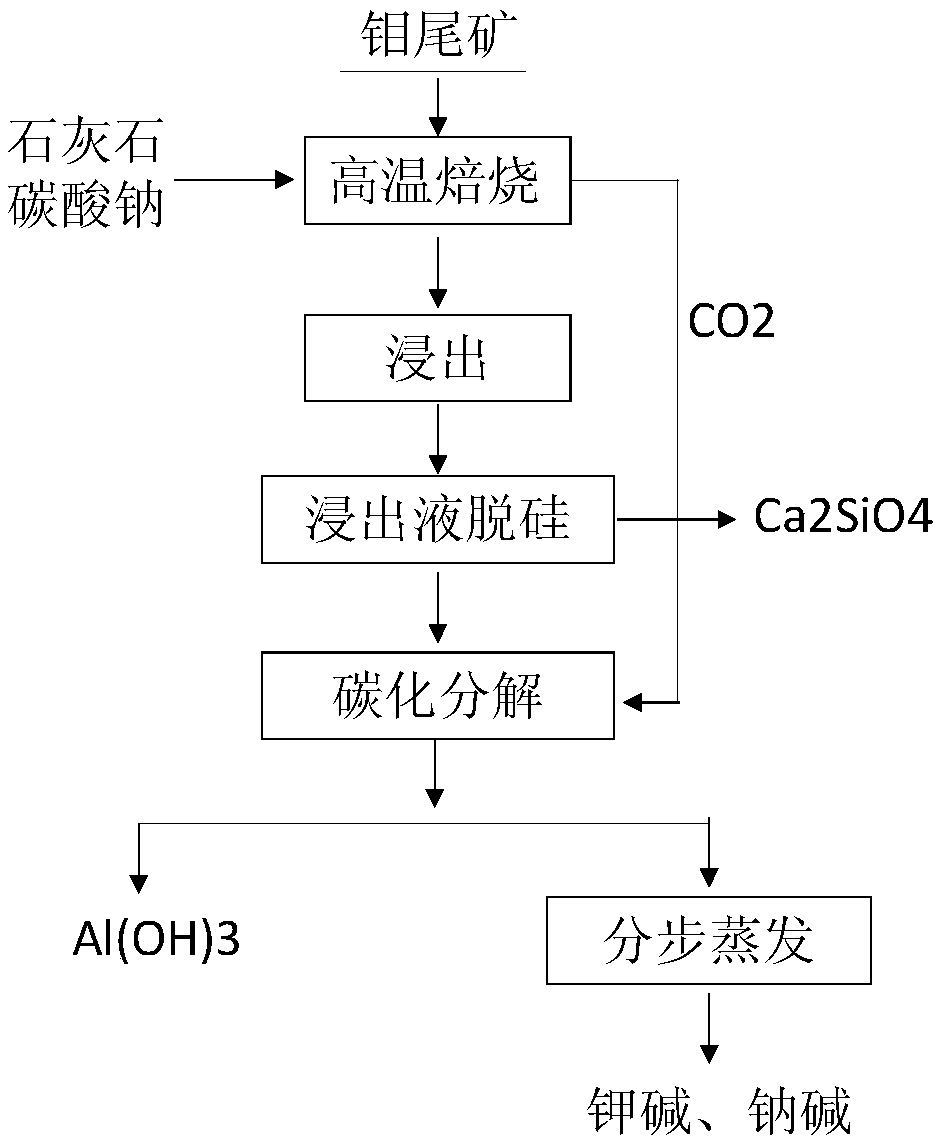

A method for comprehensive recovery of aluminum, potassium, sodium and silicon from molybdenum tailings

A technology of molybdenum tailings and aluminum recovery, which is applied in the direction of improving process efficiency, can solve the problems of lack of economical and effective utilization methods, environmental pollution, etc., and achieve the effects of realizing waste utilization, reducing production costs, and protecting the ecological environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The raw material comes from molybdenum tailings in a mining area in Henan, and the main content of each component is SiO 2 : 71.52%, Al 2 o 3 : 11.32%, K 2 O: 4.98%, Na 2 O: 2.56%, CaO: 1.75%, MgO: 0.48%, Fe 2 o 3 : 0.68%.

[0035] According to the mass ratio, molybdenum tailings: calcium carbonate: sodium carbonate = 100:130:1.8, with molybdenum tailings, limestone, sodium carbonate;

[0036] After the raw ore is crushed and ground, mixed with limestone and sodium carbonate at a mass ratio of 100:130:1.8, the temperature is raised to 850°C for high-temperature roasting for 2 hours; the sintered product is dissolved in an aqueous solution, and the dissolution temperature is 65°C. The ratio is 2:1, the leaching time is 1h, and the leaching residue is filtered to obtain calcium orthosilicate product (the purity of calcium orthosilicate product is 92wt% and the content of Na is less than 0.02wt%) (the recovery rate of Si is 89%) , can be used as cement raw material;...

Embodiment 2

[0038] The raw material is molybdenum tailings from a place in Anhui, and the main content of each component is SiO 2 : 70.89%, Al 2 o 3 : 10.54%, K 2 O: 4.79%, Na 2 O: 2.13%, CaO: 1.53%, Fe 2 o 3 : 0.89%.

[0039] According to the mass ratio, molybdenum tailings: calcium carbonate: sodium carbonate = 100:120:1.9, with molybdenum tailings, limestone, sodium carbonate;

[0040] After the raw ore is crushed and ground, the mass ratio of limestone and sodium carbonate ore is 100:120:1.9, and the reaction temperature is 900°C for high-temperature roasting for 2.5 hours; is 3:1, the leaching time is 1h, the calcium orthosilicate product is obtained by filtering the leaching slag (the purity of the calcium orthosilicate product is 93% and the content of Na is less than 0.015wt%), can be used as cement raw material (the recovery rate of Si is 93%); the eluate is fed into the carbon dioxide gas in the airtight container to carry out the carbonization reaction, the pressure of t...

Embodiment 3

[0042] The raw material is molybdenum tailings from a place in Xi'an, and the main content of each component is SiO 2 : 71.28%, Al 2 o 3 : 10.69%, K 2 O: 5.12%, Na 2 O: 1.25%, CaO: 3.14%, Fe 2 o 3 : 2.35%.

[0043]After the raw ore is crushed and ground, the mass ratio of limestone and sodium carbonate ore is 100:125:1.2, and the reaction temperature is 950°C for high-temperature roasting for 3 hours; the sintered product is dissolved in an aqueous solution, the dissolution temperature is 85°C, and the liquid-solid ratio is 2:1, the leaching time is 0.5h, the calcium orthosilicate product is obtained by filtering the leaching slag (the purity of the calcium orthosilicate product is 95% and the content of Na is less than 0.01wt%), which can be used as cement raw material; Carbon dioxide gas is introduced into the container for carbonization reaction. The pressure of carbon dioxide gas introduced during the carbonization decomposition process is 2MPa, the reaction time is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com