A multi-layer anti-infection high-strength artificial dura mater and its preparation method

An artificial dura mater, high-strength technology, applied in the direction of prosthesis, filament/wire molding, fiber treatment, etc., can solve the problems of artificial dura mater anti-infection performance, limited anti-infection activity, insufficient bonding strength, etc. Achieve reliable anti-infection performance, protect brain tissue, and improve binding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

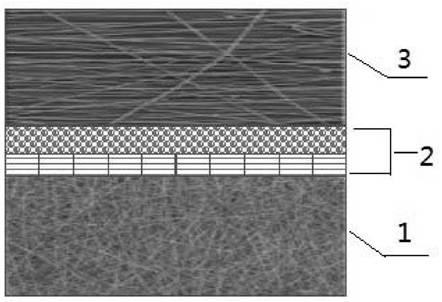

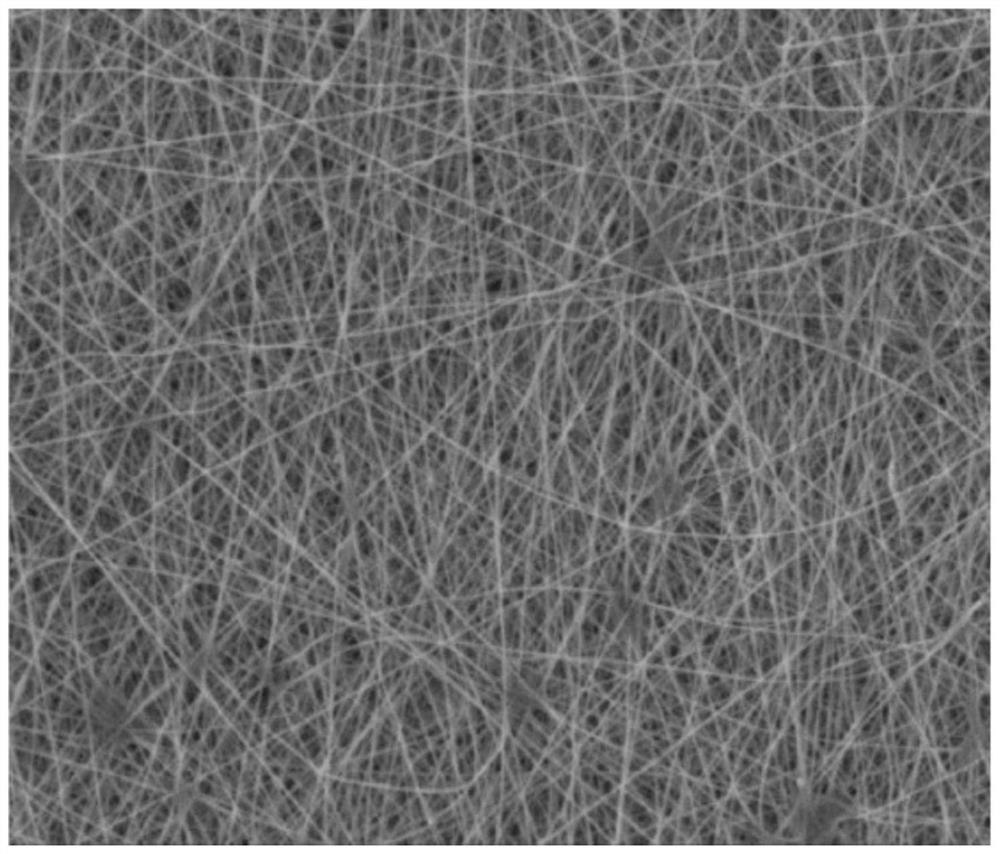

[0051] (1) Preparation of the inner layer: the inner layer material is polycaprolactone (Shenzhen Boli Biomaterials Co., Ltd.), dissolved in hexafluoroisopropanol (Suzhou Haofan Biological Co., Ltd.), and the concentration of the spinning solution is 5% (wt), stirred for 1 hour, electrospinning parameters were flow rate 1.0ml / h, voltage 12kV, receiving distance 15cm, electrospinning 2h.

[0052] (2) Preparation of the middle layer.

