Prussia white composite material and preparation method and application thereof

A composite material, Prussian white technology, applied in the field of new energy storage batteries, can solve the problems of poor crystallinity of ferrocyanide, reduce battery energy density, low capacity of sodium ion batteries, etc. Optimizing the effect of preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

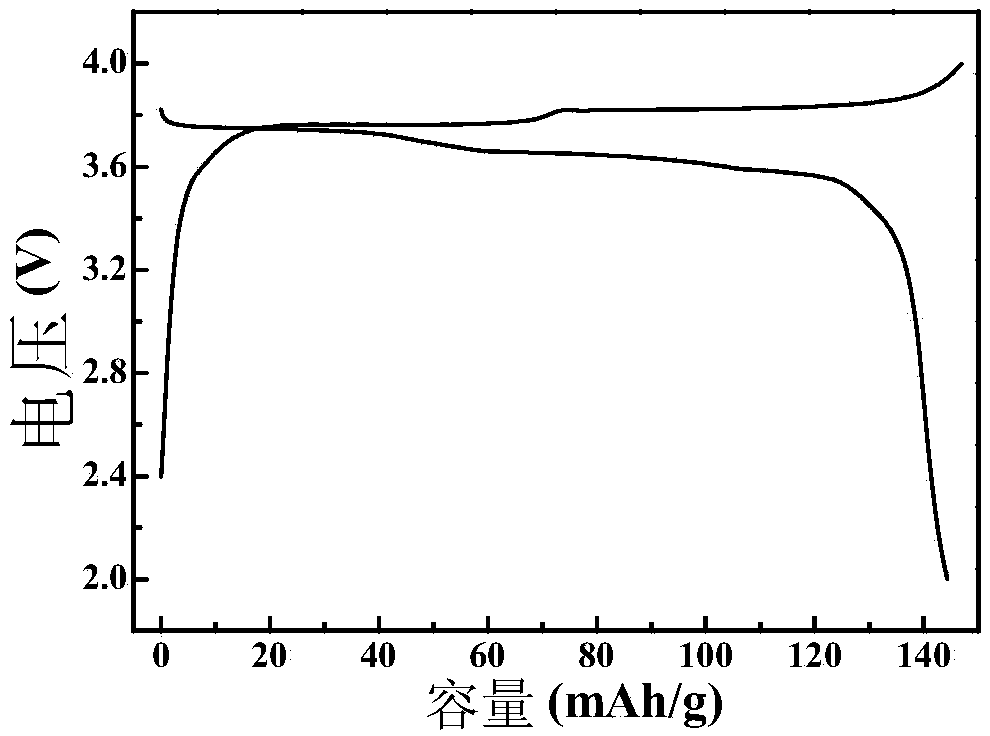

Embodiment 1

[0028] Sodium ferrocyanide is dissolved in deionized water, and stirred evenly to obtain solution A whose concentration is 0.1mol / L in terms of ferrocyanide ion; manganous chloride is dissolved in deionized water to obtain 2+ A solution with a metered concentration of 0.2mol / L, wherein the molar weight of manganese chloride is 1.5 times that of sodium ferrocyanide, plus fluorinated carbon nanotubes, the fluorine content of fluorinated carbon nanotubes is 15%, and the amount added It is 6% of the theoretical weight of Prussian white, and solution B is obtained through sufficient ultrasonic dispersion; then, under continuous stirring, solution B is added dropwise to solution A, and subjected to hydrothermal reaction at 80°C for 10 hours, and then cooled, washed, and vacuum The drying temperature is not lower than 120°C, and the drying time is not less than 12 hours to obtain the Prussian white composite material.

