Preparation method of lithium-ion battery negative electrode molybdenum disulfide and application thereof

A lithium-ion battery, molybdenum disulfide technology, applied in electrode manufacturing, battery electrodes, secondary batteries, etc., can solve problems such as reducing the efficiency of molybdenum disulfide, and achieve the effects of short time, multiple electron propagation channels, and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

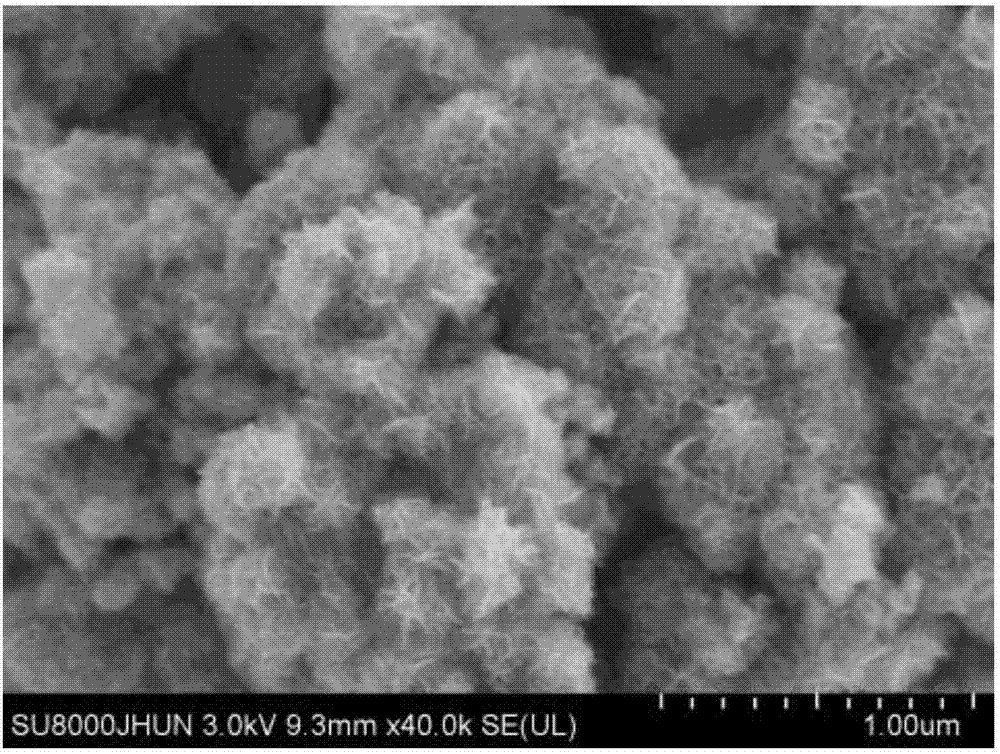

[0040] (1) Add 15 mL of deionized water to 0.3 g of sodium molybdate dihydrate and 0.6 g of thiourea. After the dissolution is complete, add 45 mL of diethylene glycol quickly, and stir vigorously in a water bath at 70°C until a homogeneous mixed solution is formed. Then, the mixed solution was put into a 100mL hydrothermal reactor, and the hydrothermal reaction was carried out at 200° C. for 24 hours;

[0041] (2) the above-mentioned hydrothermal reaction product is taken out and centrifuged, after removing the liquid part, centrifugal cleaning with deionized water and ethanol is used for 2 to 3 times, vacuum drying at 70 ° C for 12 hours, then in argon-hydrogen mixed gas (argon and hydrogen gas) A volume ratio of 95:5) was calcined at 400° C. for 2 hours to obtain molybdenum disulfide, a negative electrode for lithium ion batteries.

