH(OH)COOH solution and a certain amount of PVP according to the molar ratio Cu 2 SO 4 :CH 3 CH(OH)COOH was uniformly mixed at a ratio of 1:5:5, stirred at room temperature for 2 hours, adjusted to pH 8-10 with a certain concentration of NaOH solution, using ITO conductive glass as the working electrode, platinum sheet as the counter electrode, Ag / AgCl As a reference electrode, under the condition of 55 ~ 65 ° C, on the CHI660e workstation, firstly electrodeposited at -0.3V potential constant potential for 100 ~ 200s, then at -0.2V potential constant potential for 600 ~ 800s, and finally electrodeposited Cu 2 The ITO conductive glass of the O photoelectric material is respectively placed in a certain amount of acetone, ethanol, and deionized wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com