Layered double hydroxide composite nano-filtration membrane and preparation method thereof

A layered bimetallic and composite nanofiltration membrane technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problem of poor bonding between the surface layer and the base membrane, which affects the performance, uniformity and stability of the composite membrane Insufficient water resistance and other problems, to achieve good hydrophilicity, easy operation, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

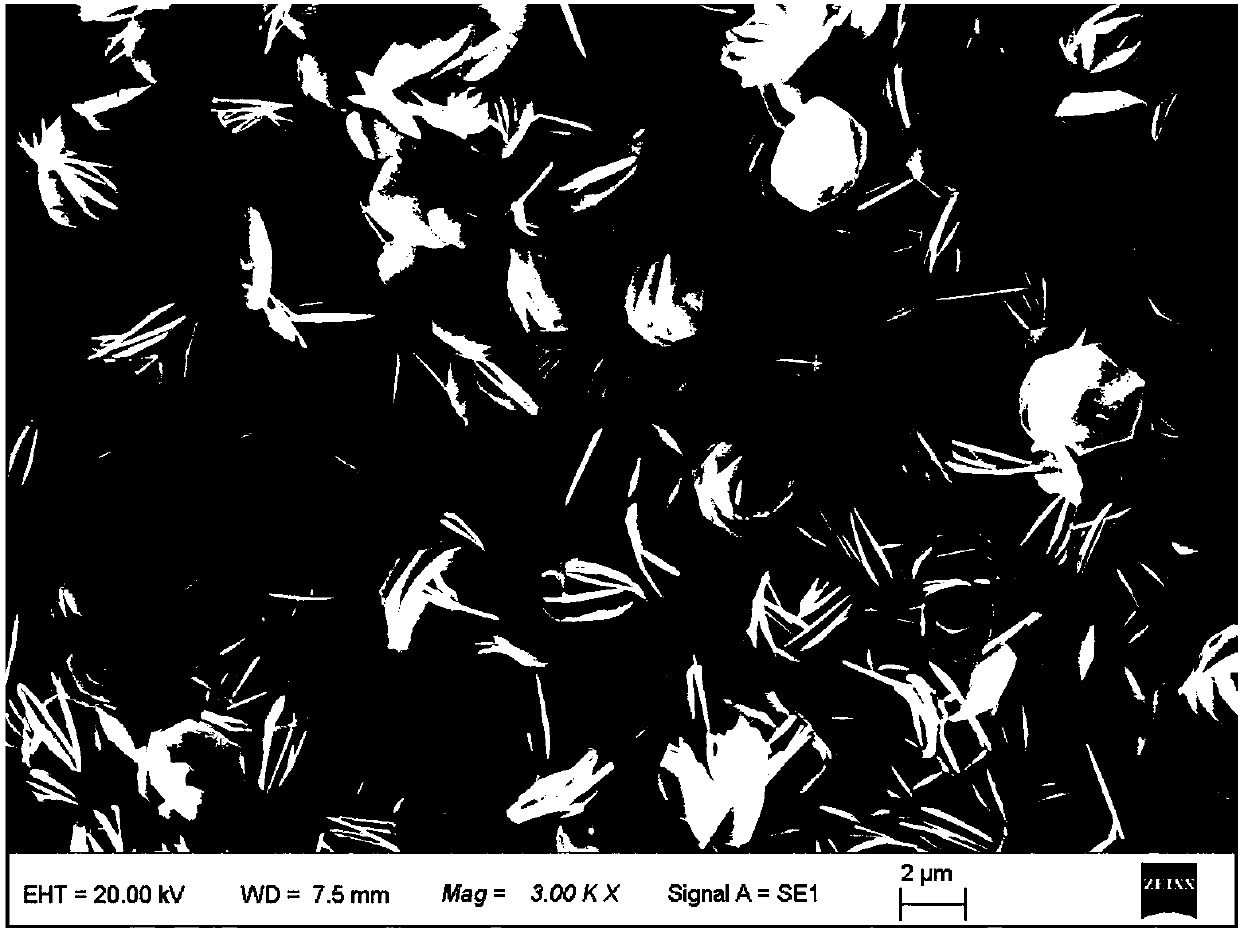

Image

Examples

preparation example Construction

[0016] The present invention proposes a kind of preparation method of layered double metal hydroxide composite nanofiltration membrane, comprises the following steps:

[0017] S1, immersing the basement membrane in an alkaline aqueous solution containing dopamine monomer for reaction, forming a layer of polydopamine functional modification layer on the basement membrane;

[0018] S2, putting the polydopamine-modified basement membrane into a reactor containing a metal salt precursor and a precipitating agent, and heating to form a layered double metal hydroxide functional surface layer on the basement membrane in situ to obtain a composite nanofiltration membrane.