Embodiment 2

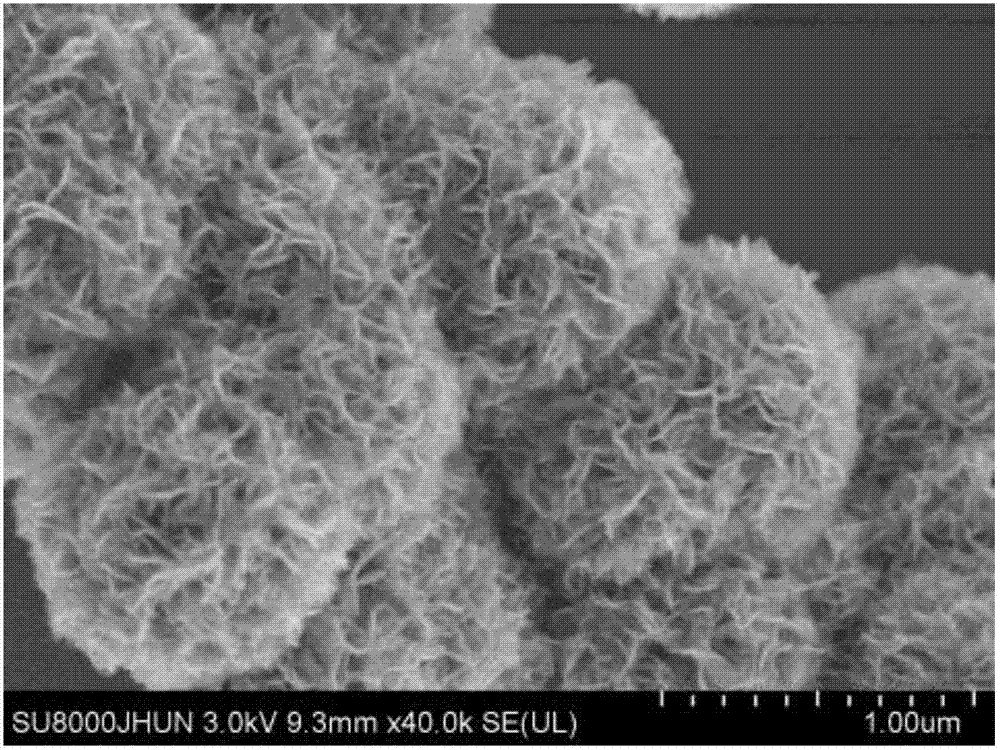

[0043] (1) Add 25 mL of deionized water to 0.3 g of sodium molybdate dihydrate and 0.6 g of thiourea, quickly add 35 mL of diethylene glycol after the dissolution is complete, and stir vigorously in a 70°C water bath until a homogeneous mixed solution is formed. Then, the mixed solution was put into a 100 mL hydrothermal reactor, and the hydrothermal reaction was carried out at 200° C. for 24 hours.

[0044] (2) the above-mentioned hydrothermal reaction product is taken out and centrifuged, after removing the liquid part, centrifugal cleaning with deionized water and ethanol is used for 2 to 3 times, vacuum drying at 70 ° C for 12 hours, then in argon-hydrogen mixed gas (argon and hydrogen gas) A volume ratio of 95:5) was calcined at 400° C. for 2 hours to obtain molybdenum disulfide, a negative electrode for lithium ion batteries.

Embodiment 3

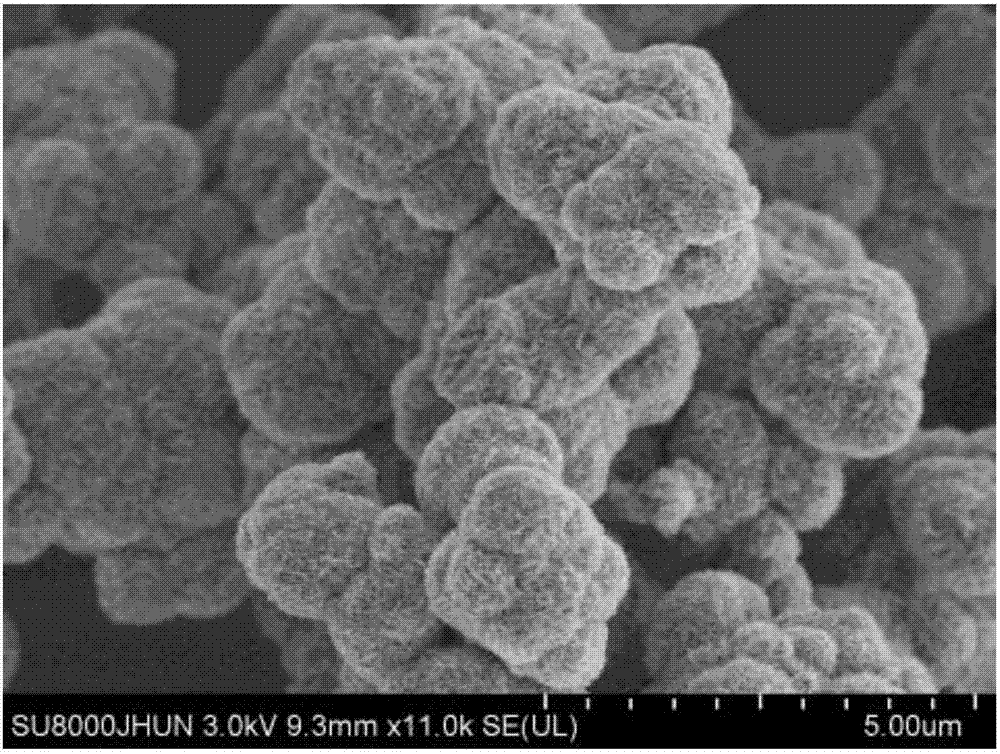

[0046] (1) Add 30 mL of deionized water to 0.3 g of sodium molybdate dihydrate and 0.6 g of thiourea, quickly add 30 mL of diethylene glycol after complete dissolution, and stir vigorously in a 70°C water bath until a homogeneous mixed solution is formed. Then, the mixed solution was put into a 100 mL hydrothermal reactor, and the hydrothermal reaction was carried out at 200° C. for 24 hours.

[0047](2) the above-mentioned hydrothermal reaction product is taken out and centrifuged, after removing the liquid part, centrifugal cleaning with deionized water and ethanol is used for 2 to 3 times, vacuum drying at 70 ° C for 12 hours, then in argon-hydrogen mixed gas (argon and hydrogen gas) A volume ratio of 95:5) was calcined at 400° C. for 2 hours to obtain molybdenum disulfide, a negative electrode for lithium ion batteries.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com