A kind of sulfonic acid type cation exchange resin microsphere and preparation method thereof

A technology of cation exchange and resin microspheres, which is applied in the direction of cation exchange, ion exchange, chemical instruments and methods, etc., can solve the problems of wasting resources, particle size does not meet the requirements, increase energy consumption, etc., and achieve large ion exchange capacity and post-treatment Simple, Gentle Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

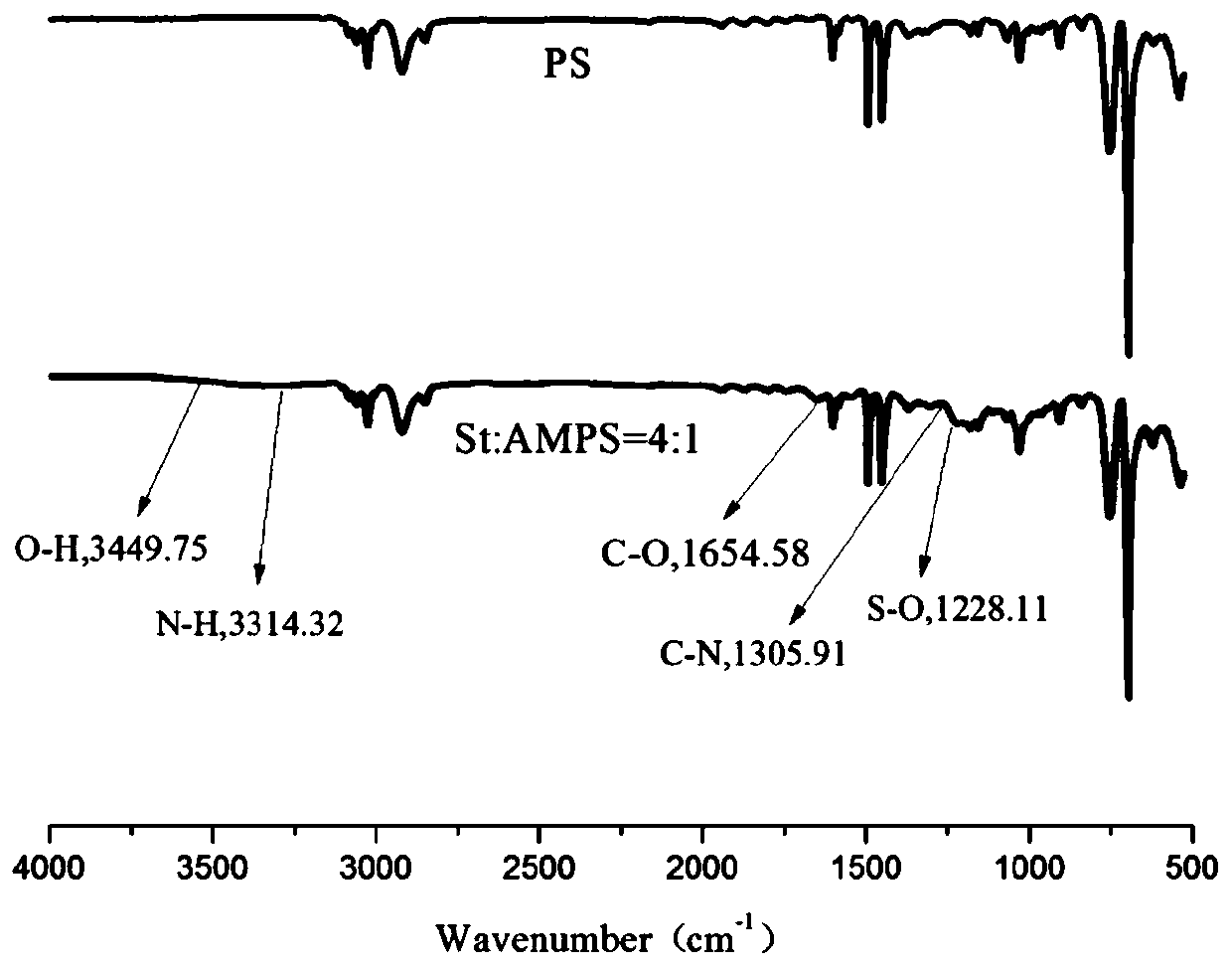

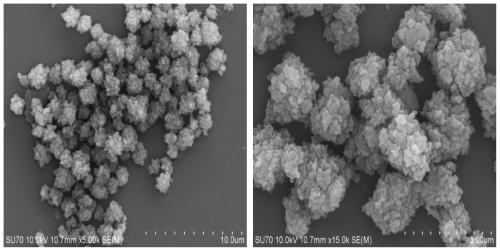

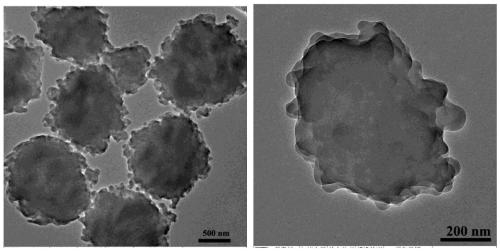

[0036] 1) Under nitrogen protection, add 80mL deionized water, 3.62g AMPS, 0.067g MBA to a 250ml three-necked flask equipped with a stirring magnet and a condensing reflux device, stir well, then continue to add 4mL St, 25μL DVB, heat Raise the temperature to 75°C, keep the temperature for 10min, add 0.1g potassium persulfate (KPS) aqueous solution (dissolve 0.1g potassium persulfate in 20mL deionized water), react for 24h, use absolute ethanol and deionized water to deionize the product several times Centrifugal washing, vacuum drying to obtain milky white solid powder, which is polystyrene microspheres;

[0037] 2) Swell the milky white solid powder (0.2g) with 10mL of dichloromethane for 30min, and finally add a mixed solution of chlorosulfonic acid and dichloromethane (5mL of chlorosulfonic acid, 15mL of dichloromethane) dropwise under constant pressure, and carry out at room temperature After sulfonation reaction for 8 hours, and then centrifuged and washed with deionized...

Embodiment 2