[0019] Further, in a preferred embodiment of the present invention, the base membrane is selected from one of polysulfone porous membranes, polyethersulfone porous membranes, polyacrylonitrile porous membranes, polyvinylidene fluoride membranes, and polyamide composite membranes. Since the functional modification o...

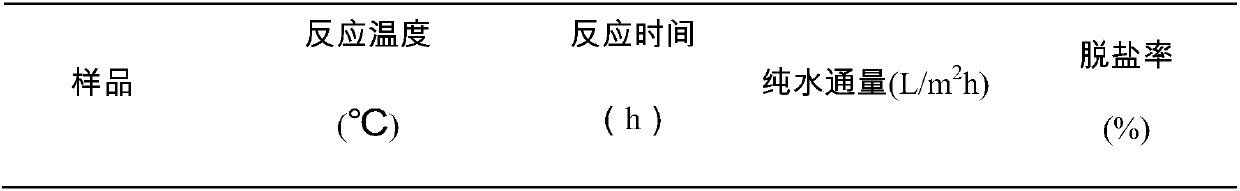

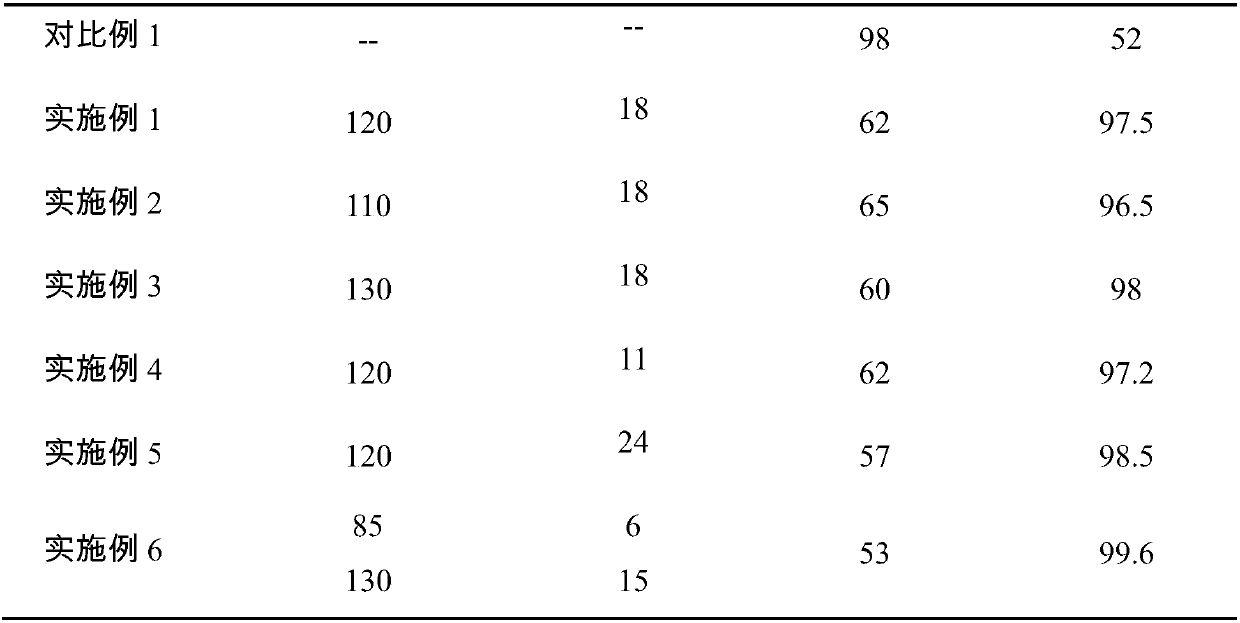

Embodiment 1

[0028] First, the polyamide-based membrane is directly immersed in an alkaline aqueous solution containing 2g / L dopamine monomer at pH=8.5 for 10 hours to form a layer of polydopamine functional modification layer on the base membrane; In the reactor of aluminum chloride, 135mmol / L magnesium chloride precursor and 15g / L urea precipitant, the hydrothermal reaction was carried out at 120°C for 18h, and finally a layered double metal hydroxide functional surface layer was formed in situ on the polydopamine-modified basement membrane , to obtain a composite nanofiltration membrane. After rinsing several times with deionized water, the prepared composite membrane was kept in water.

Embodiment 2

[0030] Example 2 is basically the same as Example 1, except that the temperature of the hydrothermal reaction is 110° C. and the time is 18 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com