Dopo-containing imidazole sulfonate ionic liquid flame retardant, preparation method and application

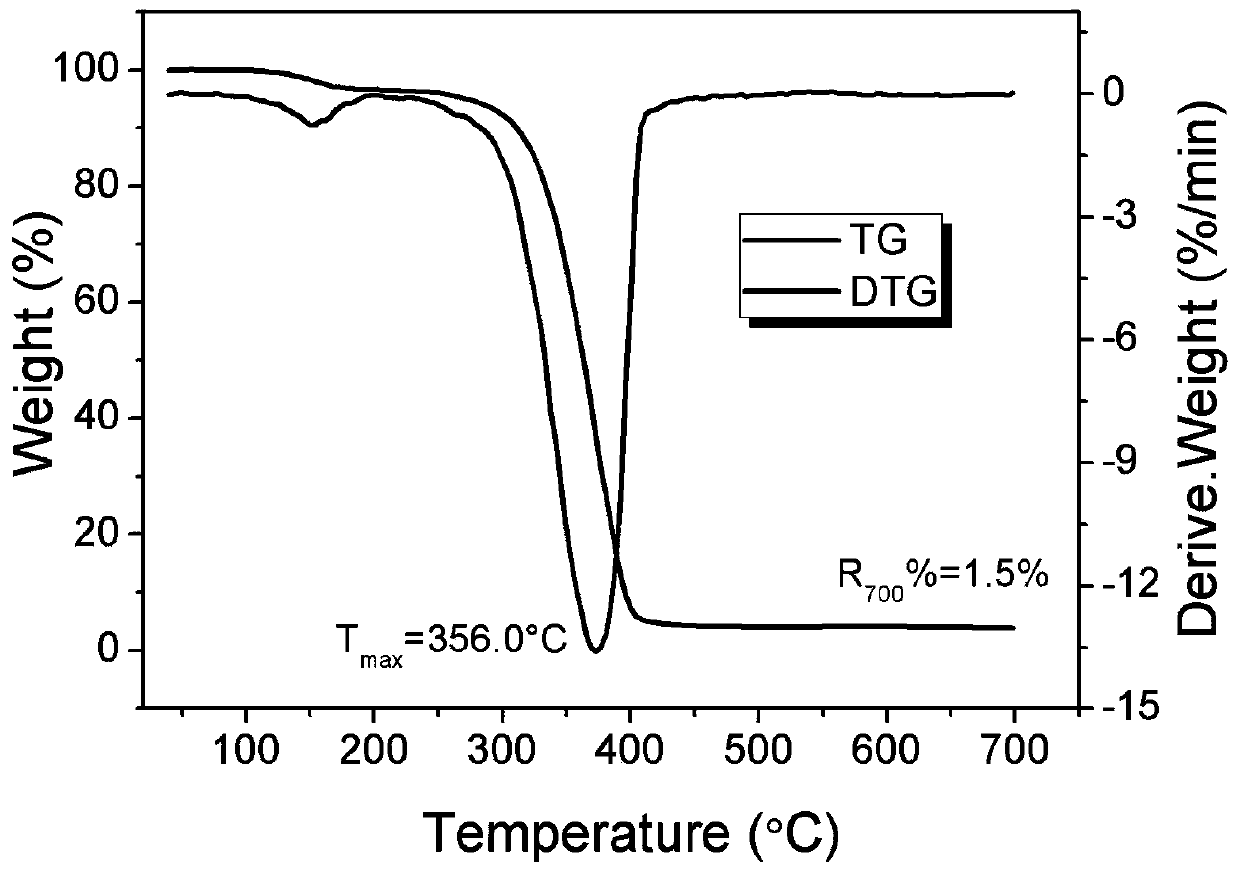

A technology of imidazole sulfonate and ionic liquid, which is applied in the field of flame retardancy, can solve the problems of poor compatibility and the decline in the mechanical properties of flame-retardant epoxy, and achieve a wide range of raw material sources, excellent thermal stability, and high yield. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

