Photovoltaic module bus bar insulated rubber tape, bus bar containing insulated rubber tape and photovoltaic module

An insulating tape, photovoltaic module technology, applied in photovoltaic modules, photovoltaic power generation, adhesives, etc., can solve the problems of poor heat resistance, poor adhesion, low efficiency, etc., and achieve excellent adhesion and adhesion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] The preferred embodiments of the present invention will be described in detail below in conjunction with specific examples.

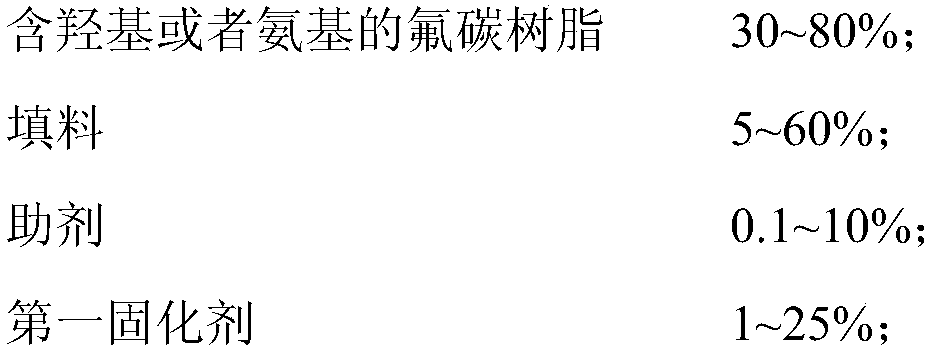

[0069] 1, Preparation of insulating tape

[0070] The hydroxyfluorocarbon resin is dissolved in butyl acetate (or commonly used ethyl acetate, acetone, toluene, xylene, N,N-dimethylformamide, etc.) solvent at 50% by mass, and hydrogenated epoxy Resin, carbon black filler, dispersant BYK9076, after dispersion and sanding treatment. Then add isocyanate curing agent, dibutyltin dilaurate curing accelerator, and stir evenly, and evenly coat a 5 μm thick coating on the polyimide film (PI). Heat to evaporate to dryness, then roll up for later use.

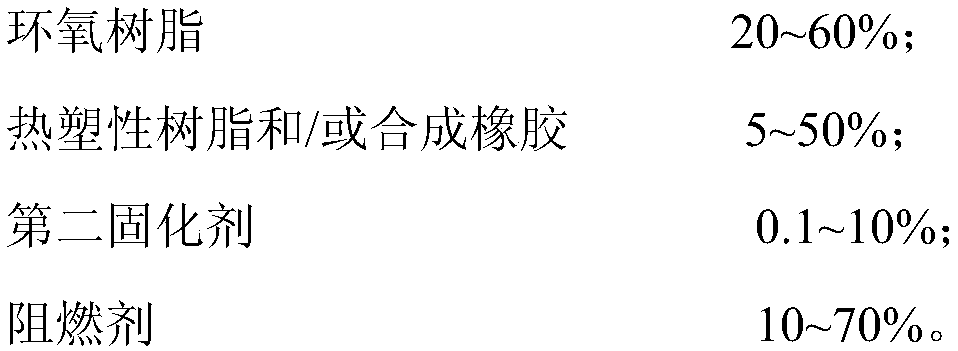

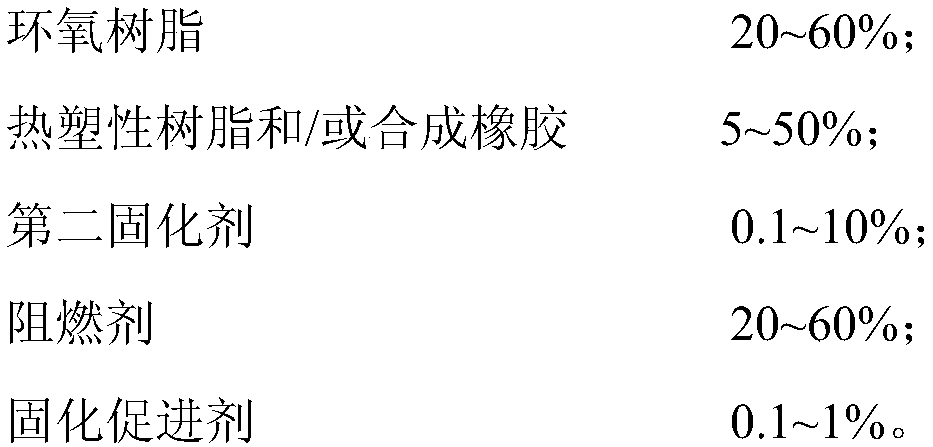

[0071] Epoxy resin, thermoplastic resin and / or synthetic rubber are dissolved in butanone (or commonly used acetone, toluene) by mass percentage as 20% in butanone (or commonly used acetone, toluene, Xylene, N,N-dimethylformamide, etc.) solvent, and then add flame retardant to the resin solution, after...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com