A method for extracting rare earth from rare earth phosphor waste and fluorine-containing rare earth electrolysis waste

A rare earth phosphor and rare earth technology, applied in the direction of improving process efficiency, can solve the problems of single processing object, low leaching rate of rare earth elements, high comprehensive energy consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] Provide phosphor waste 100Kg, which contains 27.2Kg of rare earth REO (which mainly contains 7.35% of cerium, 5.94% of europium, 3.70% of terbium, and 81.39% of yttrium), and 25.8Kg of aluminum oxide. Rare earth molten salt waste 100Kg, which contains 42.3Kg of rare earth REO (including 16.06% of praseodymium and 82.14% of neodymium), and 17.6Kg of fluorine.

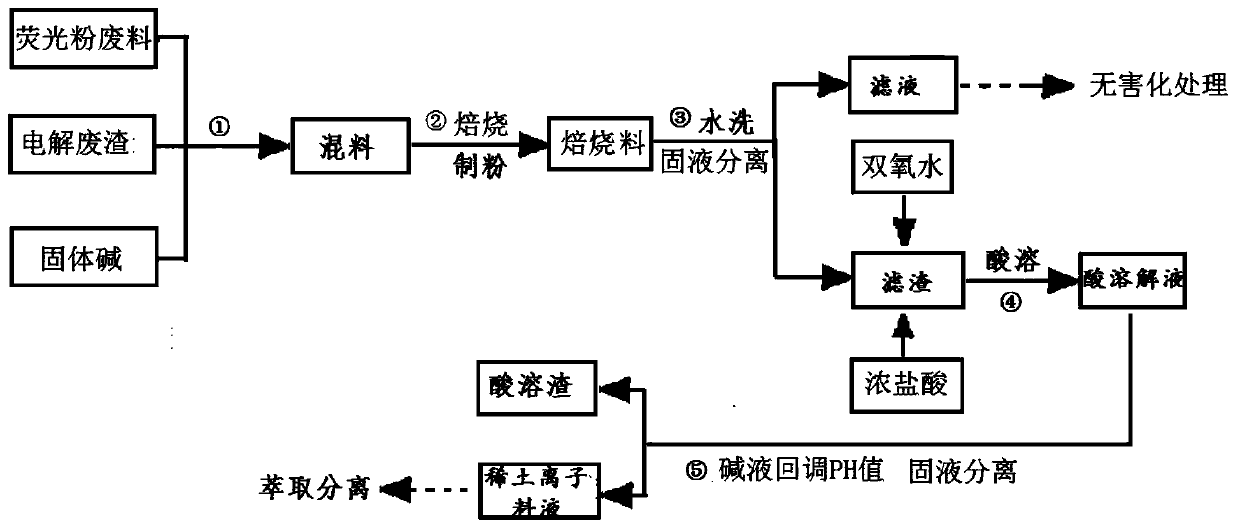

[0055] According to attached figure 1 The flow chart shown is to extract rare earth from rare earth phosphor waste and fluorine-containing rare earth electrolytic waste. The rare earth fluorescent powder waste, fluorine-containing rare earth electrolytic waste residue and sodium hydroxide are uniformly mixed in a mass ratio of 1:1:0.6. Calcined at 500°C for 2 hours, cooled to obtain block-shaped calcined material and crushed to 200 mesh with a Raymond machine.

[0056] Put the burning material in the washing bucket, add about 2 tons of water to the washing bucket and wash for 3 times until the pH value is about ...

Embodiment 2

[0060] Provide 100Kg of phosphor waste, which contains 27.2Kg of rare earth REO (which mainly contains 7.35% of cerium, 5.94% of europium, 3.70% of terbium, and 81.39% of yttrium), and 25.8Kg of aluminum. Rare earth molten salt waste 100Kg, which contains 42.3Kg of rare earth REO (including 16.06% of praseodymium and 82.14% of neodymium), and 17.6Kg of fluorine.

[0061] The rare earth fluorescent powder waste, fluorine-containing rare earth electrolytic waste and sodium hydroxide are uniformly mixed in a mass ratio of 1:1:1. Calcined at 800° C. for 4 hours, cooled to obtain block-shaped calcined material and crushed to 200 mesh with a Raymond machine.

[0062] Put the burning material in the washing bucket, add about 2 tons of water to the washing bucket and wash for 3 times until the pH value is about 7, press and separate to obtain about 179Kg of filter residue. Wash the slag in an acid-soluble barrel with about 0.27 cubic meters of concentrated hydrochloric acid with a co...

Embodiment 3

[0066] Provide 100Kg of phosphor waste, which contains 22.4Kg of rare earth REO (which mainly contains 8.26% of cerium, 7.34% of europium, 4.00% of terbium, and 79.30% of yttrium), and 25.8Kg of aluminum. 100Kg of rare earth molten salt waste residue, including 47.5Kg of rare earth REO (including 16.06% of praseodymium and 82.14% of neodymium), and 21.23Kg of fluorine.

[0067] The rare earth fluorescent powder waste, fluorine-containing rare earth electrolytic waste and sodium hydroxide are uniformly mixed in a mass ratio of 1:1:0.8. Calcined at 700°C for 3 hours, cooled to obtain a block-shaped calcined material and crushed to 200 mesh with a Raymond machine.

[0068]Put the burning material in the washing bucket, add about 2 tons of water to the washing bucket and wash it three times until the pH value is about 7, press and separate to obtain about 193Kg of filter residue. Wash the slag in an acid-soluble tank with about 0.28 cubic meters of concentrated hydrochloric acid ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com