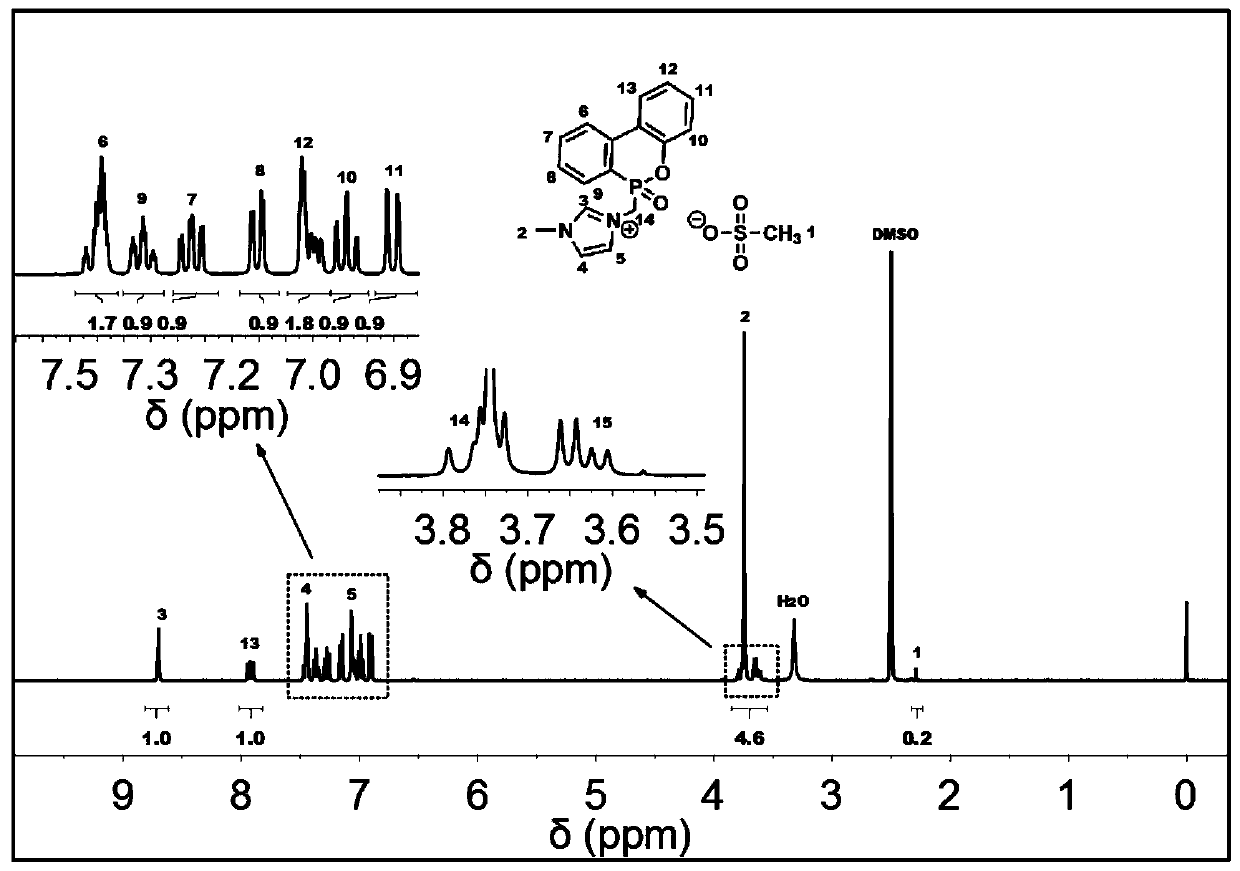

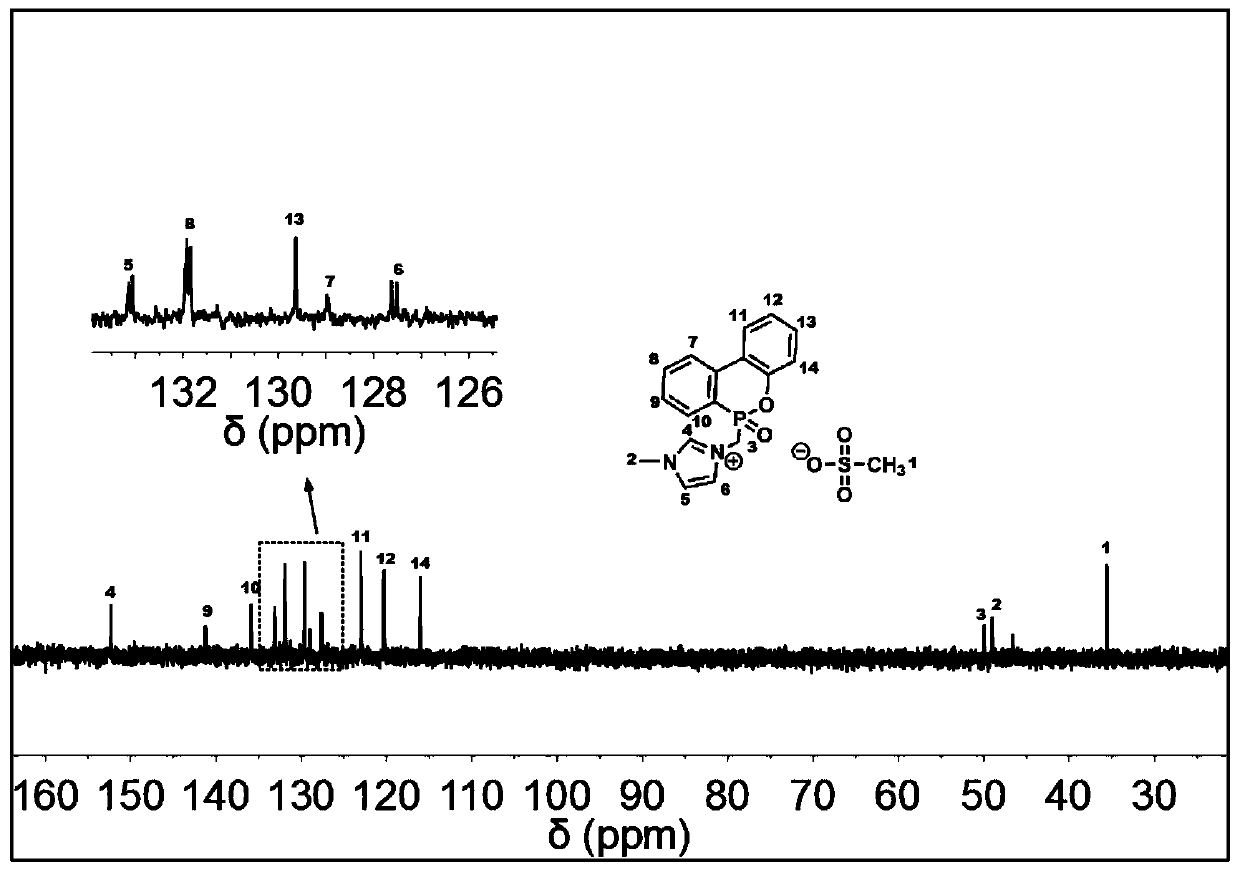

Method used

Image

Examples

Embodiment 1

[0042] 1) in N 2Under protection, add 1mol DOPO into 500ml solvent xylene, raise the temperature to 90°C, and mechanically stir for 30 minutes. After DOPO is completely dissolved in xylene, continue stirring for 10 minutes, and then slowly add 1mol~2mol of paraformaldehyde to maintain at React at 80°C for 5h to 8h. After the reaction, filter with suction and wash with deionized water for 3 to 5 times. A clean white sandy solid was obtained, irradiated by an infrared lamp for 4-6 hours, and then dried in a vacuum oven at 80° C. for 10 hours, with a yield of 96%. It was named DOPO-OH, and its structure was as follows:

[0043]

[0044] 2) in N 2 Under protection, dissolve 0.5mol DOPO-OH in 200ml dichloromethane, add 0.5mol triethylamine, stir mechanically at a rate of 400r / min for 10min, then slowly add 0.5mol methanesulfonyl chloride dropwise with a dropping funnel, drop The addition time was controlled within 1 hour, and after the dropwise addition, the reaction was carr...

Embodiment 2

[0050] 1) in N 2 Under protection, add 1mol DOPO (9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide) into 500ml solvent xylene, heat up to 90°C, stir mechanically for 30min, and wait until DOPO is completely Dissolve in toluene, continue to stir for 10 minutes, then slowly add 1 mol of paraformaldehyde, and maintain the reaction at 80°C for 5h to 8h. After the reaction, filter with suction and wash with ethanol for 3 to 5 times. A clean white sandy solid was obtained, which was dried under infrared light for 4-6 hours, and then dried in a vacuum oven at 80°C for 10 hours, with a yield of 96%. It was named DOPO-OH, and its structure was as follows:

