Single particle surface plasmon electrooptical modulator and manufacturing method thereof

A surface plasmon, electro-optic modulator technology, applied in instruments, optics, nonlinear optics, etc., can solve problems such as unfavorable device miniaturization and speed improvement, and achieve small device size, high response rate, and response speed. quick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0053] The preparation method of the molybdenum disulfide-based single-particle surface plasmon electro-optic modulator is further given below, and the preparation of the electro-optic modulator includes the following steps:

[0054] Step 1, the SiO 2 / Si substrate is ultrasonically cleaned with an organic solvent, and ultrasonically cleaned in the order of acetone (10-15min)→ethanol (10-20min)→deionized water (20-30min), and finally the remaining on the substrate is cleaned with a nitrogen gun. Blow dry with deionized water to get clean SiO 2 / Si substrate.

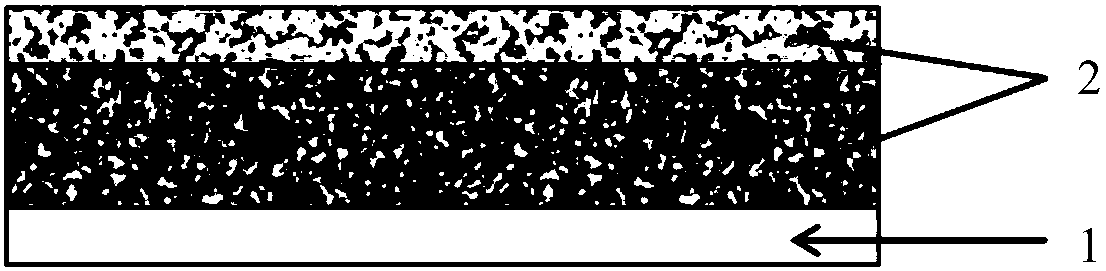

[0055] Step two, such as figure 2 As shown, the SiO obtained in the previous step 2 The Si surface of the / Si substrate 2 is coated with Ti and Au as the bottom electrode 1 in turn by using electron beam evaporation coating method to obtain SiO with the bottom electrode. 2 / Si substrate. In order to obtain better film thickness and quality, the vacuum degree of the electron beam evaporation coating instrument shoul...

Embodiment 1

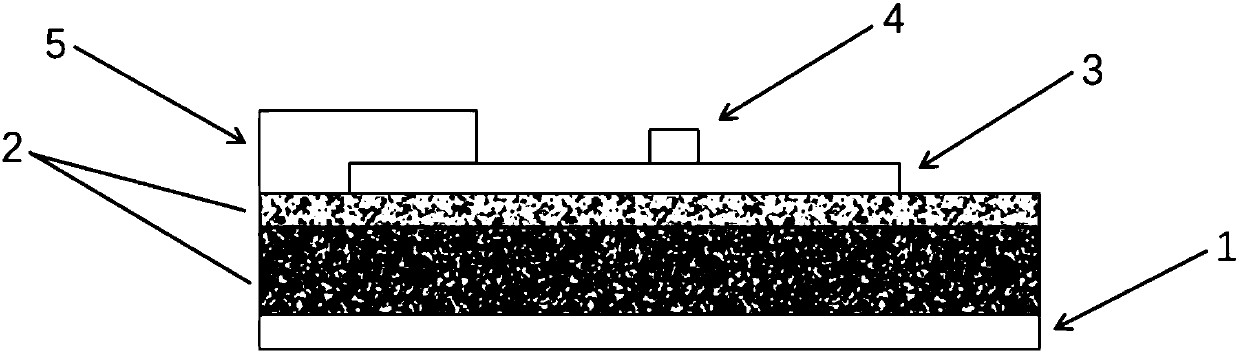

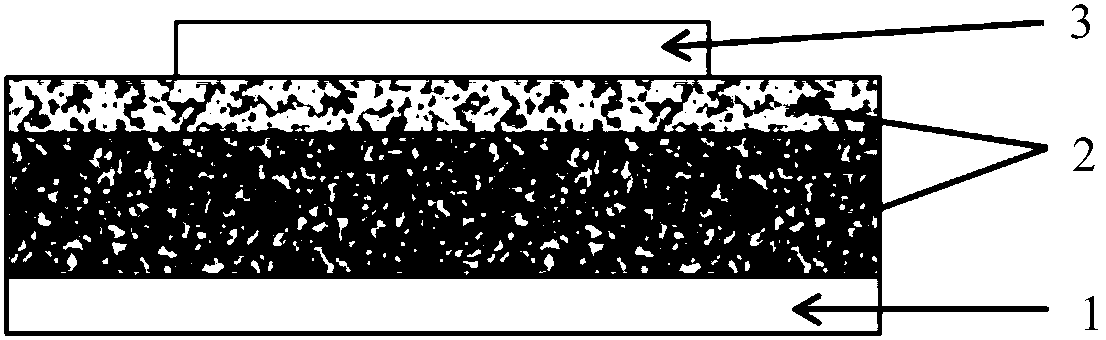

[0062] Optical diagram of a single-particle surface plasmon electro-optic modulator based on molybdenum disulfide Figure 6 As shown, from bottom to top including bottom electrode 1, SiO 2 / Si substrate 2, single-layer molybdenum disulfide 3, metal nanodisc 4 and top electrode 5. Among them, the bottom electrode 1 is in SiO 2 / Si substrate 2, the monolayer molybdenum disulfide 3 after wet transfer is in SiO 2 / Si substrate 2, the metal nano-disc 4 produced by electron beam exposure is on the single-layer molybdenum disulfide 3, the material of the metal nano-disc 4 is gold, the height is 30nm, and the radius is 60nm (under this size, The coupling efficiency calculated by FDTD solutions software is the best). The top electrode 5 is above the single layer of molybdenum disulfide 3 and away from the area of the metal nanodisc 4 . Both the top electrode 5 and the bottom electrode 1 are obtained by evaporating 5nmTi / 80nm Au by electron beam evaporation coating. The two electro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com