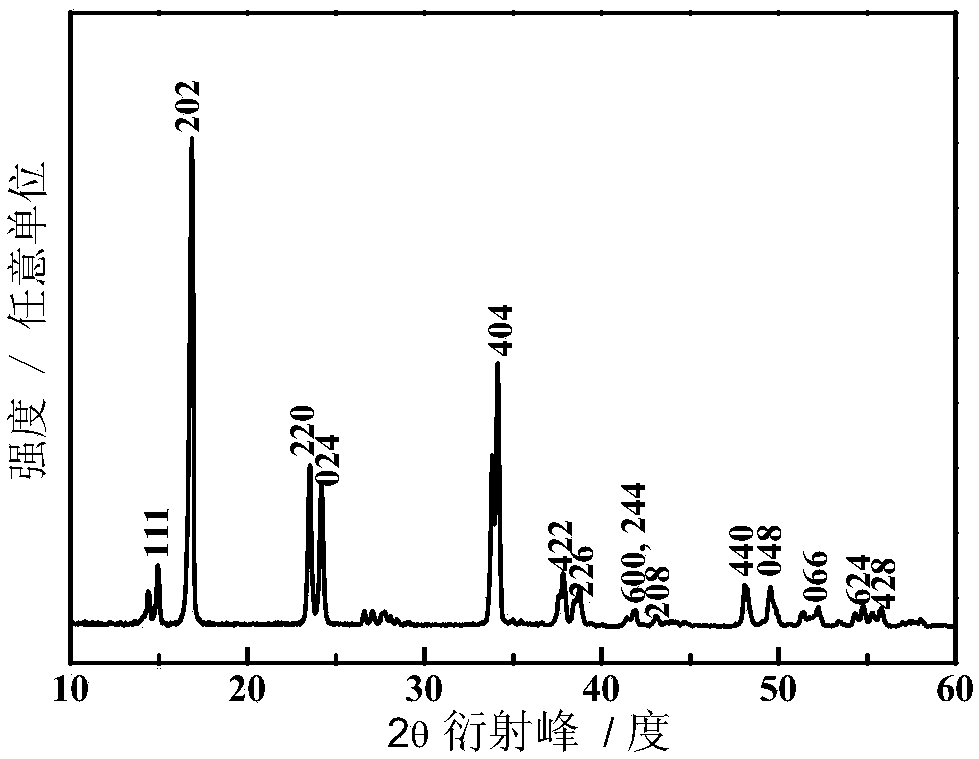

[0029] figure 1 The X-ray diffraction spectrum of the Prussian ...

Embodiment 2

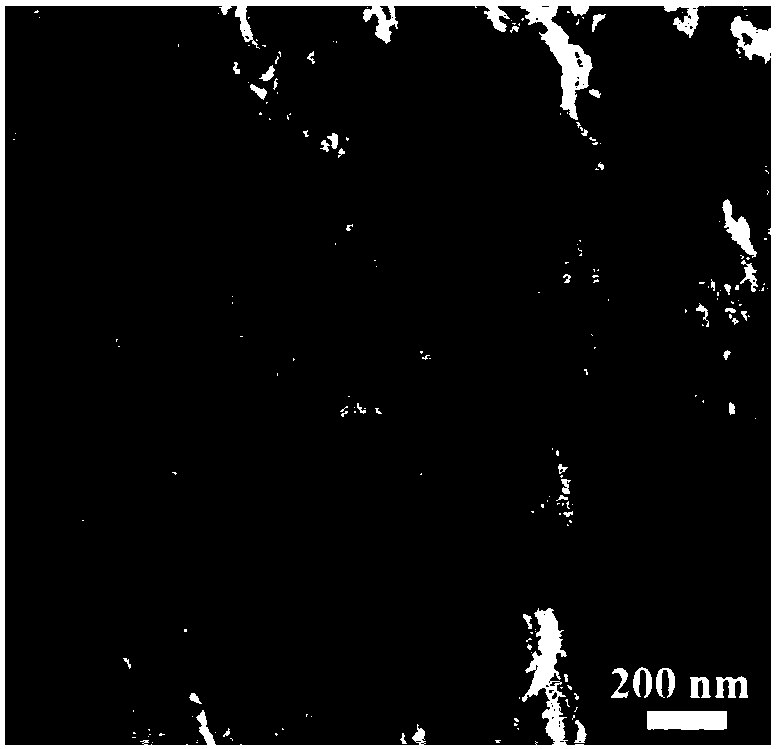

[0041] Sodium ferrocyanide is dissolved in deionized water, and stirred evenly to obtain solution A whose concentration is 0.15mol / L in terms of ferrocyanide ion; manganous sulfate is dissolved in deionized water to obtain 2+ A solution with a metered concentration of 0.3 mol / L, wherein the molar weight of manganous sulfate is twice that of sodium ferrocyanide, and then adding fluorinated carbon nanotubes in an amount of 7% of the theoretical weight of Prussian white, which is obtained by fully stirring Solution B; then, under constant stirring, add solution B dropwise to solution A, and undergo hydrothermal reaction at 90°C for 8 hours, then cool, wash, and vacuum dry at a temperature not lower than 120°C, and the drying time is not less than 12 hours Then get the Prussian white composite material. XRD shows that the product is sodium ferromanganese cyanide in the rhombohedral phase. Scanning electron microscopy shows that the particle size of Prussian white is 300-500nm, and...

Embodiment 3

[0044] Dissolve sodium ferrocyanide in deionized water, stir evenly to obtain a solution A with a concentration of 0.2 mol / L in terms of ferrocyanide ions; dissolve manganese nitrate in deionized water to obtain 2+ A solution with a metered concentration of 0.4mol / L, wherein the molar weight of manganese nitrate is 2.5 times that of sodium ferrocyanide, then add fluorinated carbon nanotubes, the fluorine content of fluorinated carbon nanotubes is 10%, and the addition amount is 5% of the theoretical weight of Prussian white, after fully stirring to obtain solution B; then under continuous stirring, solution B was added dropwise to solution A, and subjected to hydrothermal reaction at 60°C for 6h, then cooled, washed, and vacuumed at 120°C A Prussian white composite was obtained after drying for 12 hours. XRD shows that the product is sodium ferromanganese cyanide in the rhombohedral phase. Scanning electron microscopy shows that the particle size of Prussian white is 300-500nm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com