Silver nano-particle hybrid supramolecular hydrogel based on cyclodextrin/PEG grafted polyacrylic acid, and preparation method and application thereof

A supramolecular hydrogel, grafted polyacrylic acid technology, applied to silver nanoparticle hybrid supramolecular hydrogel based on cyclodextrin/PEG grafted polyacrylic acid and the field of preparation and application, can solve the problem of gel performance, poor stability of silver nanoparticles, affecting antibacterial properties, etc., to achieve the effect of improving stability, simple preparation process, and solving agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

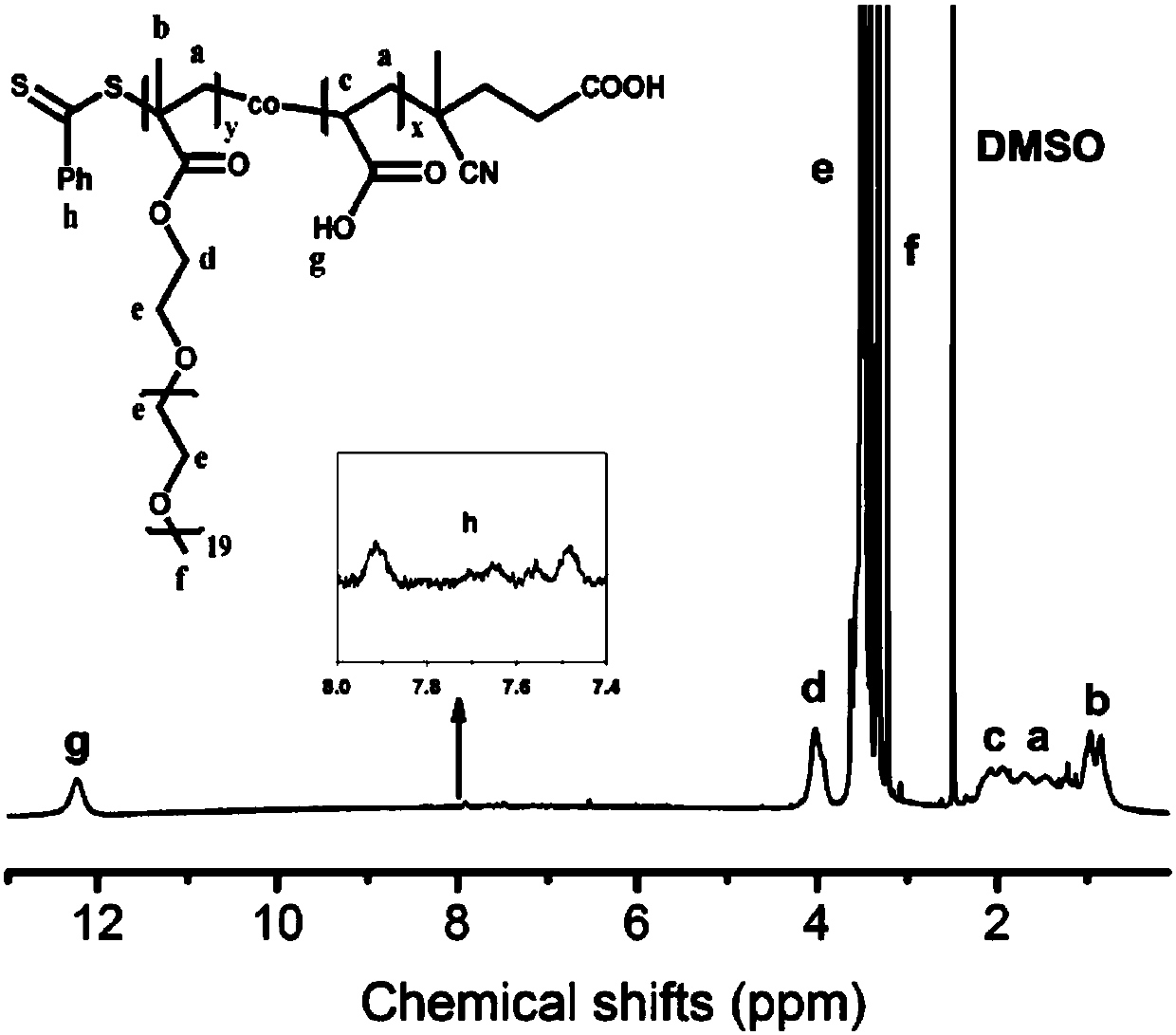

[0034] The structural formula of the anionic polyelectrolyte PPEGMA-co-PAA is:

[0035]

[0036] The synthetic method of polymer of the present invention, step is as follows:

[0037] PEGMA (2.2g, 2.3mmol), AA (82μL, 1.2mmol), CPADB (9.6mg, 0.03mmol), AIBN (1.5mg, 0.01mmol) were added to a Schlenk polymerization bottle, and the mixture was dissolved in 3mL of purified toluene, Freeze-thaw cycles deoxygenated and filled with nitrogen, and reacted in an oil bath at 60°C for 5 hours under the protection of nitrogen. After the reaction, the reaction bottle was placed in an ice-water bath, and the stopper was opened to expose to the air to terminate the polymerization. The mixture was precipitated in a mixed solvent of diethyl ether / n-hexane to remove unreacted monomers, centrifuged to obtain a pink solid, and dried under vacuum at 35°C. (Mn, GPC =10.2K, PDI=1.21)

