Polyimide preparation method and application thereof

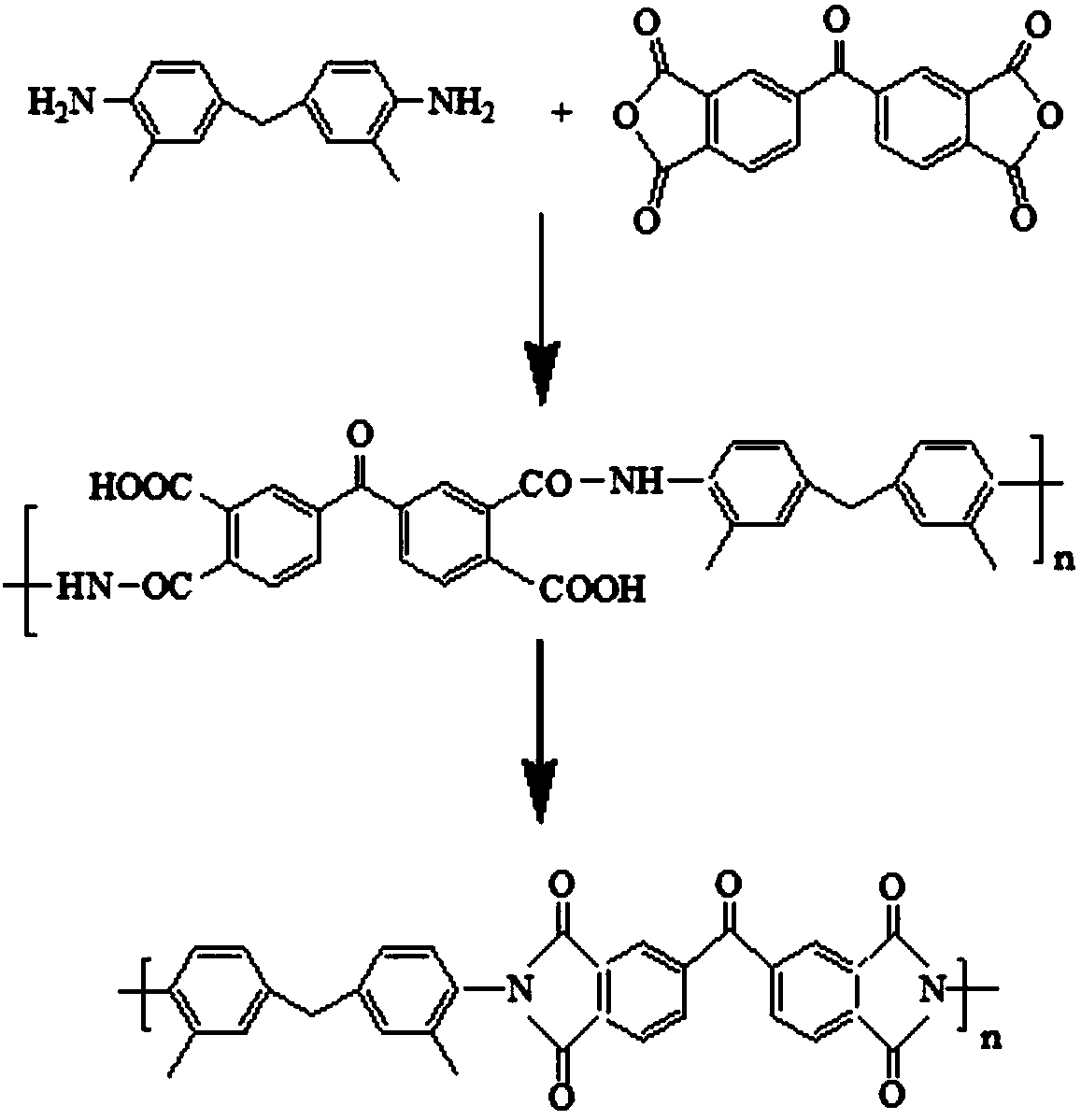

A technology of polyimide and polyamic acid, applied in the field of resin, can solve the problems of poor fluidity, insoluble and insoluble, application limitation, etc., and achieve the effect of improving solubility and solubility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Under the protection of an inert gas and at a temperature of -10°C to 10°C, dissolve the aromatic diamine monomer 3,3'-dimethyl-4,4'-diaminodiphenylmethane in a certain amount of N, In N-dimethylformamide, the solid content of the monomer is controlled to be 10%. After the diamine is completely dissolved, a certain amount of 3,3′,4,4′-benzophenone tetraacid dianhydride, diamine and The molar ratio of 3,3′,4,4′-benzophenonetetraacid dianhydride is 1:1.01, the reaction temperature is controlled at 5°C, and the reaction is carried out for 10-13 hours, and then a certain amount of chemical imidization reagent acetic anhydride / pyridine is added After continuing to stir and react for a period of time, a polyimide solution was obtained, and a polyimide solid was obtained after ethanol water precipitation, washing, and vacuum drying.

[0024] After testing, the weight average molecular weight Mw of the polyimide obtained in this embodiment is 3*10 6 , the average chain spacing...

Embodiment 2

[0026] Under the protection of an inert gas and at a temperature of 5°C to 10°C, dissolve the aromatic diamine monomer 3,3′-dimethyl-4,4′-diaminodiphenylmethane in a certain amount of N,N -In dimethylformamide, the solid content of the monomer is controlled to be 6%. After the diamine is completely dissolved, a certain amount of 3,3',4,4'-diphenylmethyl ether tetraacid dianhydride, diamine and The molar ratio of dianhydride is 1:0.99, and the reaction temperature is controlled at 5°C for 10-13 hours. Add a certain amount of chemical imidization reagent acetic anhydride / picoline, continue to stir and react for a period of time to obtain a polyimide solution, and obtain a polyimide solid after precipitation with ethanol water, washing, and vacuum drying.

[0027] After testing, the weight-average molecular weight Mw of the polyimide obtained in this embodiment is 3.5*10 6 , the average chain spacing is 0.56nm; the temperature at 10% thermal decomposition is 510°C; the glass tra...

Embodiment 3

[0029] Preparation of composite nanofiltration membrane:

[0030] 1) Take 10 g of the polyimide solid prepared in Example 1 above, dissolve it in 85 ml of polar protic solvent at room temperature, dissolve evenly, filter it with a 300-mesh steel mesh, and vacuum debubble it for later use. In a dust-free environment at 25°C and a humidity of 50-70%, the above-mentioned casting solution is coated on PET non-woven fabrics, with a wet film thickness of 250um, and phase-inverted in water or ethanol to form a film for use to obtain polyimide basement membrane.

[0031] 2) Immerse the polyimide base film prepared above in alcohol for a period of time to remove the residual moisture in the film by solvent exchange, and then immerse in a certain concentration of diamine / alcohol solvent for crosslinking for a period of time, the crosslinked The membrane is stored in an alcohol solvent to prevent the membrane pores from collapsing and is used to prepare PA / PI composite nanofiltration me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com