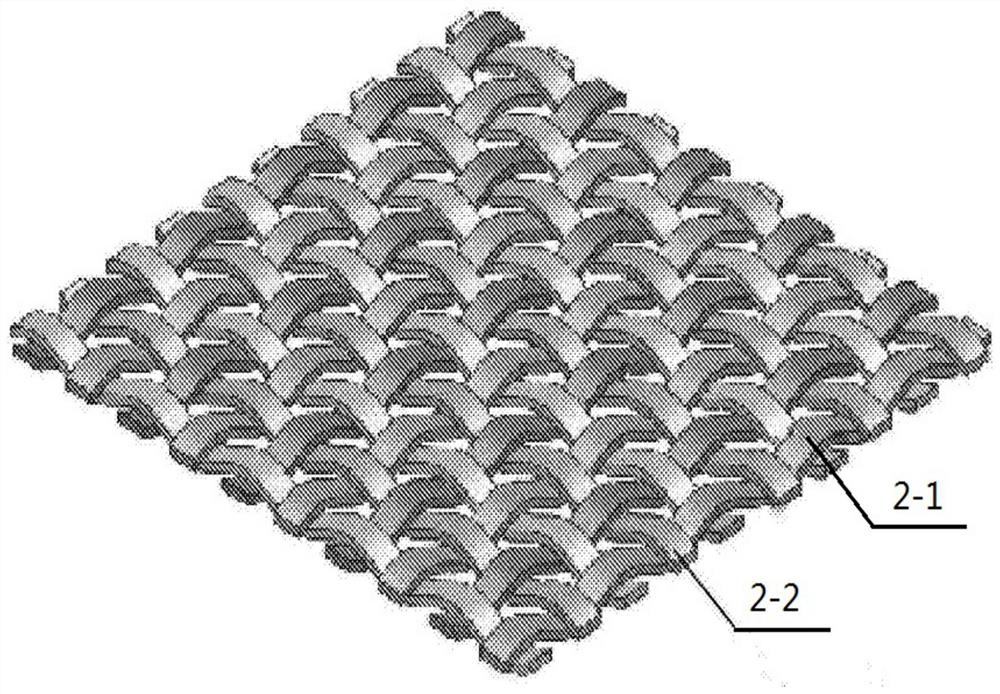

[0053] Films prepared by electrospinning carboxymethyl chitosan (Nantong Lvshen Bioengineering Co., Ltd.) with a film thickness of 40 μm. The film was made into thin strips with a width of 3 mm and a length of 1000 mm.

[0054] Films prepared by electrospinning polycaprolactone (Shenzhen Boli Biomaterials Co., Ltd.), with a film thickness of 40 μm. The film was made into thin strips with a width of 3 mm and a length of 1000 mm.

[0055] Two kinds of thin strips of 3mm x 1000mm face down, the hydrophilic thin strips are arranged horizontally, an...

Embodiment 2

[0062] (1) Preparation of the inner layer: the inner layer material is polycaprolactone (Shenzhen Boli Biomaterials Co., Ltd.), which is dissolved in hexafluoroisopropanol (Suzhou Haofan Biological Co., Ltd.), and the concentration of the spinning solution is 7%wt, stirred for 4 hours, electrospinning parameters were flow rate 0.9 ml / h, voltage 13kV, receiving distance 20cm, electrospinning 4h.

[0063] (2) Preparation of the middle layer.

[0064] Films prepared by electrospinning carboxymethyl chitosan (Nantong Lvshen Bioengineering Co., Ltd.) with a film thickness of 40 μm. The film was made into thin strips with a width of 3 mm and a length of 1000 mm.

[0065] Films prepared by electrospinning polycaprolactone (Shenzhen Boli Biomaterials Co., Ltd.), with a film thickness of 40 μm. The film was made into thin strips with a width of 3 mm and a length of 1000 mm.

[0066] Two kinds of thin strips of 3mm x 1000mm face down, the hydrophilic thin strips are arranged horizont...

Embodiment 3

[0073] (1) Preparation of the inner layer: the inner layer material is polycaprolactone (Shenzhen Boli Biomaterials Co., Ltd.), which is dissolved in hexafluoroisopropanol (Suzhou Haofan Biological Co., Ltd.), and the concentration of the spinning solution is 5% wt, stirred for 4 hours, electrospinning parameters were flow rate 1.0ml / h, voltage 15kV, receiving distance 25cm, electrospinning 5h.

[0074] (2) Preparation of the middle layer.

[0075] Films prepared by electrospinning carboxymethyl chitosan (Nantong Lvshen Bioengineering Co., Ltd.) with a film thickness of 40 μm. The film was made into thin strips with a width of 3 mm and a length of 1000 mm.

[0076] Films prepared by electrospinning polycaprolactone (Shenzhen Boli Biomaterials Co., Ltd.), with a film thickness of 40 μm. The film was made into thin strips with a width of 3 mm and a length of 1000 mm.

[0077] Two kinds of thin strips of 3mm x 1000mm face down, the hydrophilic thin strips are arranged horizont...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com