[0051]

[0052] 2) in N 2 Under protection, dissolve 0.5mol DOPO-OH in 200ml acetonitrile, add 0.5mol triethylamine, stir mechanically at a rate of 400r / min for 10min, then slowly add 0.5mol p-toluenesulfonate dissolved in acetonitrile dropwise with a dropping funnel Acyl chloride, the dropwise addition time is controlled wi...

Embodiment 3

[0058] 1) in N 2 Under protection, add 1mol DOPO to 500ml solvent xylene, raise the temperature to 90°C, and stir mechanically for 30min. After DOPO is completely dissolved in xylene, continue stirring for 10min, then slowly add 1mol of paraformaldehyde, and maintain at 80°C Under the conditions of reaction 5h ~ 8h. After the reaction, filter with suction and wash with deionized water for 3 to 5 times to obtain a clean white sandy solid. Dry it with an infrared lamp for 4 to 6 hours, and then dry it in a vacuum oven at 80°C for 10 hours. The yield is 96%. It is named DOPO-OH. The structure is as follows:

[0059]

[0060] 2) in N 2 Under the condition of protective gas, dissolve 0.5mol DOPO-OH in 200ml ethanol, add 0.5mol pyridine, stir mechanically at a rate of 400r / min for 10min, then slowly add 0.5mol propylsulfonyl chloride dropwise with a dropping funnel, drop Adding time was controlled within 1 hour, and after the dropwise addition, the reaction was carried out at ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com