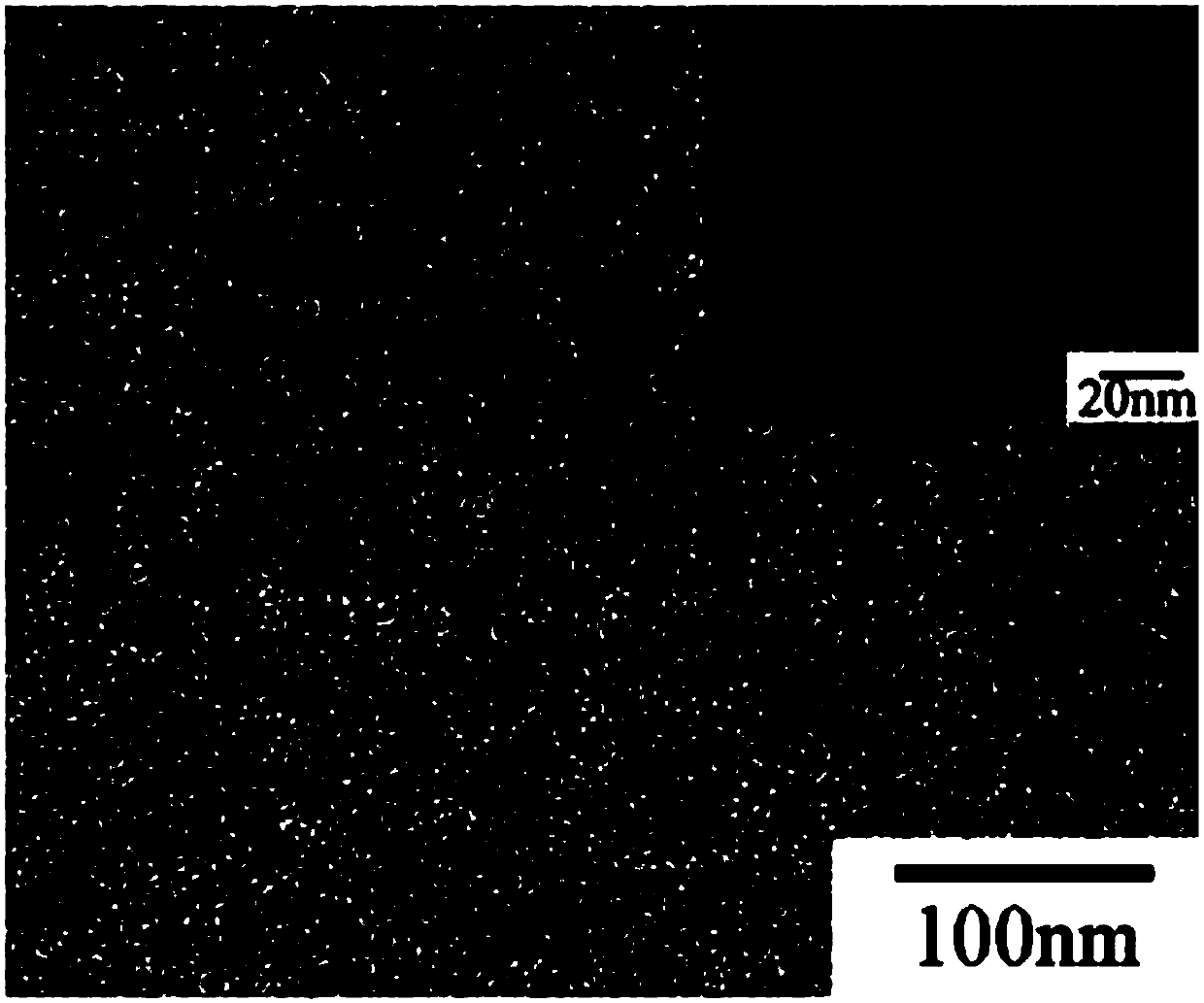

[0038] Weigh the polymer PPEGMA-co-PAA (236.3 mg, 0.06 mmol AA unit) and dissolve it in 10 mL of high-purity w...

Embodiment 2

[0042] PEGMA (2.2g, 2.3mmol), AA (238μL, 3.5mmol), CPADB (9.6mg, 0.03mmol), AIBN (1.5mg, 0.01mmol) were added to a Schlenk polymerization bottle, and the mixture was dissolved in 3mL of purified toluene, Freeze-thaw cycles deoxygenated and filled with nitrogen, and reacted in an oil bath at 60°C for 7 hours under the protection of nitrogen. After the reaction, the reaction bottle was placed in an ice-water bath, and the stopper was opened to expose to the air to terminate the polymerization. The mixture was precipitated in a mixed solvent of diethyl ether / n-hexane to remove unreacted monomers, centrifuged to obtain a pink solid, and dried under vacuum at 35°C. (Mn, GPC =30.3K, PDI=1.19)

[0043] The polymer PPEGMA-co-PAA (78.8mg, 0.08mmol AA unit) was weighed and dissolved in 10mL of high-purity water, 0.025M silver nitrate aqueous solution (1mL) was added thereto, and stirred at room temperature for 0.5h at high speed. The freshly prepared 0.25M sodium borohydride aqueous ...

Embodiment 3

[0047] Add PEGMA (4.4 g, 4.6 mmol), AA (1.25 mL, 18.4 mmol), CPADB (9.6 mg, 0.03 mmol), AIBN (1.5 mg, 0.01 mmol) into a Schlenk polymerization flask, and dissolve the mixture in 10 mL of purified toluene , deoxygenated and nitrogen-filled by freeze-thaw cycles, and reacted in an oil bath at 60°C for 8 hours under the protection of nitrogen. After the reaction, the reaction bottle was placed in an ice-water bath, and the stopper was opened to expose to the air to terminate the polymerization. The mixture was precipitated in an excess of diethyl ether / n-hexane mixed solvent to remove unreacted monomers, and centrifuged to obtain a pink solid, which was vacuum-dried at 35°C. (Mn, GPC =600.1K, PDI=1.37)

[0048] The polymer PPEGMA-co-PAA (35.0mg, 0.08mmol AA unit) was weighed and dissolved in 10mL of high-purity water, 0.025M silver nitrate aqueous solution (1mL) was added thereto, and stirred at room temperature for 0.5h at high speed. The freshly prepared 0.25M sodium borohyd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com