Unmanned plant protection machine spraying preparation and preparation method thereof

A plant protection machine and preparation technology, applied in botany equipment and methods, plant growth regulators, applications, etc., can solve the problems of poor control effect, achieve low price, obvious synergistic effect, and improve control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

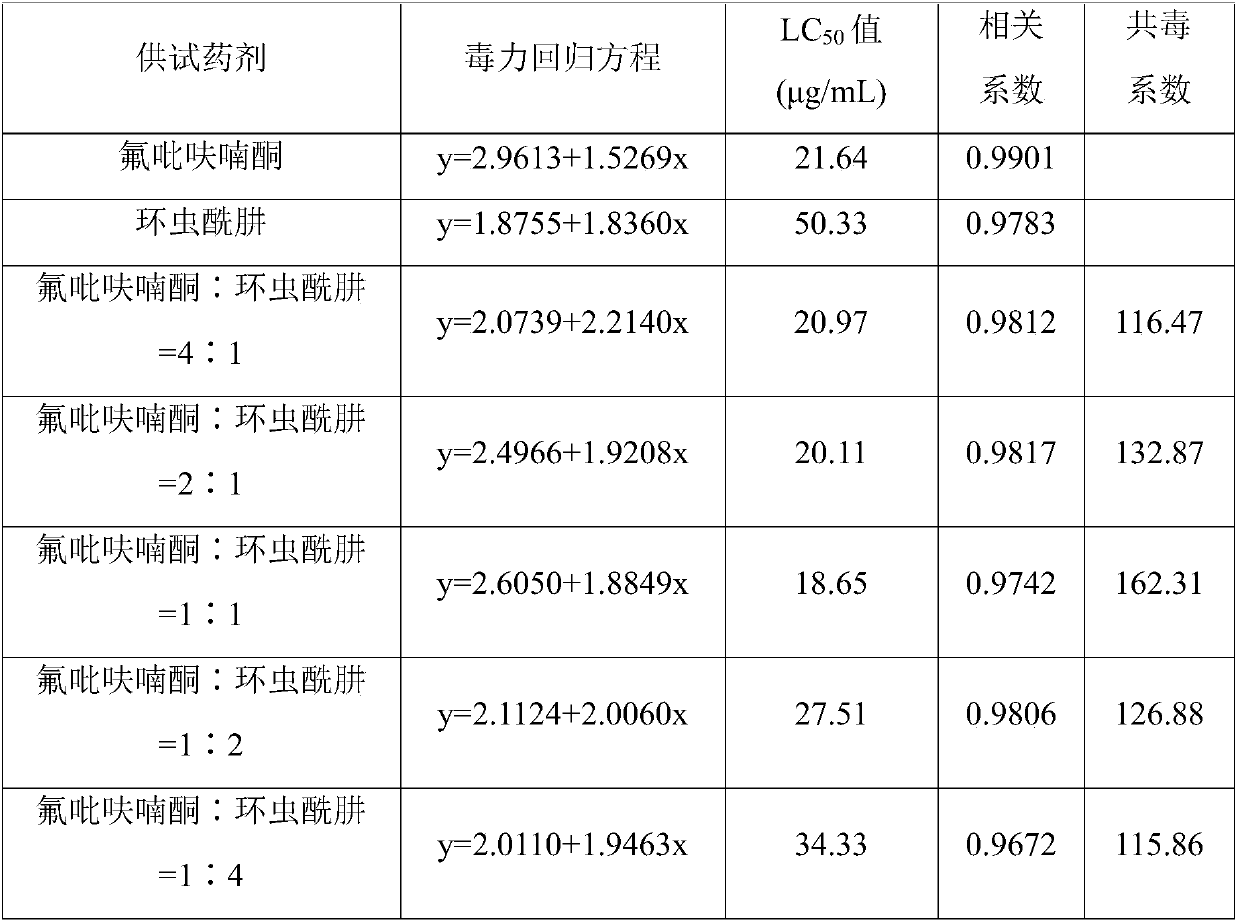

Method used

Image

Examples

Embodiment 1

[0017] Example 1: Composition and preparation method of 40.1% flupyrfurone·cyclafenozide aqueous emulsion:

[0018] The mass percentage (%) of each active ingredient of the main agent of this example is: flurpirfurone 40.0, fenfenozide 0.1;

[0019] The mass percentage (%) of each component of the auxiliary agent is: solvent: ethylene glycol 10.0, dimethylformamide 10.0; emulsifier: 2,4,6-tris(1-phenylethyl)phenol poly(20) ethylene glycol Alcohol Phosphate Monoester 6.0, Polyoxyethylene Phenylphenol Ether 8.0; Dispersant: Sodium Lignosulfonate 5.0; Antifreeze Agent: Glycerol 2.0, Polyethylene Glycol 3.0; Stabilizer: Pyrogallic Acid 4.0, Sudan Black 1.0; Water 10.9.

[0020] After mixing the raw materials with the above mass ratio, the aqueous emulsion is processed into an aqueous emulsion.

Embodiment 2

[0021] Example 2: Composition and preparation method of 40.0% flupyrfurone·cyclafenozide aqueous emulsion:

[0022] The mass percent (%) of each active ingredient in the main agent of this example is: flurpirfurone 20.0, fenfenozide 20.0;

[0023] The mass percentages (%) of each component of the adjuvant are: solvent: ethylene glycol 8.0, polyethylene glycol 6.0; emulsifier: ethoxylated alkyl ether 5.0, ethylene oxide-fatty acid primary amine condensate 5.0; dispersant: Sodium lignosulfonate 2.0; antifreeze agent: hexanediol 3.0, glycerol 1.0; stabilizer: butyl glycidyl ether 3.0, polyethylene glycol diglycidyl ether 2.0; water 25.0.

[0024] After mixing the raw materials with the above mass ratio, the aqueous emulsion is processed into an aqueous emulsion.

Embodiment 3

[0025] Example 3: Composition and preparation method of 20.0% flupyrfurone·cyclafenozide aqueous emulsion:

[0026] The mass percent (%) of each active ingredient in the main agent of this example is: flurpirfurone 10.0, fenfenozide 10.0;

[0027] The mass percentages (%) of each component of the adjuvant are: solvent: polyethylene glycol 5.0, N-long chain alkyl pyrrolidone 5.0; emulsifier: alkyl polyethylene glycol ether 6.0, 2,4,6-tri(1 -Phenylethyl)phenol poly(20)ethylene glycol phosphate monoester 5.0; dispersant: sodium lignosulfonate 1.0, sodium methylene bis-naphthalene sulfonate 1.5; antifreeze agent: hexanediol 1.0, glycerin 1.0; stabilizer: pyrogallic acid 1.0, p-nitrobenzoic acid 1.0; water 52.5.

[0028] After mixing the raw materials with the above mass ratio, the aqueous emulsion is processed into an aqueous emulsion.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com