[0039] 1) Under nitrogen protection, add 80mL of deionized water, 1.81g of AMPS, 0.034g of MBA to a 250ml three-necked flask equipped with a stirring magnet and a condensing reflux device, stir well, then continue to add 4mL of St, 25μL of DVB, and heat Raise the temperature to 75°C, keep the temperature for 10min, add 0.1g potassium persulfate (KPS) aqueous solution (dissolve 0.1g potassium persulfate in 20mL deionized water), react for 24h, use absolute ethanol and deionized water to deionize the product several times Centrifugal washing, vacuum drying to obtain milky white solid powder, which is polystyrene microspheres;

[0040] 2) Swell the milky white solid powder (0.2g) with 10mL of dichloromethane for 30min, and finally add a mixed solution of chlorosulfonic acid and dichloromethane (5mL of chlorosulfonic acid, 15mL of dichloromethane) dropwise under constant pressure, and carry out at room temperature After sulfonation reaction for 12 hours, and then centrifuged and w...

Embodiment 3

[0043]1) Under nitrogen protection, add 80mL deionized water, 0.904g AMPS, 0.017g MBA to a 150ml three-necked flask equipped with a stirring magnet and a condensing reflux device, stir well, then continue to add 4mL St, 25μL DVB, heat Raise the temperature to 75°C, keep the temperature for 10min, add 0.1g potassium persulfate (KPS) aqueous solution (dissolve 0.1g potassium persulfate in 20mL deionized water), react for 24h, use absolute ethanol and deionized water to test the product several times Centrifugal washing, vacuum drying to obtain milky white solid powder, which is polystyrene microspheres;

[0044] 2) Swell the milky white solid powder (0.2g) with 10mL of dichloromethane for 30min, and finally add a mixed solution of chlorosulfonic acid and dichloromethane (5mL of chlorosulfonic acid, 15mL of dichloromethane) dropwise under constant pressure, and carry out at room temperature After sulfonation reaction for 16 hours, and then centrifuged and washed with deionized wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com